Nuts for fastening to panels

A technology of nuts and plates, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of high assembly consumption and achieve good composite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

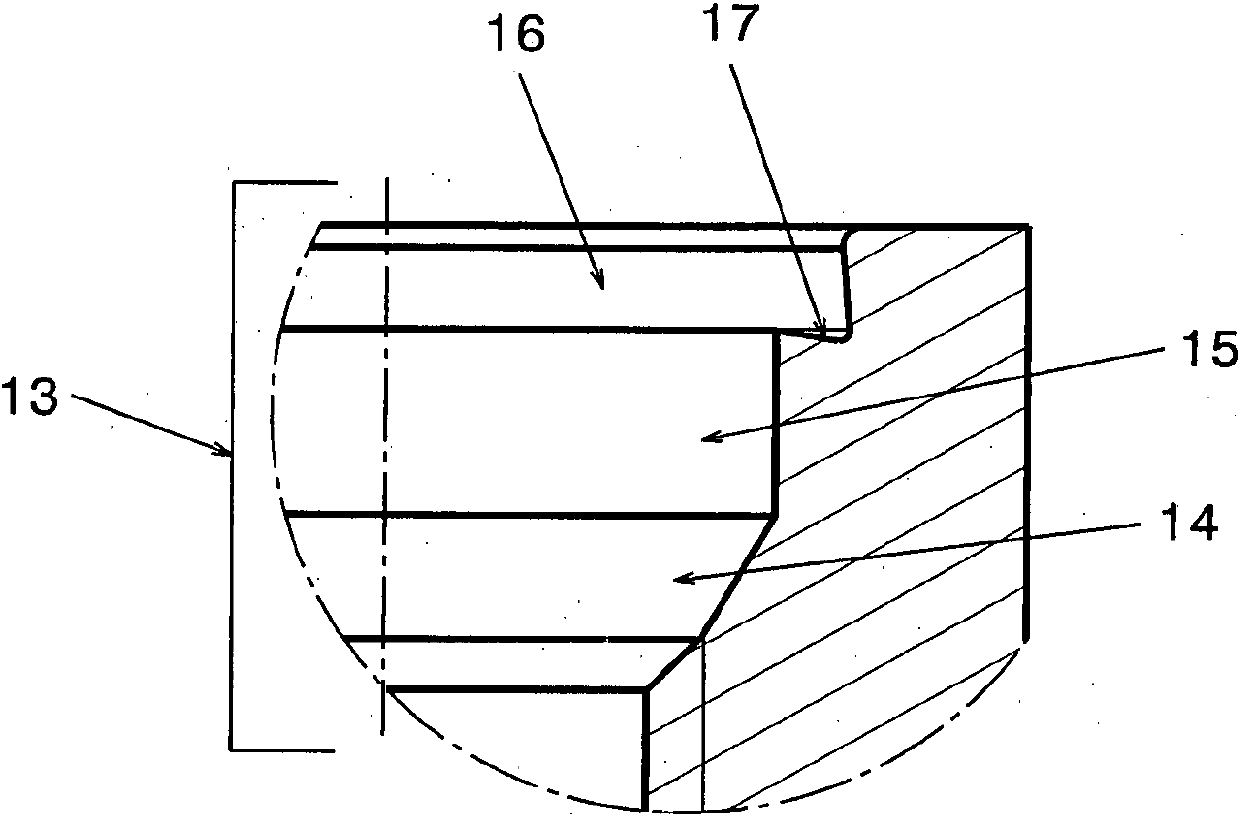

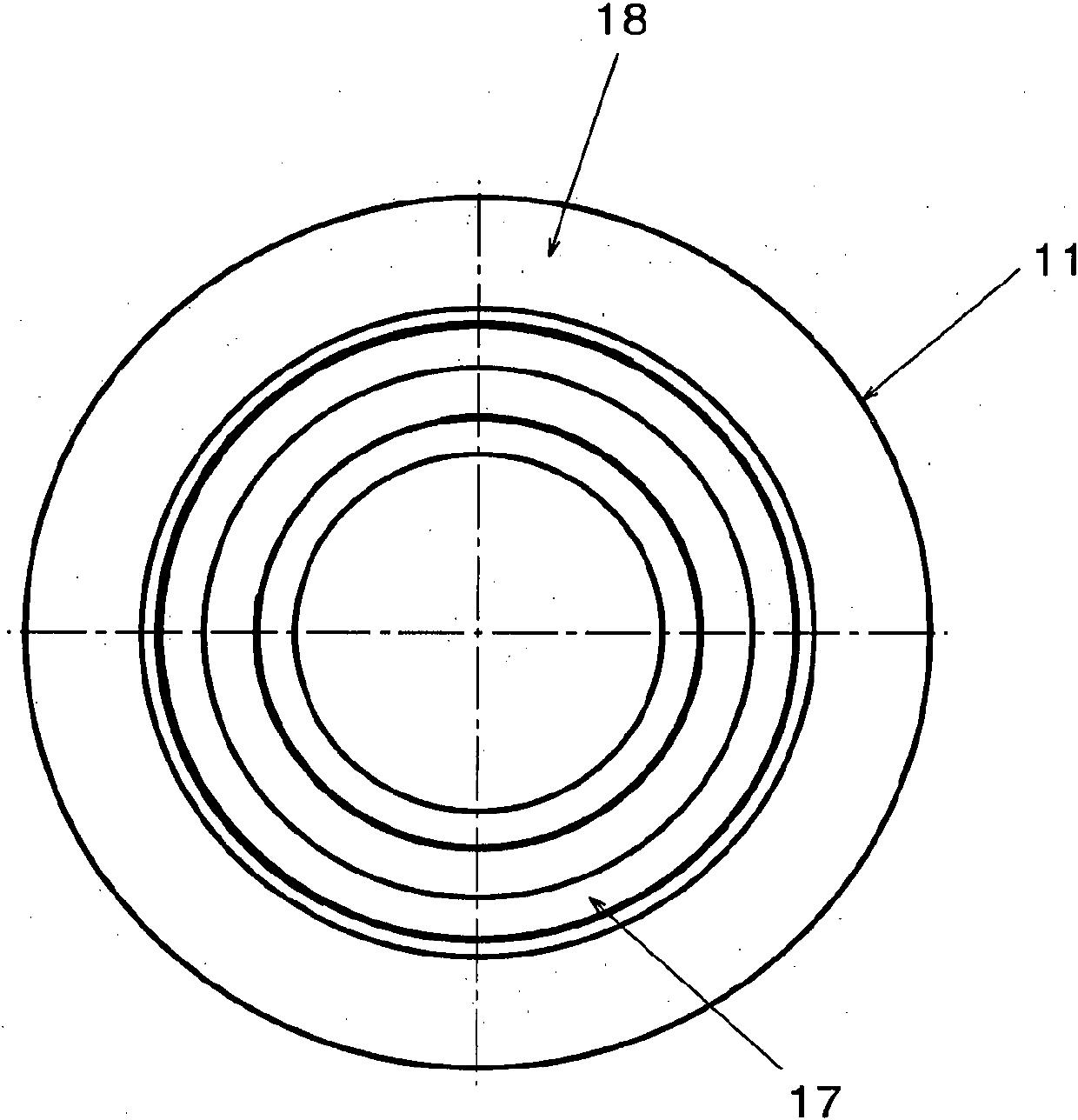

[0029]The nut 1 selected as the exemplary embodiment consists essentially of a hollow cylindrical nut body 11 with an internal thread 12 . The outer contour of the nut 1 corresponds to conventional contours known in the prior art for a properly positioned insertion. A fastening contour 13 formed by an embedding adjoins the internal thread 12 . The fastening contour 13 comprises a conically enlarged centering section 14 , to which a cylindrically configured outlet section 15 adjoins, which transitions into a likewise cylindrically configured extrusion section 16 with enlarged diameter. middle. A radially outwardly inclined shoulder 17 is formed between the discharge section 15 and the pressing section 16 , so that a conical inwardly tapering ring profile is formed. In the exemplary embodiment, the outlet section 15 is provided with reinforcements (not shown). Furthermore, in the exemplary embodiment, the nut body 11 is provided with a non-illustrated stop toothing on its abu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com