Filter device, hydraulic system and backwashing method

一种过滤设备、反冲洗的技术,应用在化学仪器和方法、过滤分离、膜过滤器等方向,能够解决颗粒污物阻塞、过滤设备性能不利影响、有效过滤元件面积的大小不能明显减小等问题,达到节约空间、长使用寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

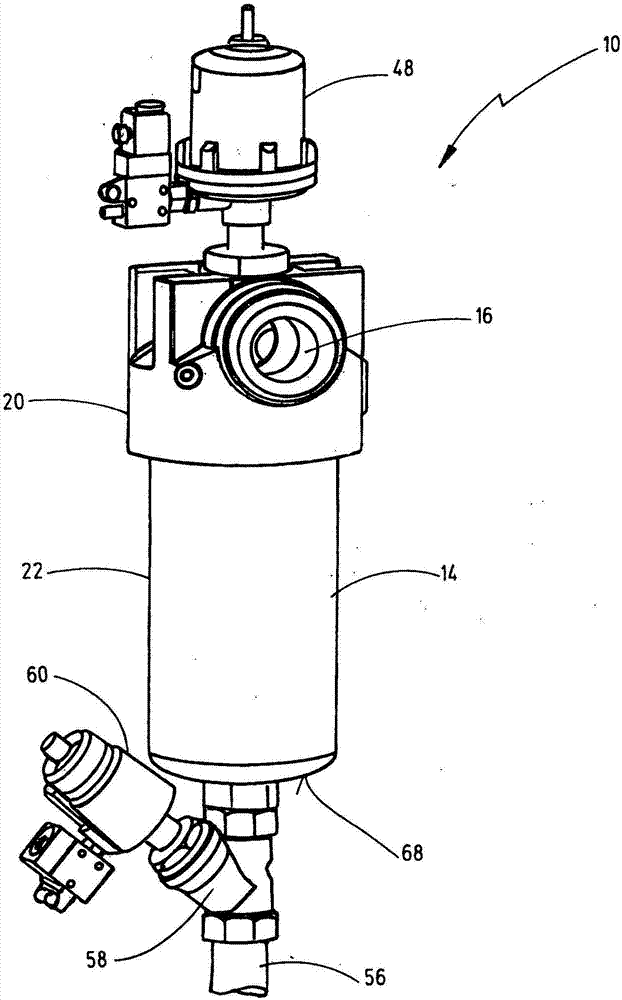

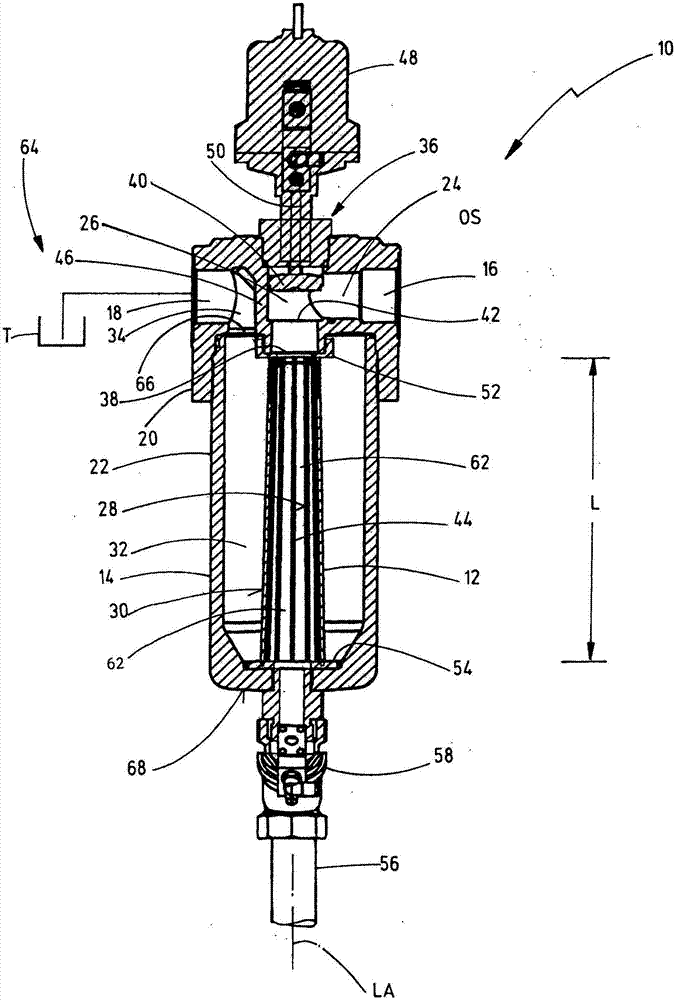

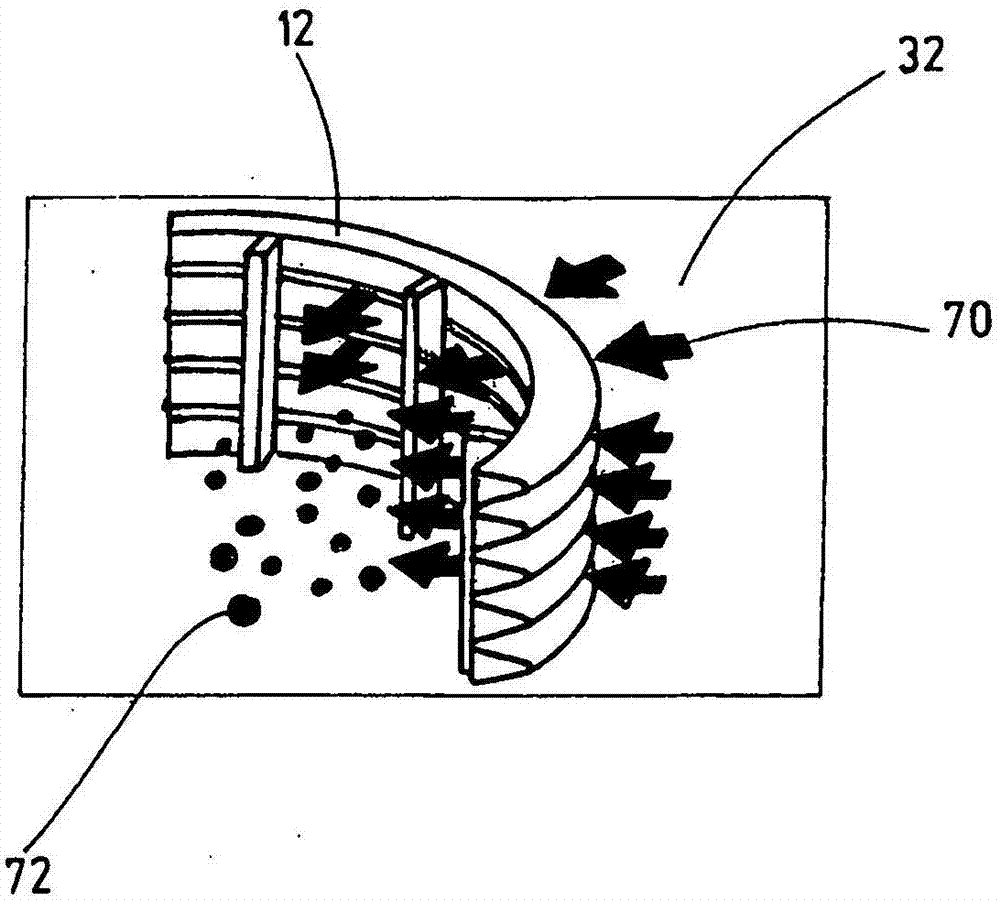

[0033] exist figure 1 and 2 shows a filter device 10 according to the invention, which has a filter element 12 . The filter element 12 is accommodated in a filter housing 14 which has fluid connections 16 , 18 for the raw liquid or filtrate. The fluid connections 16 , 18 are connected to one another via the filter element 12 in a fluid-conducting manner. The filter housing 14 includes a head part 20 and a pot-shaped receiving part 22 . In this case, the head piece 20 has fluid connections 16 , 18 for unfiltrate and filtrate. The unfiltrate is guided from the fluid connection 16 for the unfiltrate along a first fluid-conducting path 24 in the direction of the interior of the filter element 12 . In this case, the first fluid-conducting path 24 runs at right angles to the deflection 26 . During filter operation, the fluid then flows through the filter element 12 from the inside to the outside, with dirt, in particular particles, accumulating on the inner side 28 of the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com