A method for quickly tightening the screen and preventing the screen from falling, and a vibrating screen

A vibrating sieve and sieve technology, which is applied to chemical instruments and methods, sieves, solid separation, etc., can solve the problems of large impact on production and no good solution, and achieve good vibration transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

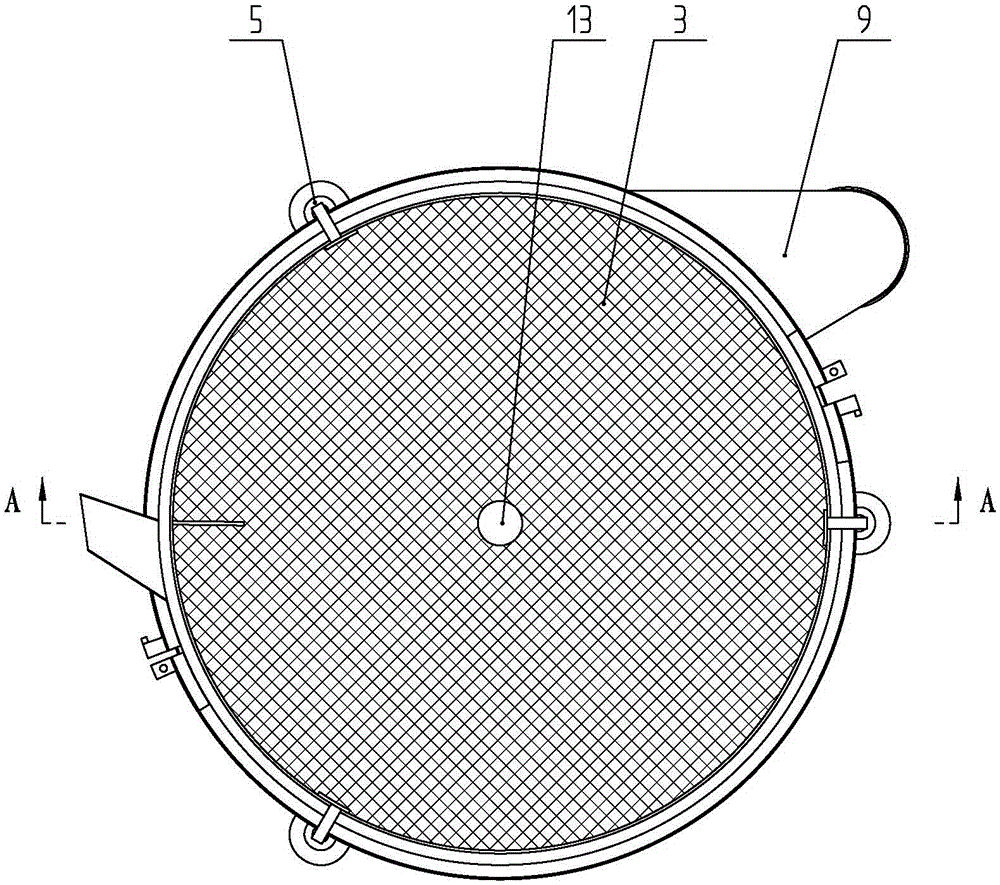

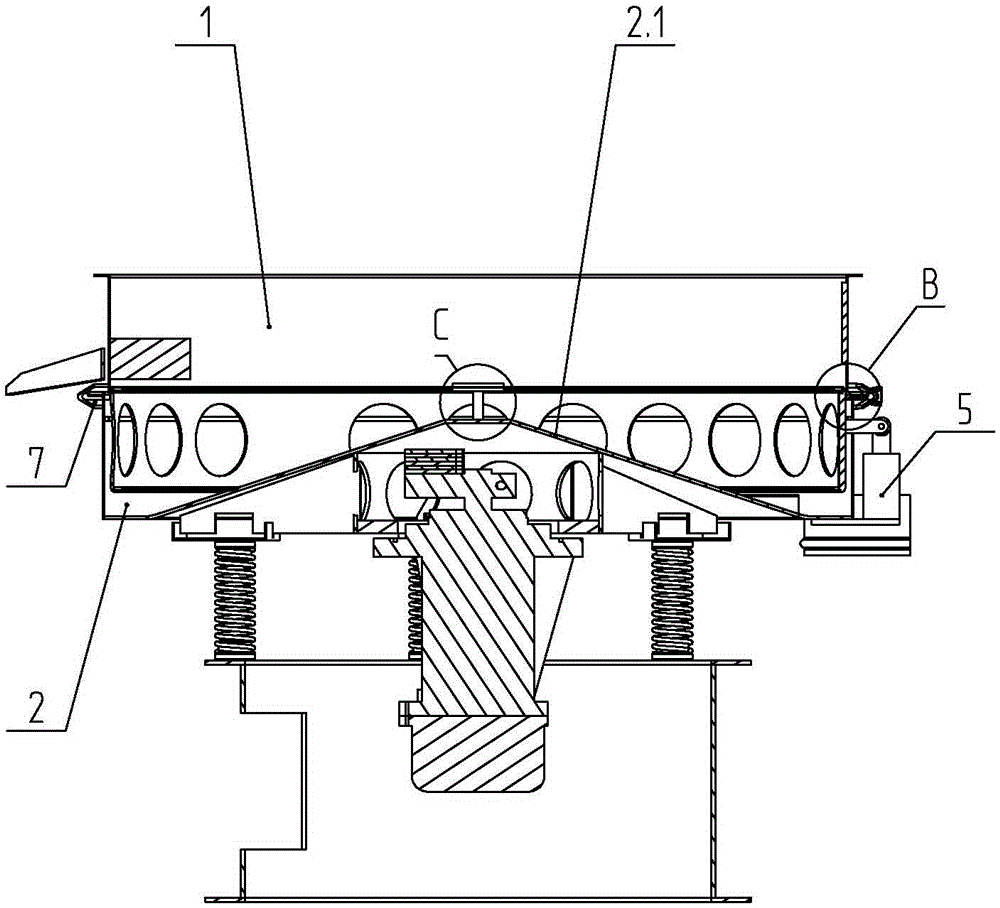

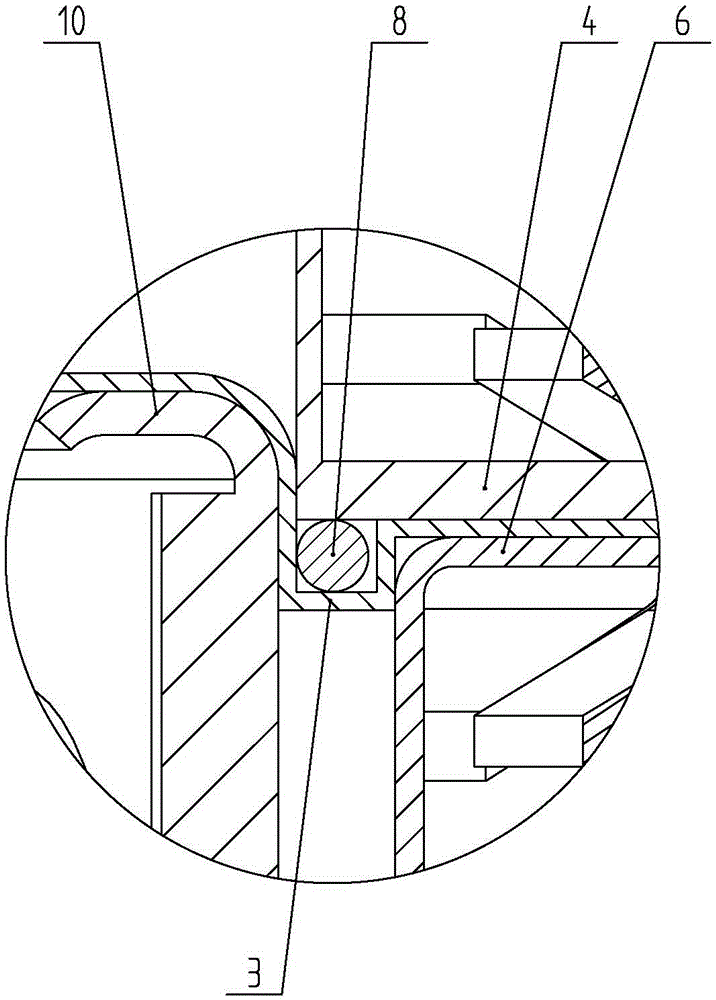

[0033] Such as Figures 1 to 3 As shown, the main part of the vibrating screen includes an upper screen frame 1, a lower screen frame 2, a screen 3, a press ring 8 and a tension ring 10. The tension ring 10 is arranged below the screen cloth 3 , and the press ring 8 is fixedly arranged at the bottom of the lower screen frame 2 . The connection between the upper and lower screen frames is provided with a flange structure. The specific connection method is that the lower end of the upper screen frame 1 is provided with a second flange 6, and the upper end of the lower screen frame 2 is provided with a first flange 4, a second flange 6 and The first flanges 4 are aligned, and the outer diameter of the upper screen frame 1 is smaller than the inner diameter of the lower screen frame 2 . The central position of the bottom surface of the lower screen frame 2 protrudes upwards to form a trapezoidal round platform 2.1, and the discharge port 9 is opened at the bottom of the lower scr...

Embodiment 2

[0044] Such as Figure 5 , 6 As shown, the difference from Embodiment 1 is that the lifter in this embodiment is a jack 14 . Jack 14 comprises base 14.1, two lower arms 14.2, two upper arms 14.3, leading screw 14.4, bearing pin 14.5 and bearing platform 14.6. The base 14.1 is fixed on the outer wall of the lower screen frame, and the carrying platform 14.6 is connected with one end of the top tight block. The upper end of upper arm 14.3 is all hinged on the bearing platform 14.6, the lower end of lower arm 14.2 is all hinged on the base 14.1; the lower end of upper arm 14.3 and the upper end of lower arm 14.2 are all hinged on pin 14.5. Leading screw 14.4 passes bearing pin 14.5 by thread fit mode; The upper end of each upper arm 14.3 and the lower end of each lower arm 14.2 all have the fan-shaped teeth that mesh with each other. When tightening the screen, turn the lead screw 14.4, and the distance between the two pin shafts 14.5 will decrease under the action of thread f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com