Forming Cutting Tools

A technology for forming cutting and tooling, which is applied in the direction of manufacturing tools, turning equipment, metal processing equipment, etc., can solve the problems of decreased work efficiency, damaged cylindrical part 8, difficult to discharge, etc., and achieves the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

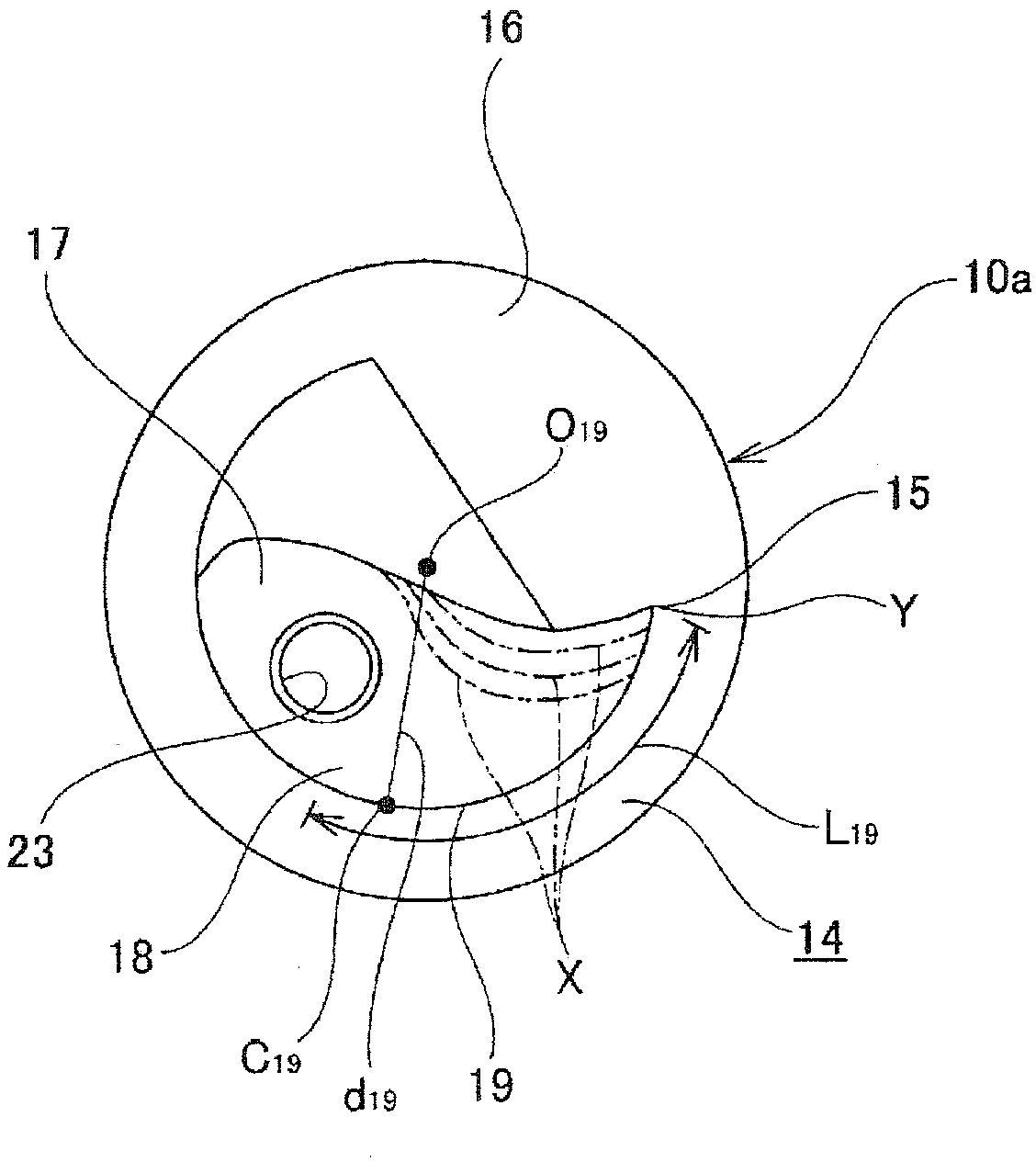

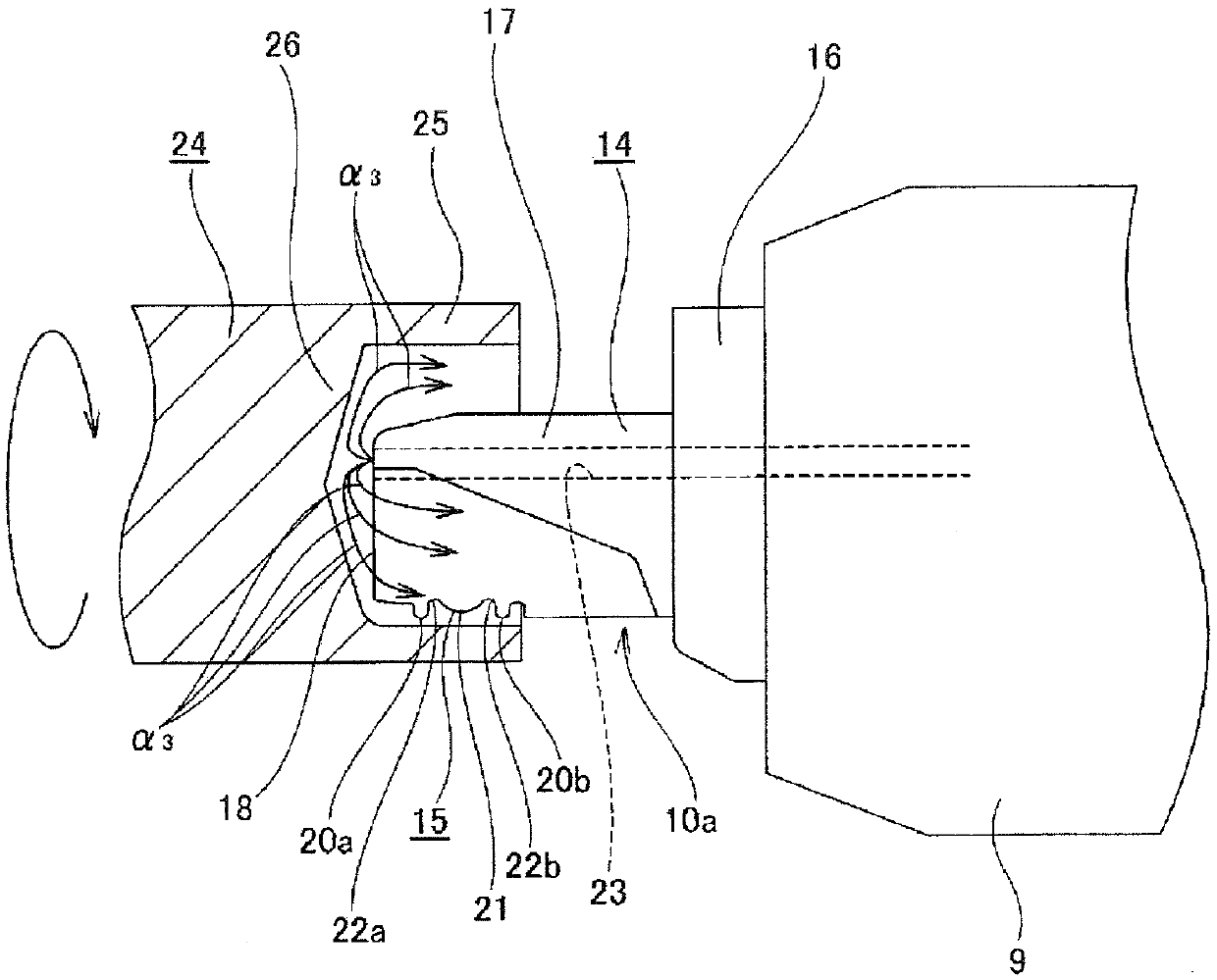

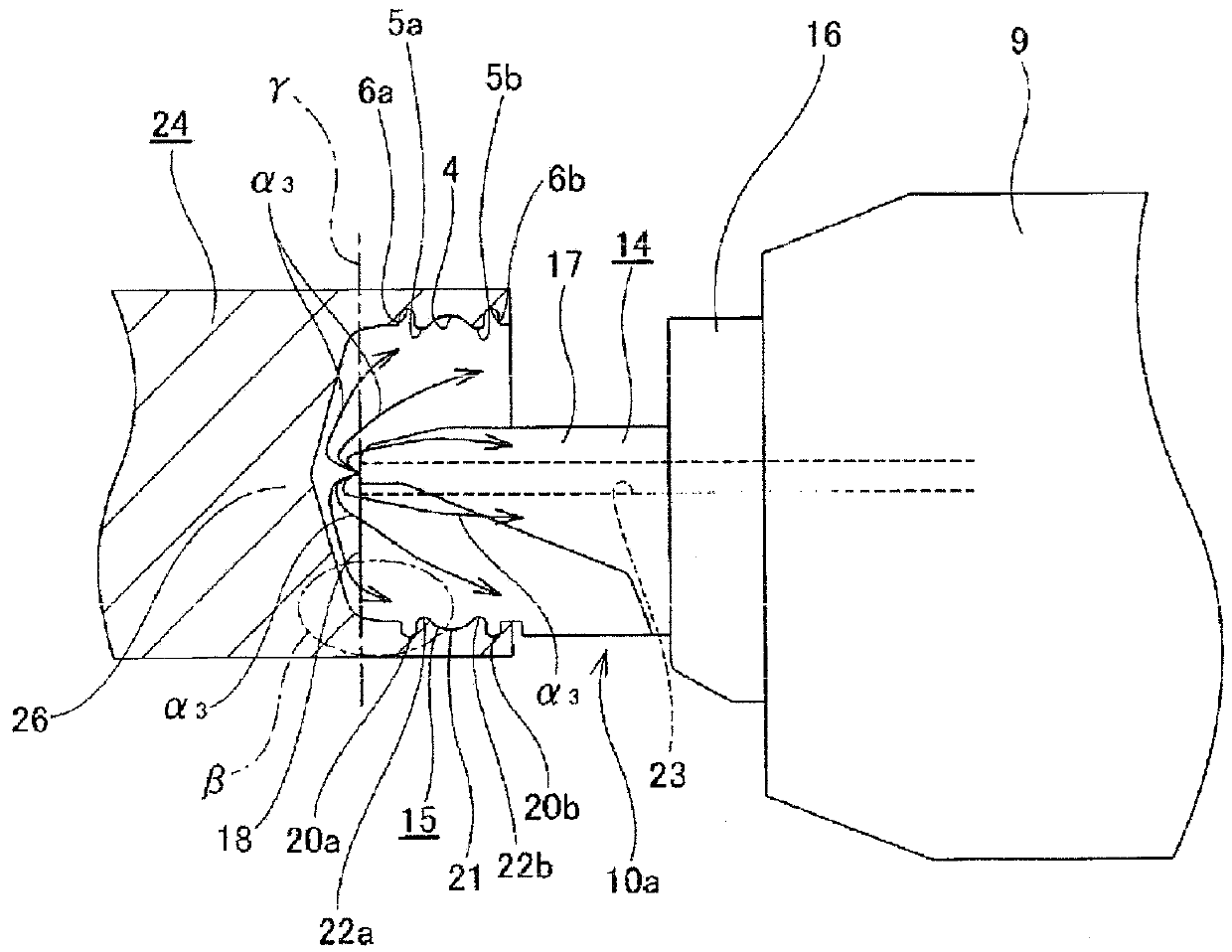

[0075] [the first example of embodiment]

[0076] use figure 1 , 2 to describe the first example of the embodiment of the present invention. The shaped cutting tool 10a of this example is used for cutting to process the inner peripheral surface of the annular portion of the workpiece into a desired shape. Specifically, in for example constituting Figure 8 The inner peripheral surface of the outer ring 2 of the shown ball bearing 1 is used for cutting to form the outer ring raceway 4, a pair of shoulders 5a, 5b, and a pair of seal locking grooves 6a, 6b. Next, the structure of the shaped cutting tool 10a of this example will be described, and then a cutting method of assembling the shaped cutting tool 10a of this example in a machine tool (for example, a lathe, etc.) will be described.

[0077] The forming cutting tool 10a of this example is made of, for example, high-speed steel (SKH51, high-speed steel), cemented carbide, etc., and is used for cutting to form the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com