Connecting device for rod-shaped materials

A connecting device and rod-shaped technology, which is applied in the direction of construction and building construction, can solve the problems of complex connection mechanism structure, loose bamboo structure, and inability to adjust bamboo rods and bamboo rods arbitrarily, so as to achieve convenient use, strong stability, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

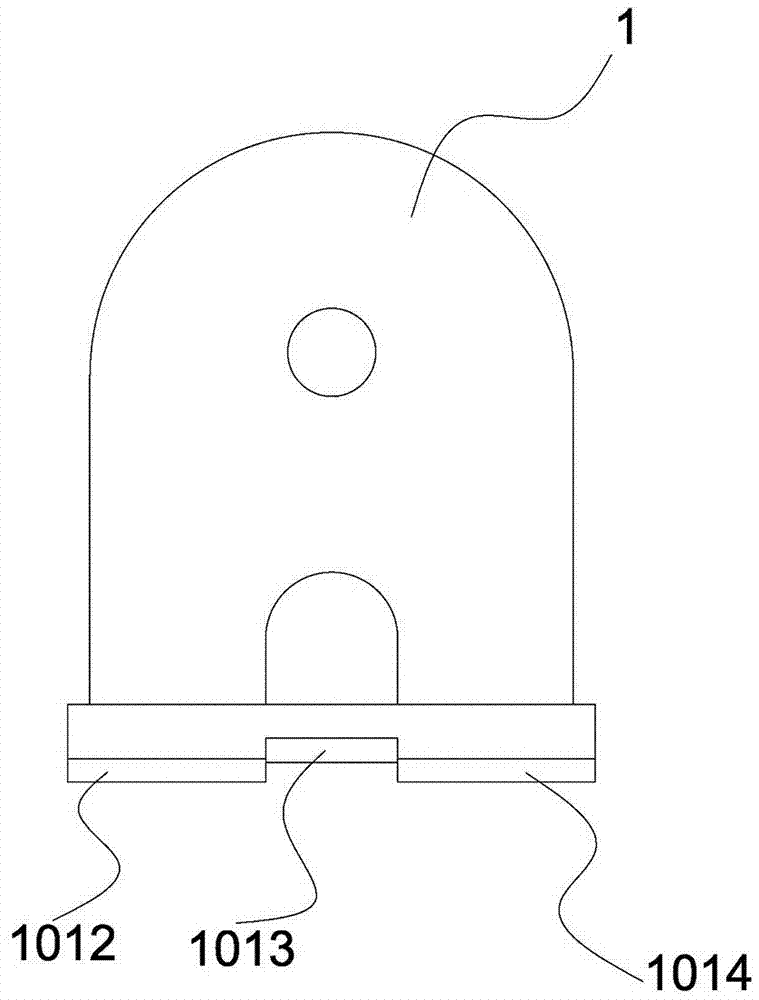

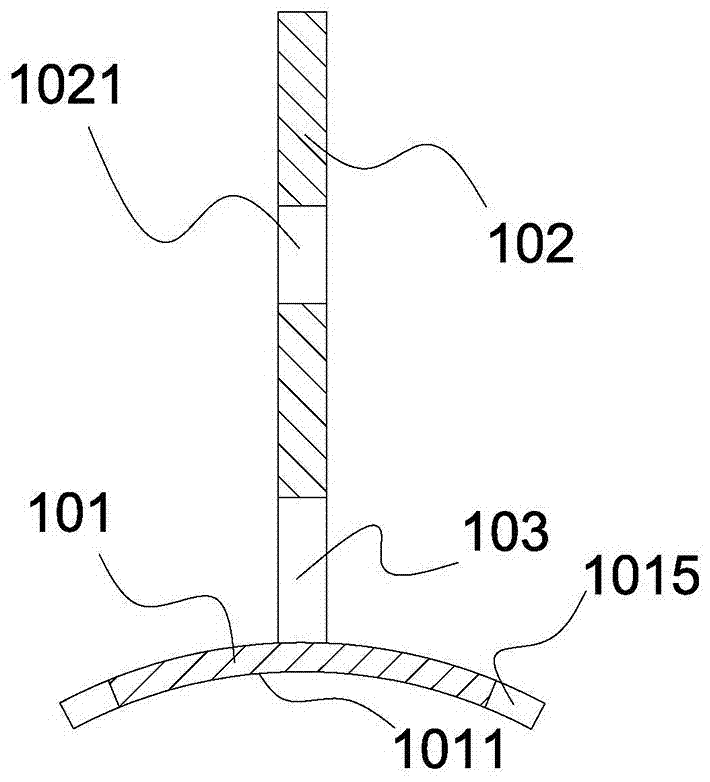

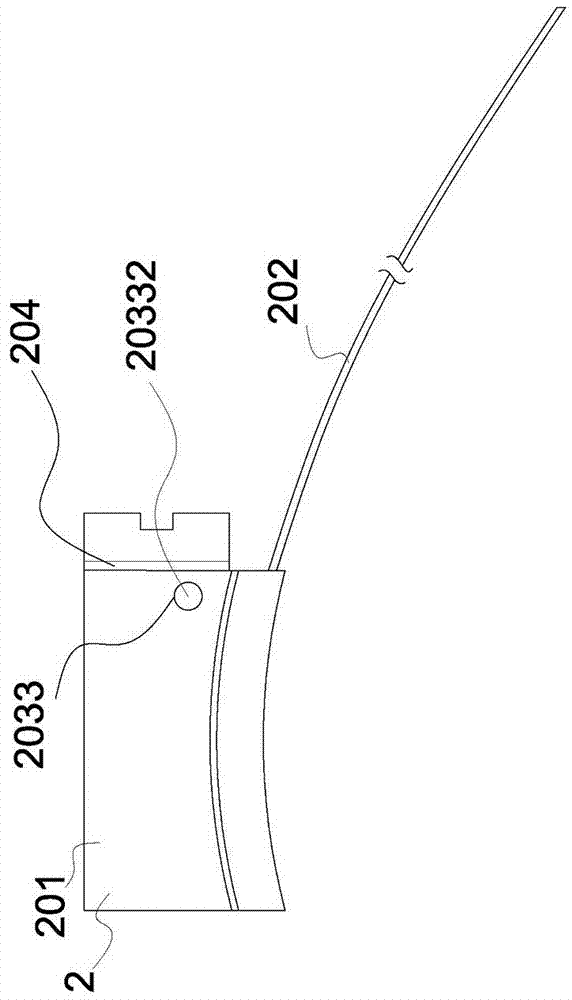

[0029] Example 1: Such as Figure 1-6 As shown, a connecting device for a rod-shaped material includes a connecting seat 1 and a clamping mechanism 2 sleeved on the connecting seat 1 for clamping the rod-shaped material with the connecting seat 1; The mechanism 2 includes an adjusting sleeve 201 and a fastening strap 202. The fixed end 2021 of the fastening strap 202 is fixedly connected to the adjusting sleeve 201, and the other free end 2022 passes through the adjusting sleeve 201. The clamping mechanism 2 also includes a length adjusting component 203 for adjusting the length of the free end 2022 extending out of the adjusting sleeve 201 or entering the length of the adjusting sleeve 201; by wrapping the fastening band 202 around the material, the free end The end 2022 passes through the adjusting sleeve 201, and by adjusting the length adjusting member 203, the fastening strap 202 is tightened to achieve a fastening effect.

[0030] In this embodiment, the length adjusting me...

Embodiment 2

[0036] Example 2: Such as Figure 7-10 As shown, the difference from Embodiment 1 is that the clamping mechanism 2 includes a clamping mechanism provided between the sleeve body 2011 and the adjusting screw 2032 to prevent the adjusting screw 2032 from tightening the fastening belt 202. The radial limit part 204 that rotates radially later, that is, the radial limit part 204 is also provided between the adjusting sleeve 201 and the adjusting screw 2032, so that the material structure is vibrated by a certain external force. Under the circumstances, it can maintain strong stability.

[0037] Further, the radial limiting portion 204 includes a front gasket 2041, a rear gasket 2042 disposed in close contact with the front gasket 2041, and a rear gasket 2042 disposed on the front gasket 2041 and the rear gasket 2041, respectively. The spacer 2042 is closely attached to one side of the trapezoidal bosses 2043 which are evenly distributed and staggered with the axis of the adjusting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com