Paint spraying device for wooden door

A wooden door and paint storage technology, which is applied in the direction of spraying devices and liquid spraying devices, can solve the problems of asynchronous displacement mechanism and painting mechanism, uneven painting, etc., and achieve the effects of saving cost and time, improving painting efficiency and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

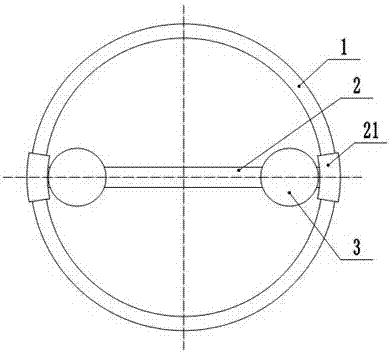

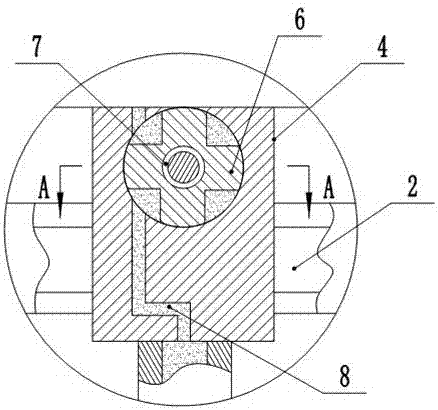

[0017] The reference signs in the accompanying drawings of the specification include: circular steel pipe frame 1, support foot 11, slide rod 2, paint storage box 3, slide seat 4, nozzle 5, runner 6, cylindrical end 61, open end 62, one-way bearing 7. Paint 8.

[0018] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

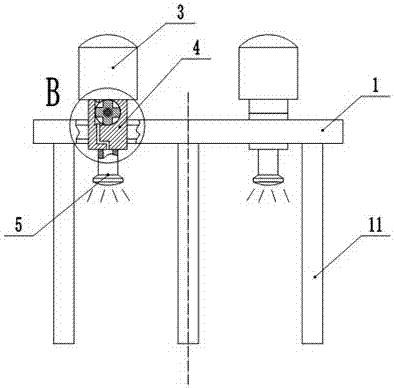

[0019] The wooden door painting device is mainly composed of a mounting frame and a painting mechanism, and the painting mechanism is movably connected on the mounting frame. The installation frame is composed of legs 11 and a circular steel pipe frame 1, several legs 11 are uniformly connected to the lower end of the circular steel pipe, and the two ends of the slide bar 2 are connected with arc-shaped sleeves, which are sleeved on the circular steel pipe frame 1 On, the painting mechanism is slidably connected on the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com