Rapid connection type coupling

A technology of couplings and connecting cylinders, which is applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., and can solve the problems of slow connection speed of assembly and disassembly, complex structure of couplings, and inability to adapt to quick connection and disassembly, etc. , to achieve the effect of quick disassembly and quick assembly and disassembly connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

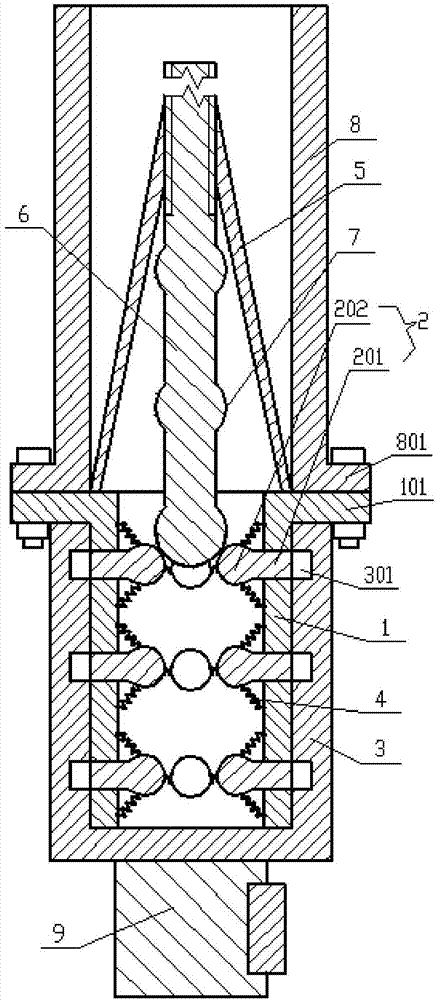

[0017] Such as figure 1 As shown, a quick-connect coupling includes a multi-position trigger mechanism and an insertion sleeve 3; the multi-position trigger mechanism includes a hollow body 1, and the body 1 is provided with a multi-layer contact handle 2 from top to bottom, The handle 2 includes an integrated cylindrical sliding post 201 and a spherical contact ball 202, the contact ball 202 is located in the through hole of the body 1, and the sliding post 201 horizontally protrudes from the outer wall of the main body 1; the contact handle 2 is The center of the through hole is arranged in a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com