Method for identifying calibration experiment pseudo-data in mining gas sensor monitoring data

A gas sensor and monitoring data technology, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve problems such as misjudgment of gas concentration in coal mines, achieve the effect of improving the level of automation and solving misjudgment of gas concentration monitoring in coal mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

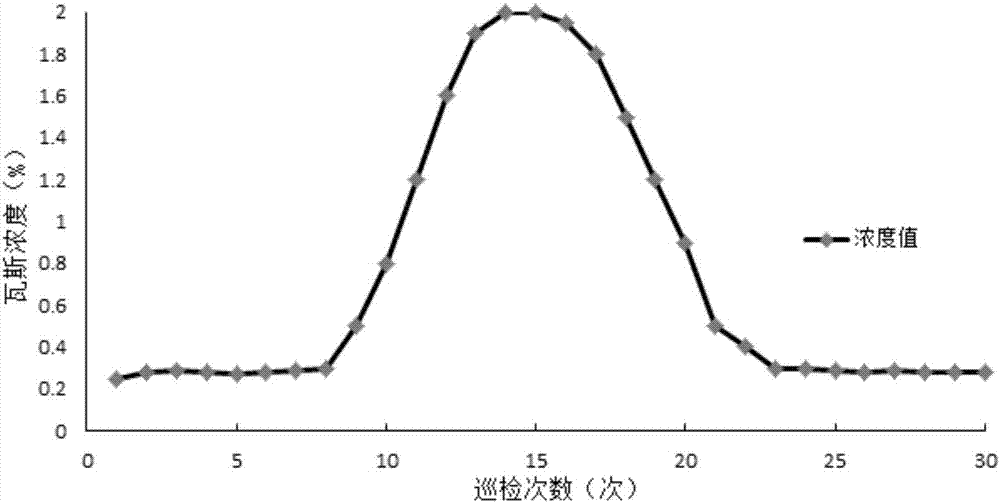

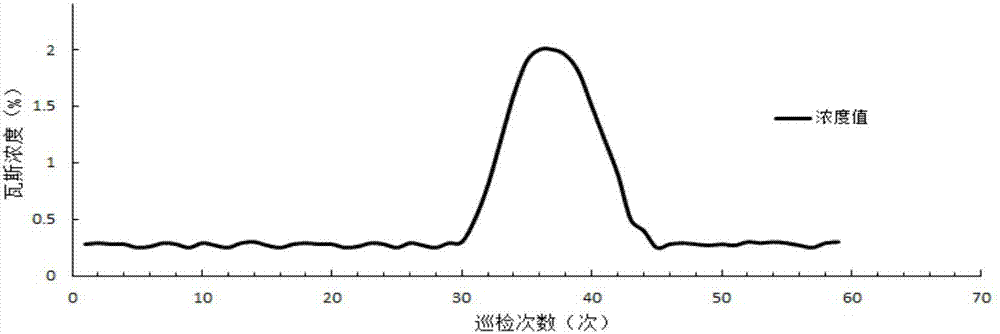

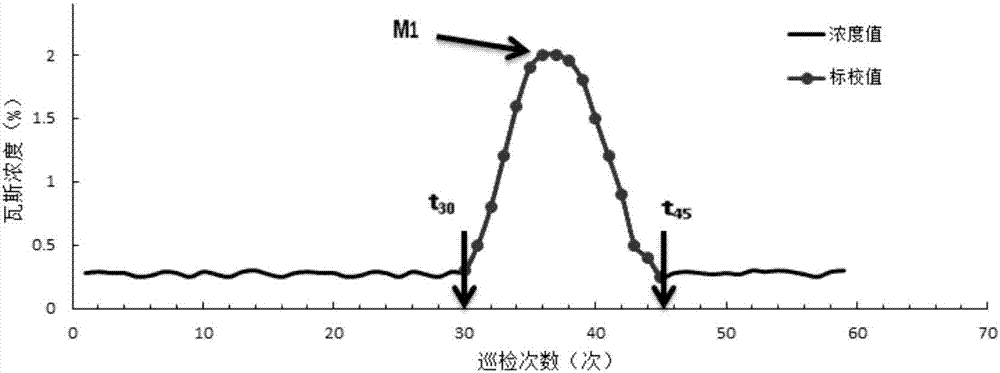

[0022] The method for identifying the false data of the calibration experiment in the monitoring data of the mine gas sensor in this embodiment is implemented by the monitoring background of the existing coal mine safety monitoring system. Real-time monitoring data, and forming the gas concentration data sequence of the gas sensor; the monitoring background adopts the following steps to automatically identify the false data generated by the calibration experiment in the gas concentration data sequence of the gas sensor:

[0023] ①Use formula (1) to judge whether the increase value between the gas concentration values obtained from two adjacent inspections is greater than the set concentration increase judgment threshold Y1, if not, end this identification; if so, enter step ② ;

[0024] C1-C0>Y1 (1)

[0025] In the formula, C1 is the current gas concentration value, and C0 is the previous gas concentration value adjacent to C1; in this embodiment, the concentration increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com