A Finite Element Modeling Method for Particle Reinforced Composite Materials Based on Pixel Theory

A composite material and particle enhancement technology, applied in image enhancement, 3D modeling, image data processing, etc., can solve the problems of not accurately reflecting the real microstructure of materials, complex operations, low efficiency, etc., to solve engineering problems in the field, Effects of Improving Simulation Accuracy and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

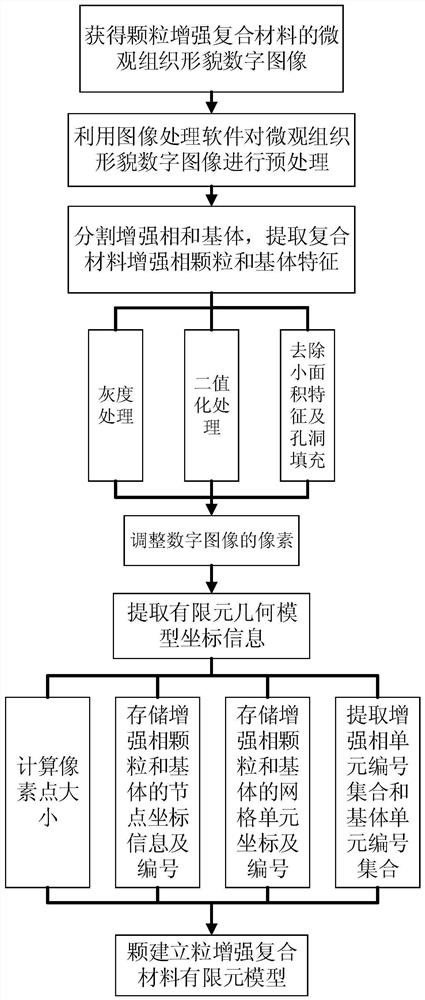

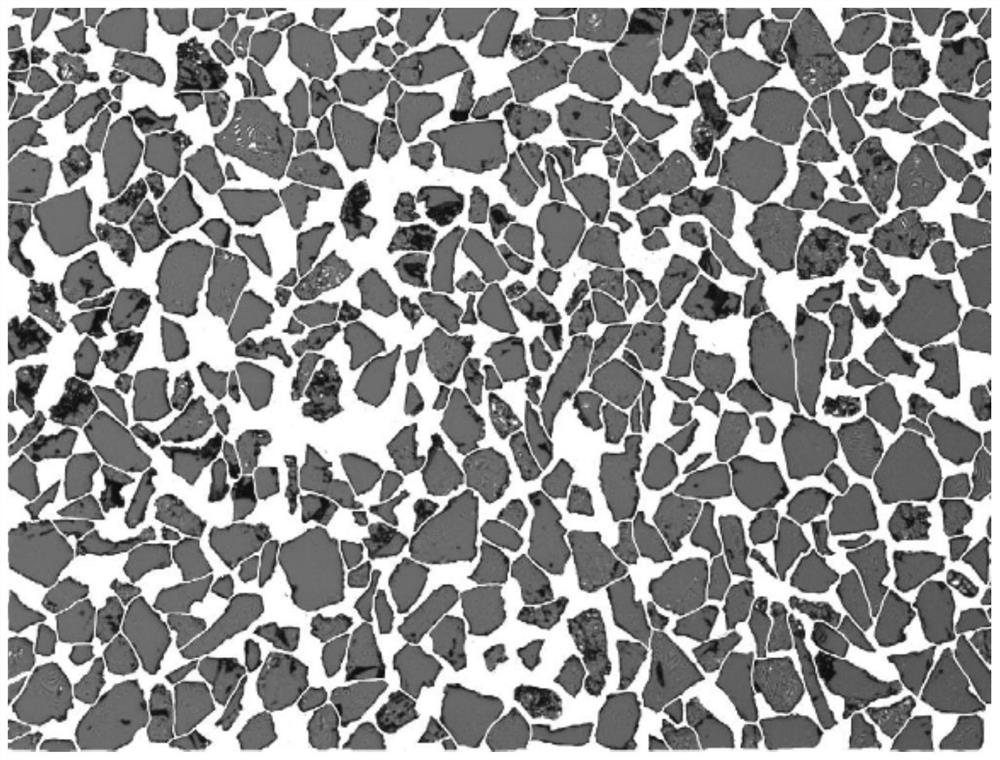

[0077] A finite element modeling method for particle reinforced composite materials based on the pixel theory disclosed in this embodiment, the specific implementation steps are as follows:

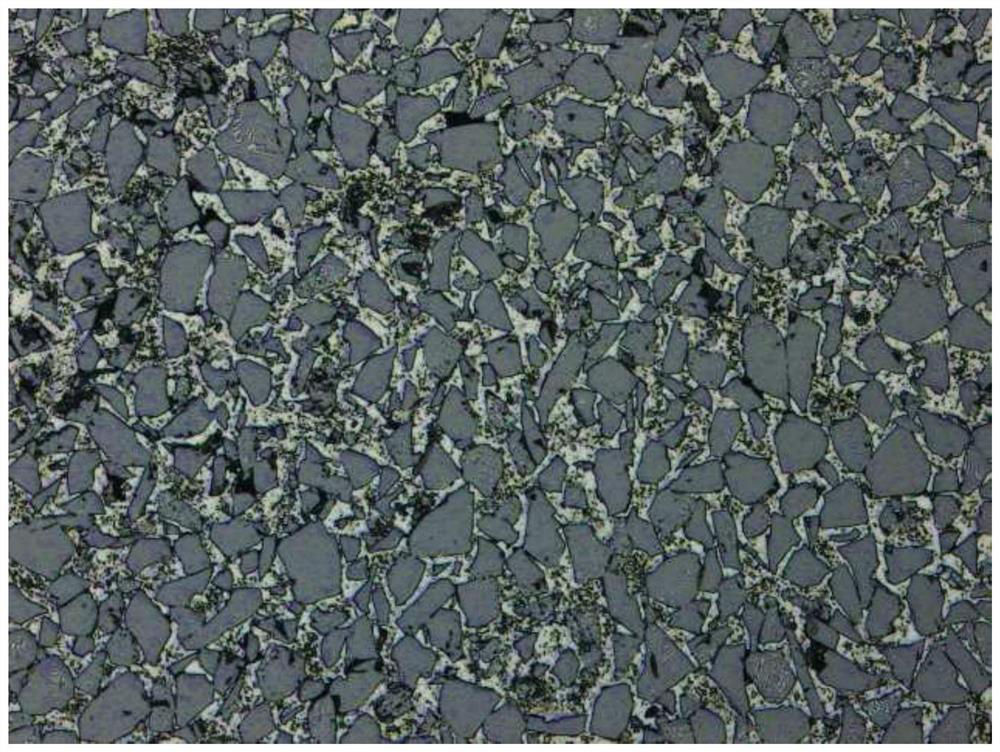

[0078] Step 1. Use SEM, OM and other methods to observe and extract the specific microstructure image of the particle-reinforced composite material, and save it in JPEG format for subsequent digital image processing.

[0079] According to the specific material used, it is processed by wire cutting, grinding, polishing, ultrasonic vibration cleaning and other processes to obtain a smooth and clean material section to ensure that the oxidation and corrosion areas on the surface of the material are removed cleanly. Using SEM scanning electron microscope and OM optical microscope Observe the specific microstructure of the material, select the typical area with the least stains and scratches, and the clearest microstructure of the material, and save the specific microstructure photos of the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com