Composite nanofiber membrane containing polysialic acid and preparation method and application

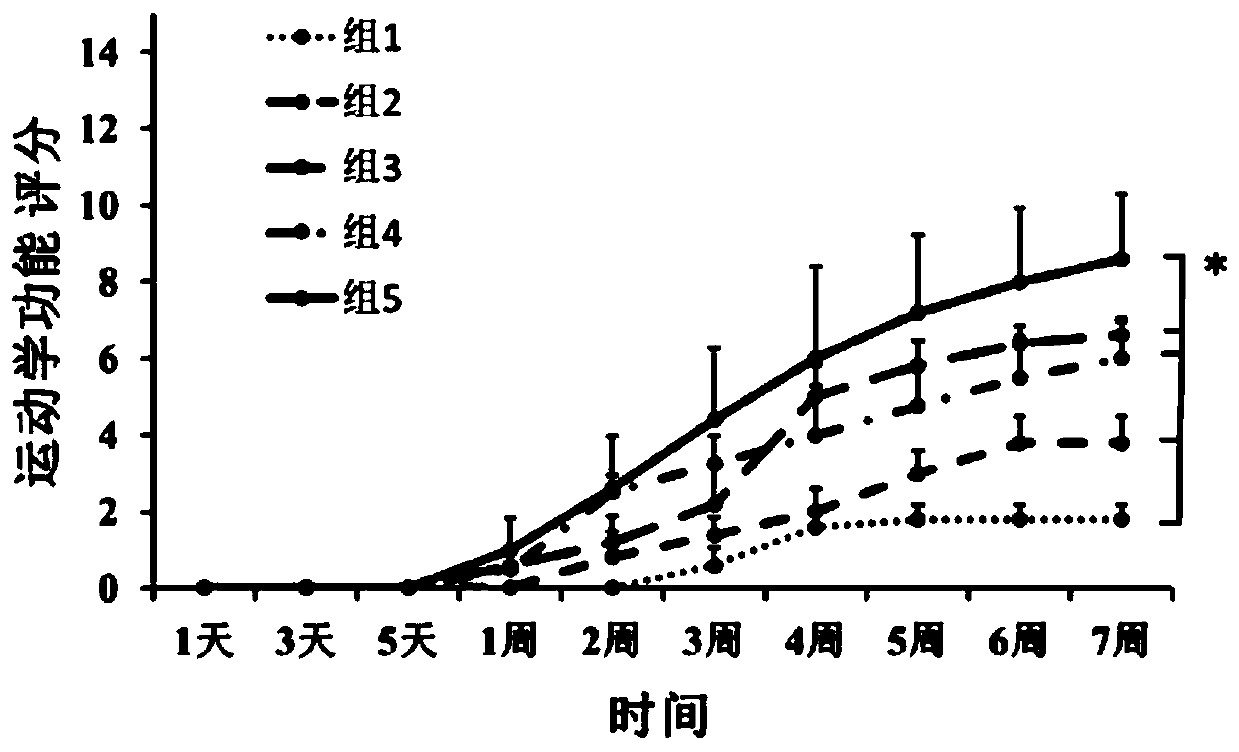

A technology of composite nanofibers and polysialic acid, which is applied in the field of tissue regeneration in biomedical engineering, can solve the problems of increased surgical risk, patient pain, and incomplete self-degradation, and achieves the improvement of kinematic function, high similarity, and promotion of The effect of nerve fiber repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 1g of tetrabutylammonium bromide and dissolve it in 20ml of deionized water, add 1g of cation exchange resin (Dowex50WX2), stir at room temperature for 2h, collect the cation exchange resin by centrifugation, and wash 3 times with deionized water; then, weigh 200mg The polysialic acid (weight-average molecular weight is 5000Da) is dissolved in 20ml of deionized water, add the cation exchange resin collected above, and stir at room temperature for 2h, remove the cation exchange resin by centrifugation, take the supernatant, and wash the resin with deionized water for 3 The second time, the washing solution was combined into the supernatant, and freeze-dried to obtain tetrabutylammonium bromide-modified polysialic acid. The weight-average molecular weight was 8560 as measured by gel permeation chromatography.

Embodiment 2

[0024] Weigh 1g of tetrabutylammonium bromide and dissolve it in 20ml of deionized water, add 1g of cation exchange resin (Dowex50WX2), stir at room temperature for 2h, collect the cation exchange resin by centrifugation, and wash 3 times with deionized water; then, weigh 600mg The polysialic acid (weight-average molecular weight is 12000Da) is dissolved in 20ml of deionized water, add the cation exchange resin collected above, and stir at room temperature for 2h, remove the cation exchange resin by centrifugation, take the supernatant, and wash the resin with deionized water for 3 The second time, the washing solution was combined into the supernatant, and freeze-dried to obtain tetrabutylammonium bromide-modified polysialic acid. The weight-average molecular weight measured by gel permeation chromatography was 22400Da.

Embodiment 3

[0026] Weigh 1g of tetrabutylammonium bromide and dissolve it in 20ml of deionized water, add 1g of cation exchange resin (Dowex50WX2), stir at room temperature for 2h, collect the cation exchange resin by centrifugation, and wash 3 times with deionized water; then, weigh 950mg The polysialic acid (weight average molecular weight is 100000Da) is dissolved in the deionized water of 20ml, adds above-mentioned collected cation exchange resin, and stirs at room temperature 2h, removes cation exchange resin by centrifugation, takes supernatant, and washes resin 3 with deionized water The second time, the washing solution was combined into the supernatant, and freeze-dried to obtain tetrabutylammonium bromide-modified polysialic acid. The weight-average molecular weight was 185,000 Da as measured by gel permeation chromatography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com