Blowing head, method for producing a blown film and blown film installation

A technology of blow molding die head and equipment, which is applied in blown film equipment and the field of making blown film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

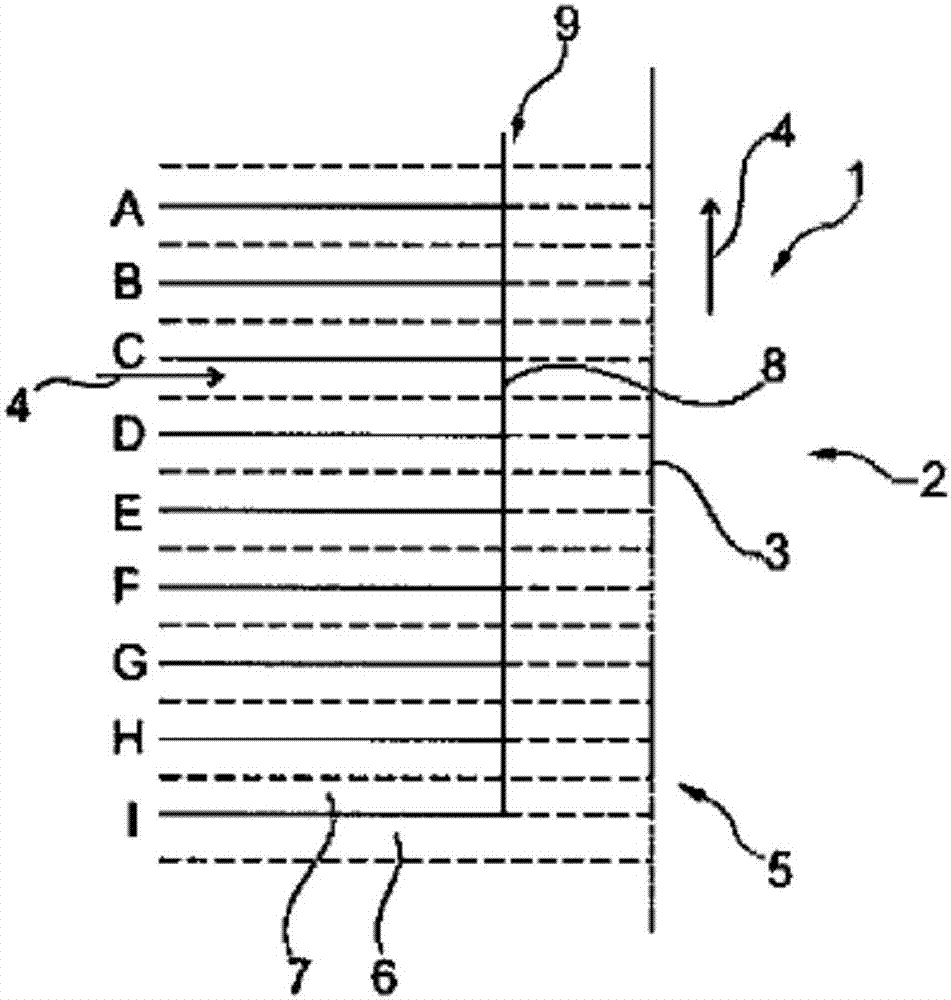

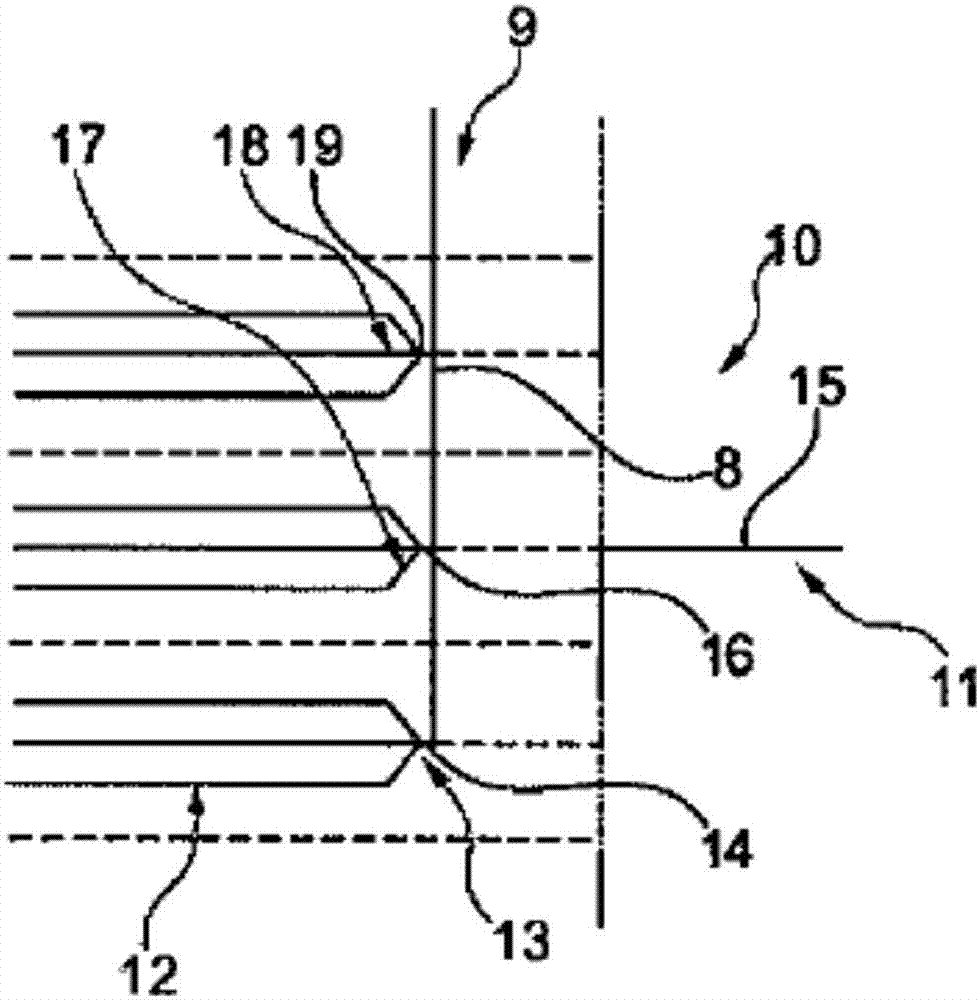

[0057] Compared to other types, figure 1 The blow molding die (1) in (only partly shown) comprises a plate-type screw distributor (2) with an extrusion axis (3). Nine helices (A, B, C, D, E, F, G, H, J) are sequentially arranged on mutually parallel layers along the extrusion direction (4), and each helix is formed on two stacked plates (6 , 7) between plate packages (5) (exemplary numbers).

[0058] These spirals extend radially inward until the extrusion axis (3) enters the annular gap (8) leading to the pipe die (9).

[0059] During operation of the blow molding die (1), the melt stream produced by the extruder (not shown) is directed into nine spirals, where they are directed towards the annular gap ( 8) Flow. In this way, nine layers of membrane are produced in the annular gap (8). Starting from the input of the bottom screw (J) into the annular gap (8), a monolayer melt flow is generated that rises through the annular gap (8) in the extrusion direction (4). When rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com