Three-dimensional design method for turbomachinery impeller with castability

A turbomachinery, three-dimensional design technology, applied in the direction of mechanical equipment, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of increasing the difficulty of manufacturing and processing costs, and achieve high efficiency, energy saving, cost, and complete castability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] A three-dimensional design method of a castable turbomachinery impeller, suitable for the three-dimensional design of centrifugal or radial flow, mixed flow or oblique flow turbomachinery impellers, the impeller can be closed or semi-open, and the fluid medium It can be liquid single-phase, gas (steam) liquid two-phase, gas (steam) liquid-solid multi-phase or gas single-phase.

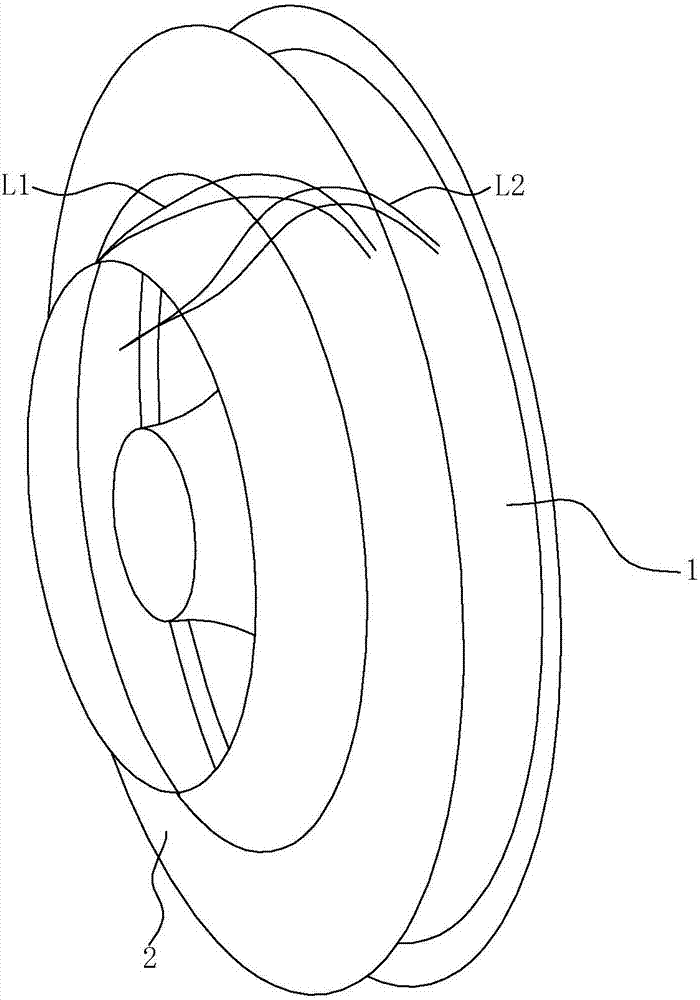

[0028] see Figure 6 , the turbomachinery impeller includes a castable impeller body, the impeller body includes a disc 1, a wheel cover 2 and at least two blades 3, and each blade 3 is the same three-dimensional space twisted blade. The above wheel disk 1 , wheel cover 2 and blade 3 can be cast to form a three-dimensional space twisted impeller flow path between the impeller inlet in the impeller body 1 , the impeller outlet and the blade 3 .

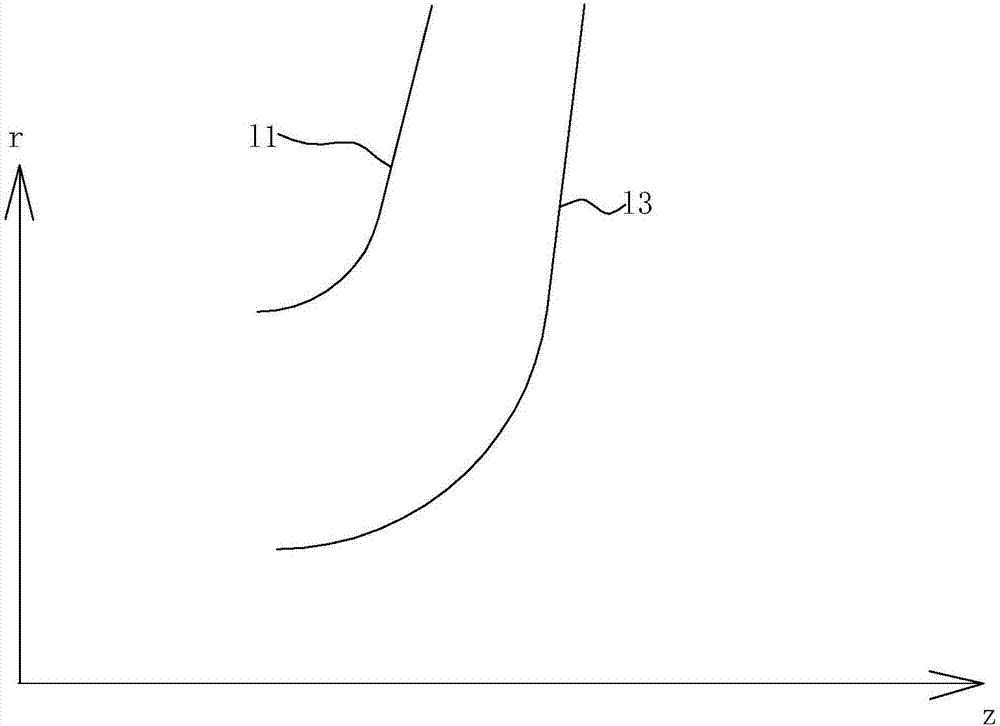

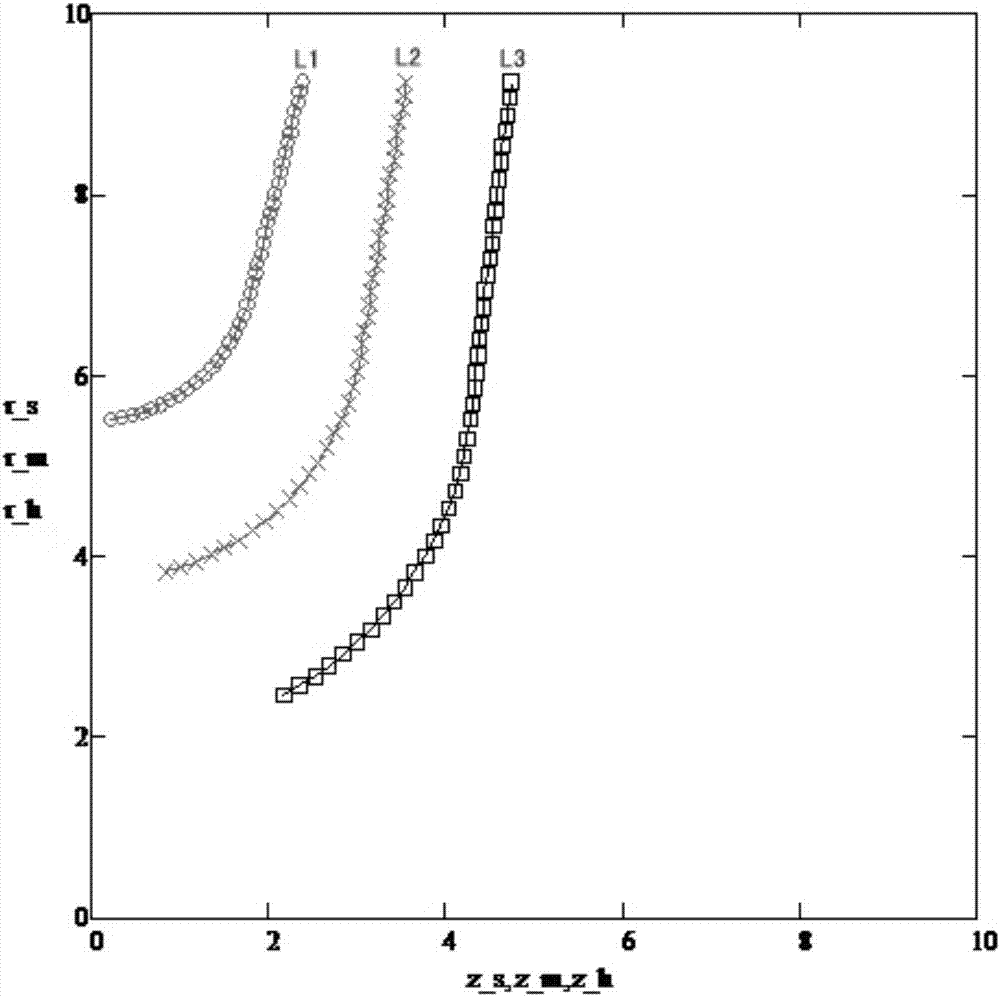

[0029] The thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com