Trailer wagon tensioning device for large-size tower crane

A technology for towing trolleys and tensioning devices, which is applied in cranes, transportation and packaging, etc. It can solve the problems of difficult manual movement, complex structure, and inability to continuously tension, etc., and achieves the effects of flexible and convenient operation, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0025] The present invention cancels the original tensioning device arranged on the luffing trolley, changes the multi-ratio pulley block into a 2-ratio pulley block, and changes intermittent tension to continuous tension.

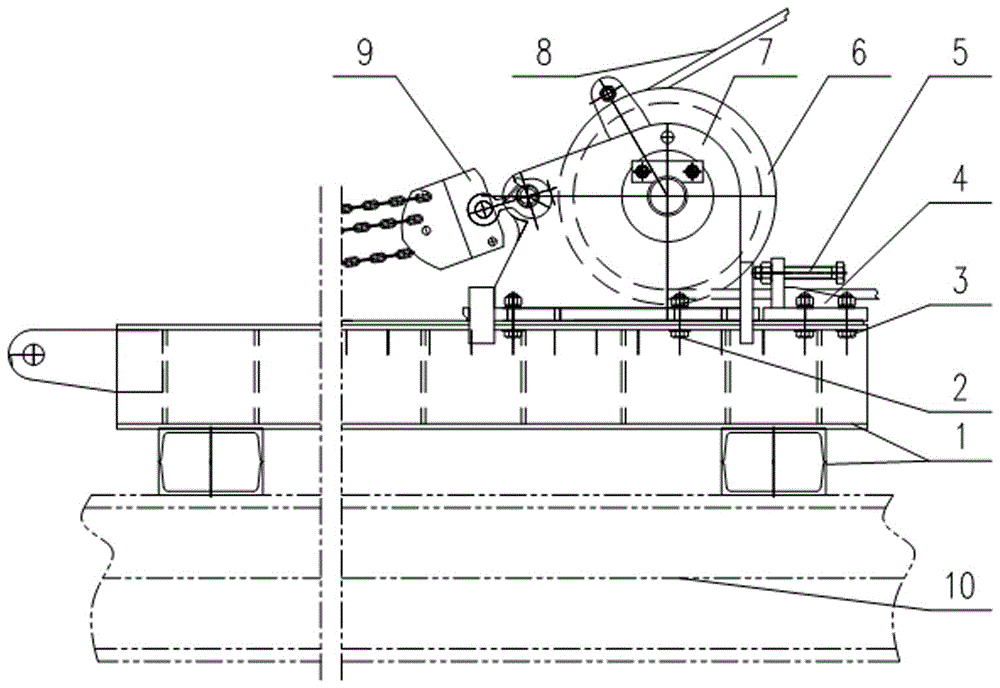

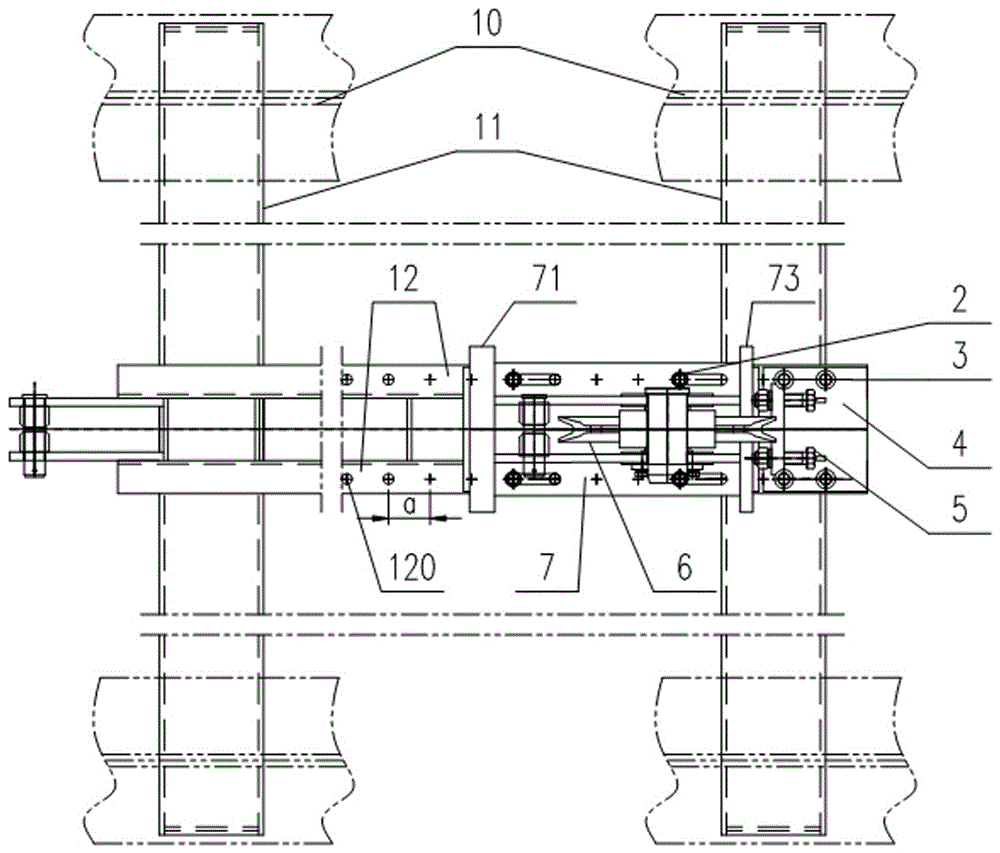

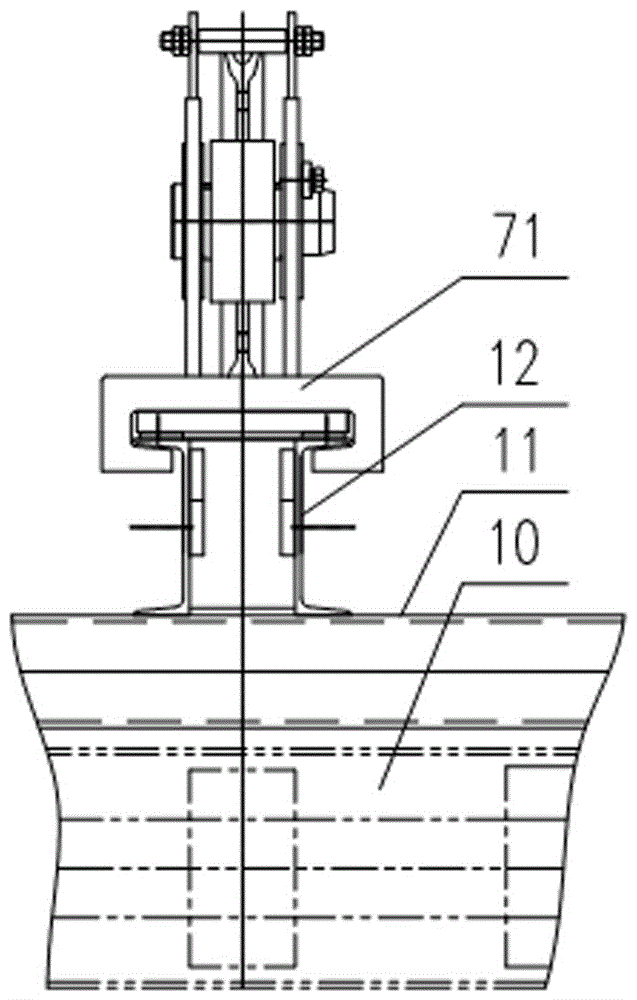

[0026] Specific examples figure 1 , 2 , 3, the large-scale tower crane traction trolley tensioning device of the present invention comprises the fixed frame 1 that is arranged on between two balance arms 10 and is made up of transverse beam frame 11 and longitudinal beam frame; Described transverse beam frame 11 is made up of The two ends are respectively affixed to the corresponding end balance arm 10 and constitute two parallel beams arranged; The track 12 is provided with a movable frame 7 that moves horizontally along the track 12, and the movable frame 7 is equipped with a pulley block 6 for tensioning and guiding the luffing wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com