A joint connection method of vertical prefabricated components

A vertical component and node connection technology, applied in the direction of building structure, construction, etc., can solve the problems of difficult to guarantee construction quality, high construction cost and high process requirements, and achieve a simplified way of precast concrete vertical prefabricated component node connection, Improve construction quality and strengthen the effect of overall connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

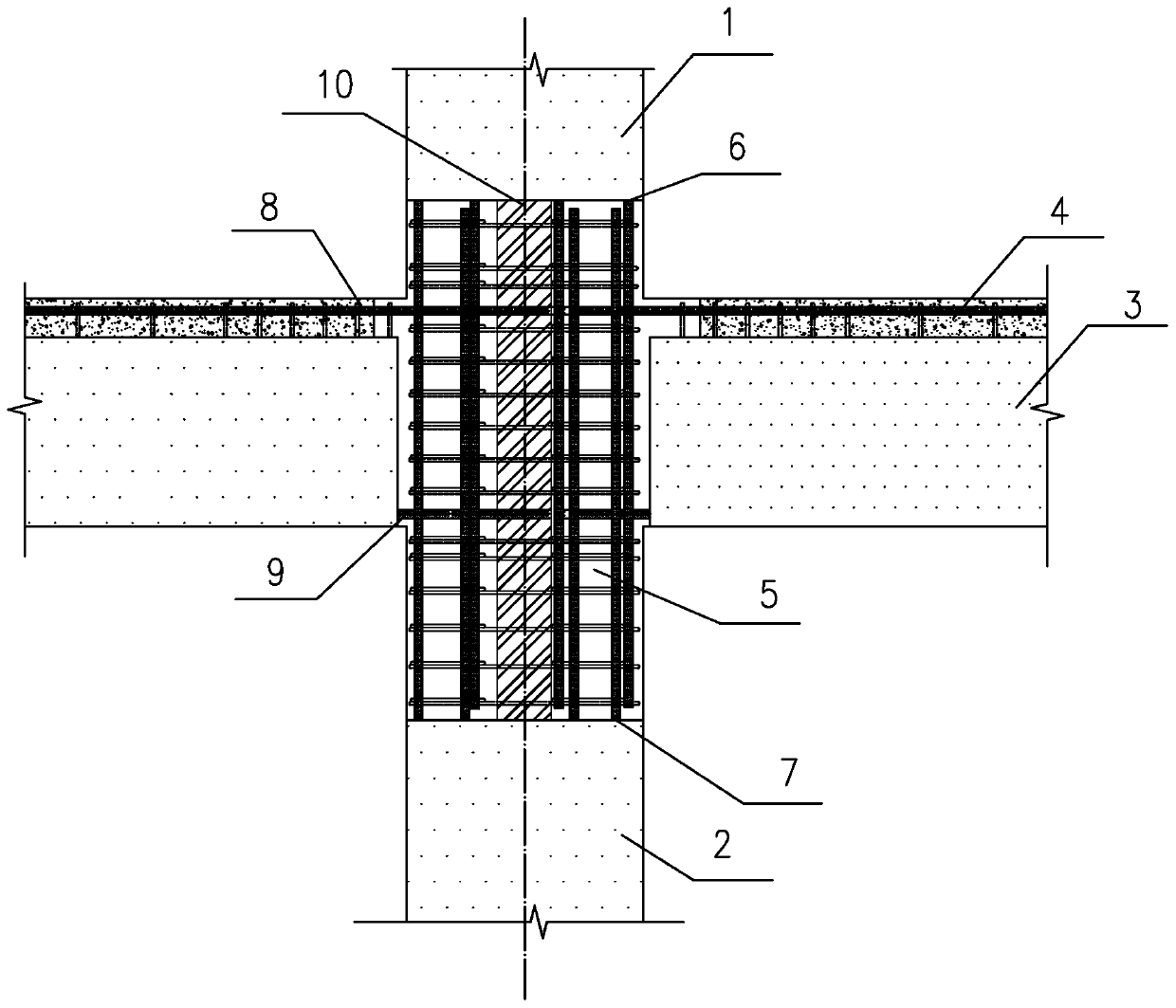

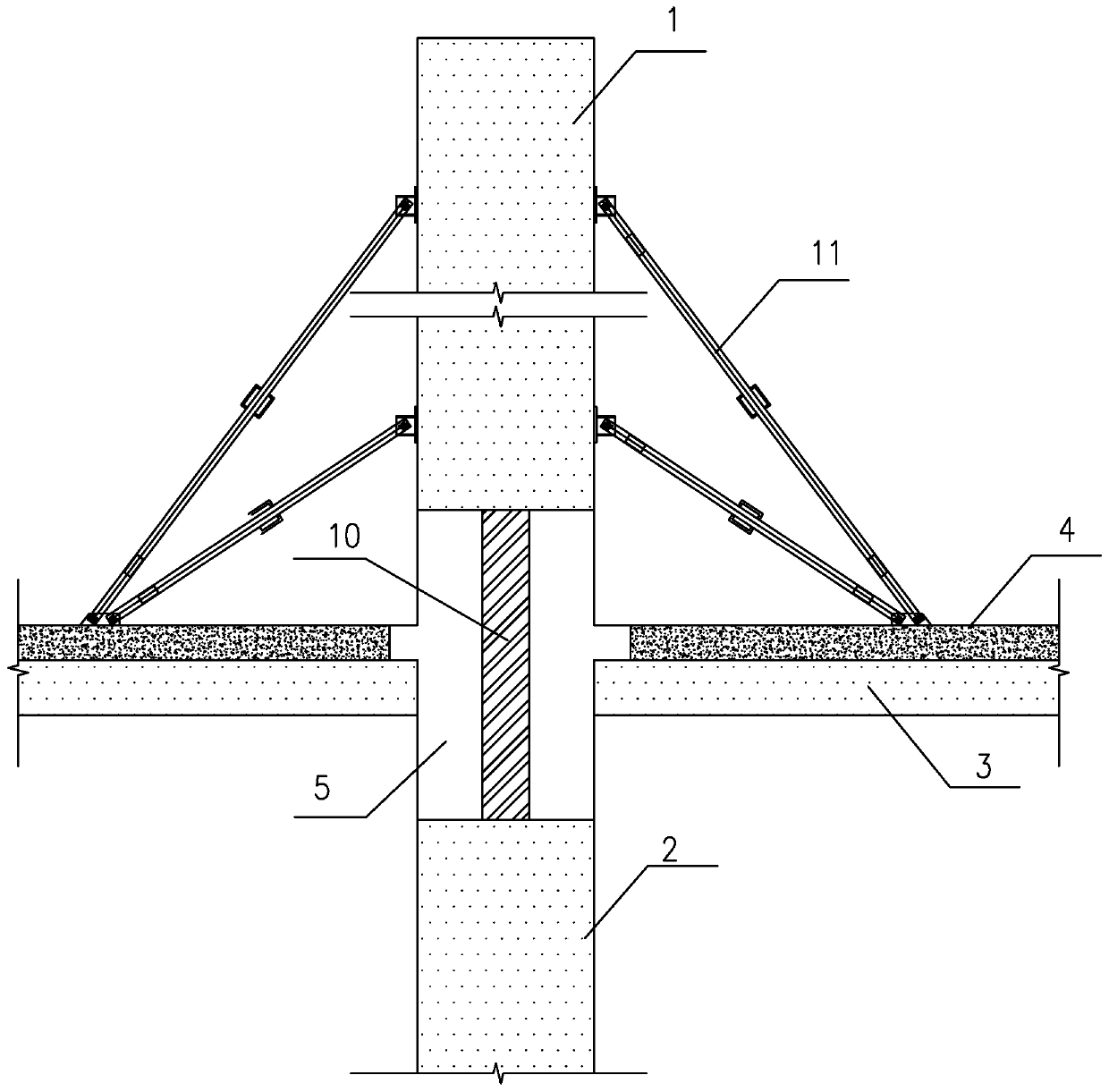

[0024] Such as figure 1 and 2 As shown, in this embodiment, the precast concrete horizontal component is a precast concrete composite beam slab 3, and the precast concrete vertical component is a precast concrete frame column, that is, the upper precast concrete frame column 1 and the lower precast concrete frame column 2. The nodes of an embodiment are frame column mid-level nodes.

[0025] A novel vertical prefabricated member node connection method specifically includes the following steps:

[0026] (1) Hoist the precast concrete composite beam slab 3 to the installation position, bind the gluten 8 of the precast concrete composite beam slab 3 on the upper surface of the precast concrete composite beam slab 3, adjust the bottom rib 9 of the precast concrete composite beam slab 3 and the The positions of the longitudinal reinforcement 7 of the concrete frame column 2 and the longitudinal reinforcement 6 of the upper precast concrete frame column 1. The anchorage length of...

Embodiment 2

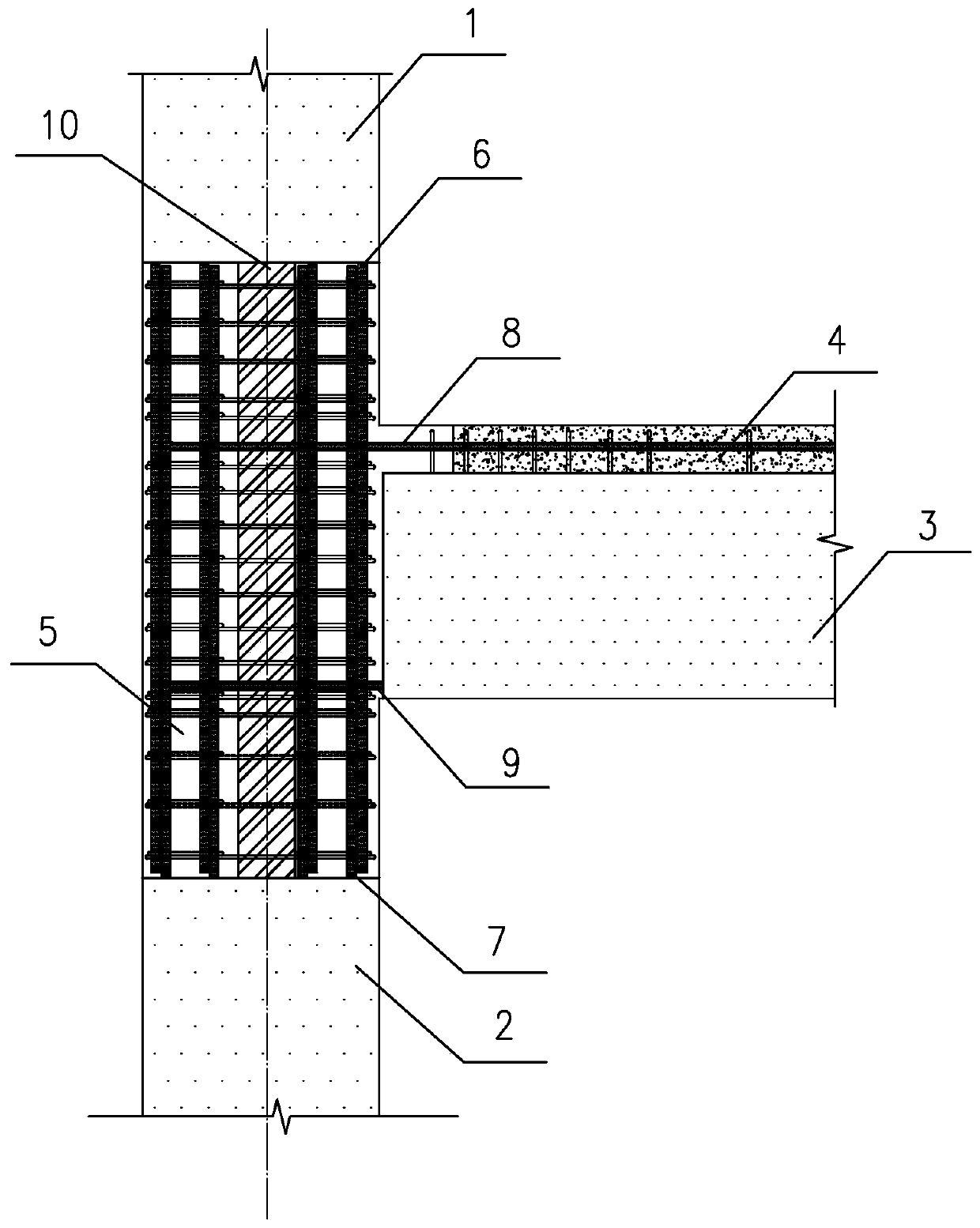

[0031] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the node of this embodiment is the edge node of the middle layer of the frame column. From a structural comparison, except for the reduction of the one-time concrete pouring area 4, the construction steps of this embodiment are the same as those of the implementation The construction steps of Example 1 are exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com