A method for preventing mistakes and foolproofing of smt splicing materials

An error-proof and fool-proof technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of wrong material replacement and lack of fool-proof, and achieve the effect of avoiding replacement errors, ensuring consistency, and improving qualified yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

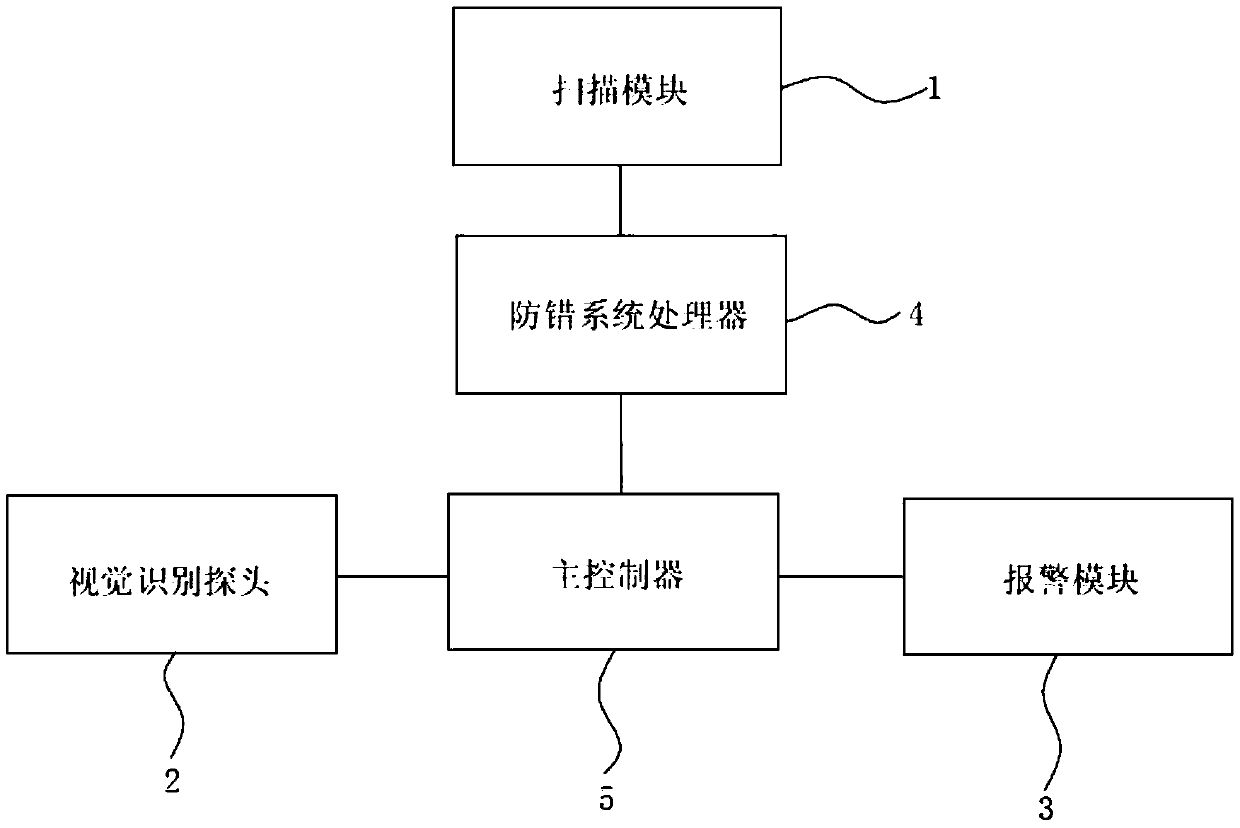

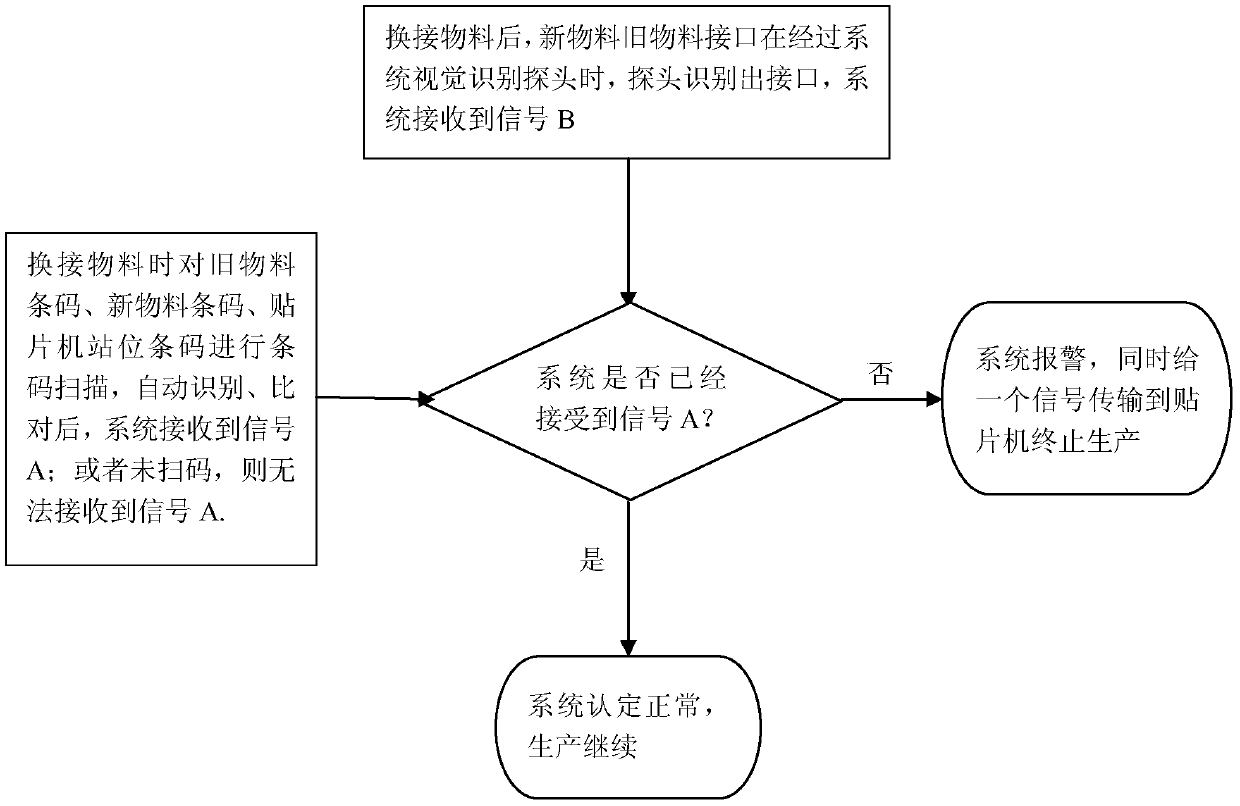

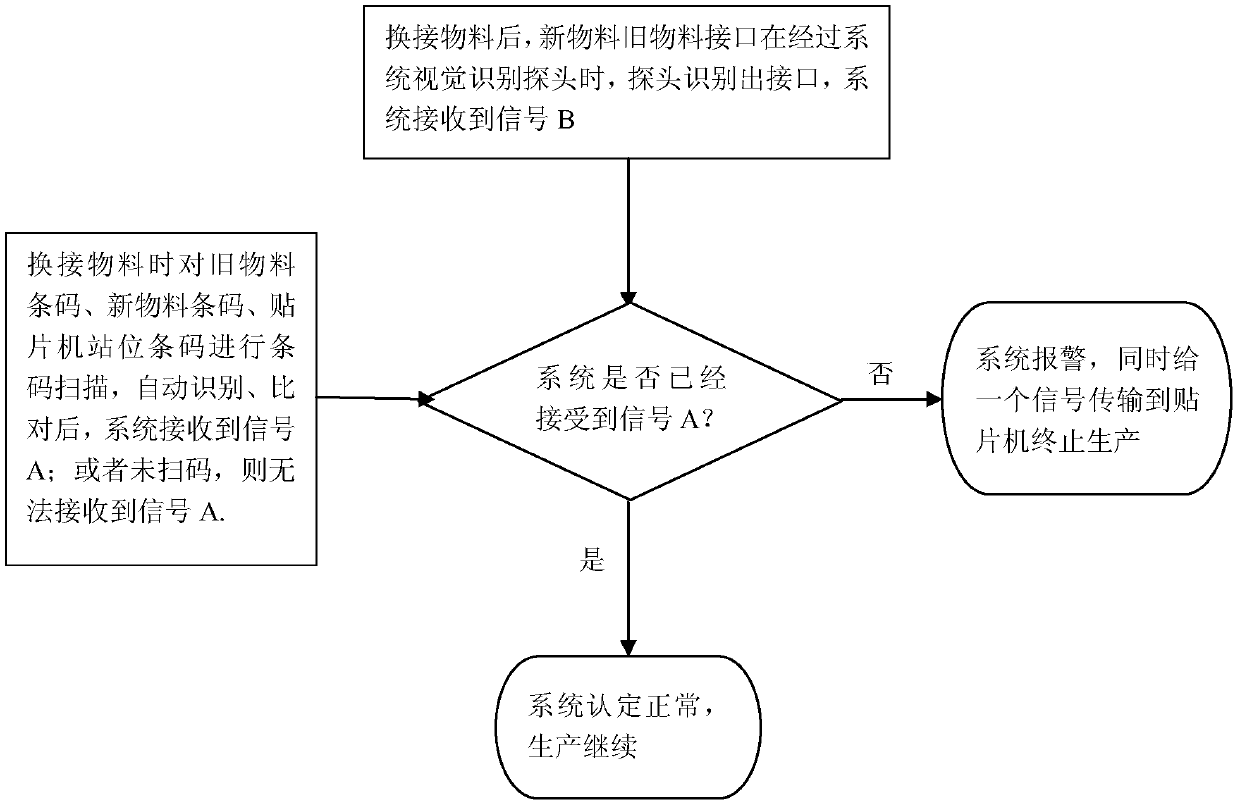

[0019] see figure 1 , a method for preventing mistakes and foolproofing of SMT replacement materials, the mistake-proofing system it adopts includes a scanning module 1, a visual recognition probe 2, an alarm module 3, a mistake-proofing system processor 4 and a main controller 5, wherein the scanning module 1 is connected to the error-proofing system processor 4, the error-proofing system processor 4 and the visual recognition probe 2 are respectively connected to the input end of the main controller 5, and the alarm module 3 is connected to the output end of the main controller 5.

[0020] The method of preventing mistakes and foolproofing SMT replacement materials includes the following steps:

[0021] 1) When changing materials, use the scanning module 1 to scan the old material barcode, new material barcode, and placement machine station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com