Double rotary noodle pulling machine

A noodle machine and rotary motion technology, applied in dough forming machinery or equipment, baking, food science, etc., can solve the problems of inability to start, expensive construction, lack of intelligent platform, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

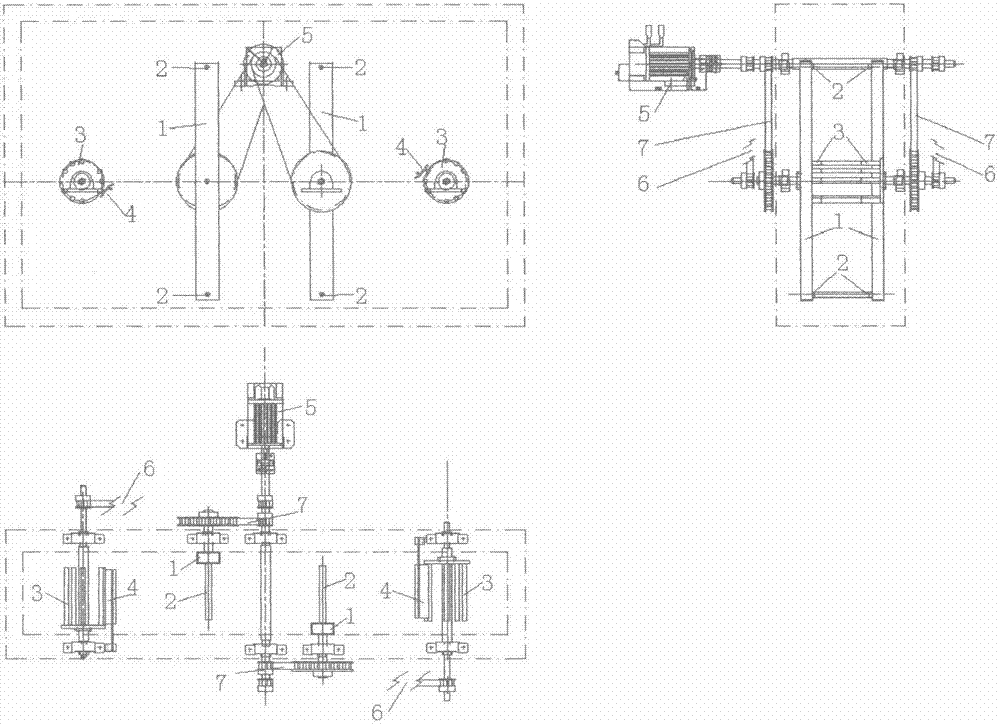

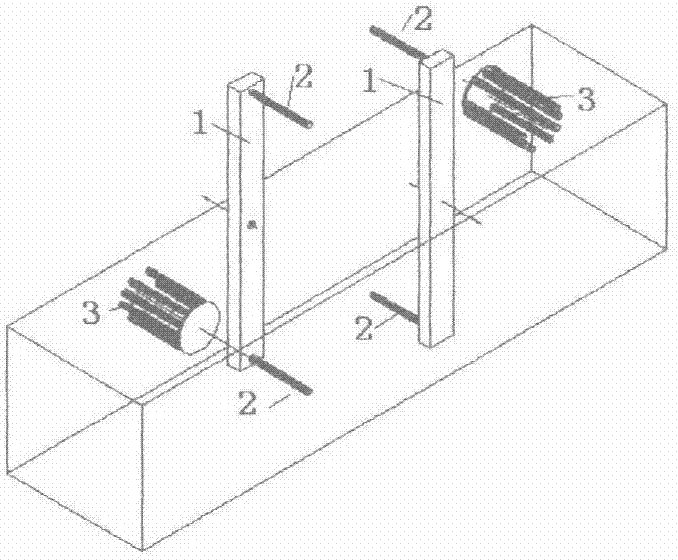

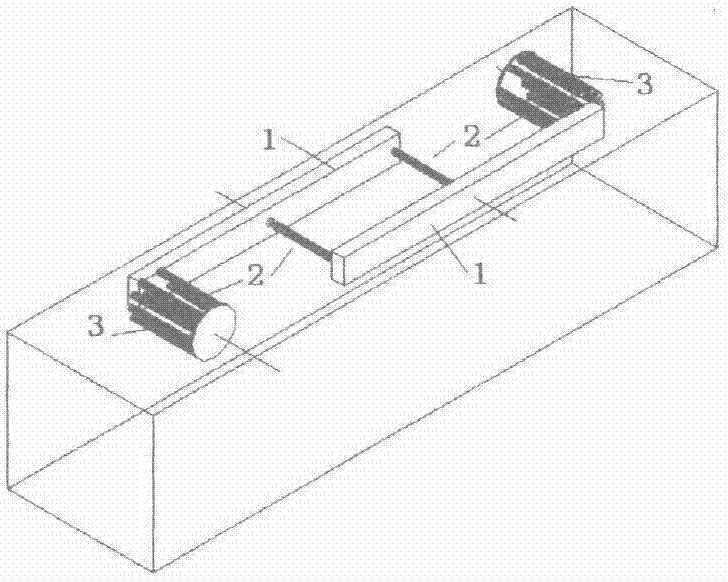

[0021] Such as figure 1 In the shown embodiment, when two pivoting arms (1) turn to the vertical position, the relative positions of pivoting arm (1), pull bar (2) and transfer cage (3) are as follows: figure 2 shown. When the two rotating arms (1) turn to the horizontal position, their relative positions are as follows: image 3 As shown, at this moment, a pull bar (2) is respectively arranged on the two rotating arms (1) to pass through the transfer cage (3).

[0022] Figure 4 , 5, 6 are the decomposition steps of the working process, the upper part is the front view, and the lower part is the top view. Figure 4 Step #1, the rotating arm (1) is in the vertical position, and the round strip-shaped noodle (8) (called a thick strip in the drawing process) is placed on the top of the upper two pull rods (2) in a diagonally pulled manner . The purpose of the inclined-pull feeding is to make the pulled noodles evenly distributed on the pull rod, and the noodles do not stic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com