Clamp for concave workpiece

A workpiece fixture, concave technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of inability to clamp, position, inappropriate flat clamps, and inability to directly tighten, and achieve high precision and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

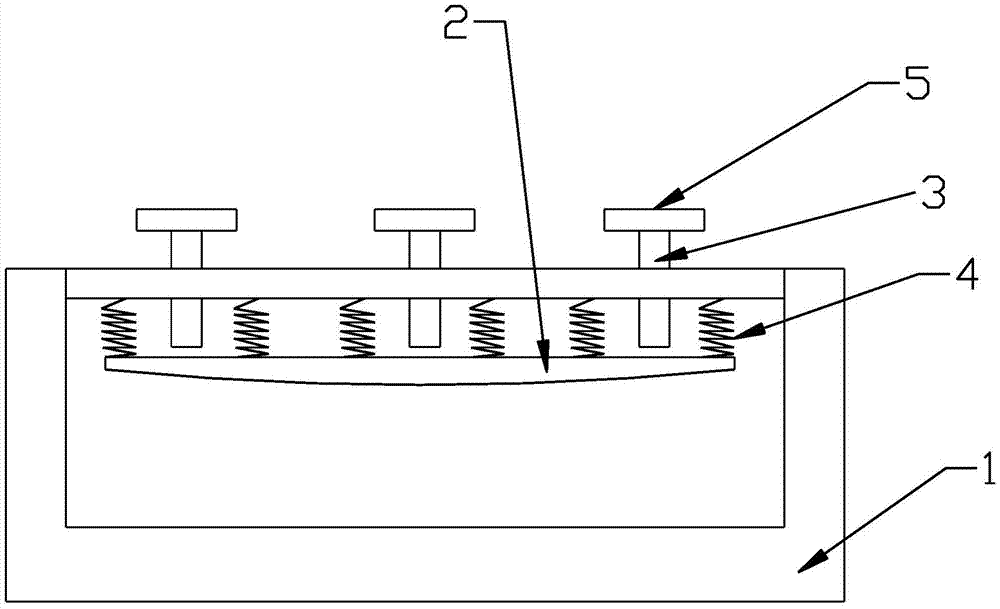

[0013] Such as figure 1 As shown, the present invention provides a concave workpiece fixture, including a base 1, an arc-shaped pressing plate 2, and a screw rod 3. The base 1 is a frame structure, and the arc-shaped pressing plate 2 has an arc surface that fits with the clamping surface of the workpiece. And the arc-shaped pressing plate 2 is arranged inside the base 1, a spring 4 is connected between the arc-shaped pressing plate 2 and the top plate of the base 1, the screw rod 3 is threadedly connected with the top plate of the base 1, and the outer end of the screw rod 3 A wrench 5 is provided, and the inner end is offset against the arc-shaped pressing plate 2 .

[0014] Further, in the above technical solution, the wrench 5 is provided with anti-skid lines.

[0015] Further, in the above technical solution, there are three screws 3 .

[0016] Further, in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com