Method for producing electric motor and electric motor

A technology for electric motors and coil layers, which is applied in the field of manufacturing electric motors and can solve problems such as the difficulty of temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

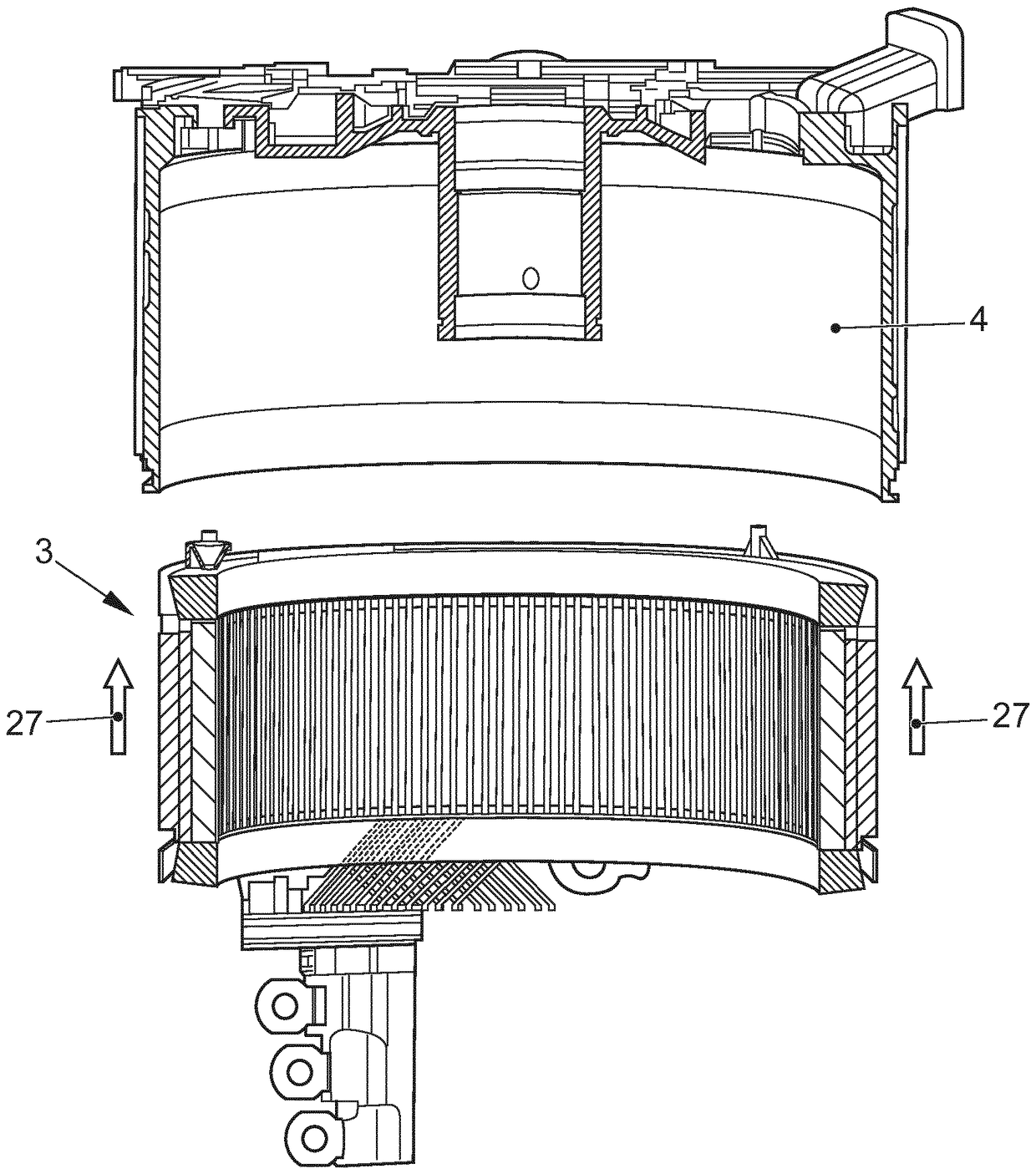

[0036] figure 1 The electric motor 1 according to the invention which is configured as a drive motor for a motor vehicle is shown in a cutaway view. The electric motor 1 has a rotor 2, a stator 3, and a housing member 4 that surrounds the stator 3 and is configured as a cooling unit.

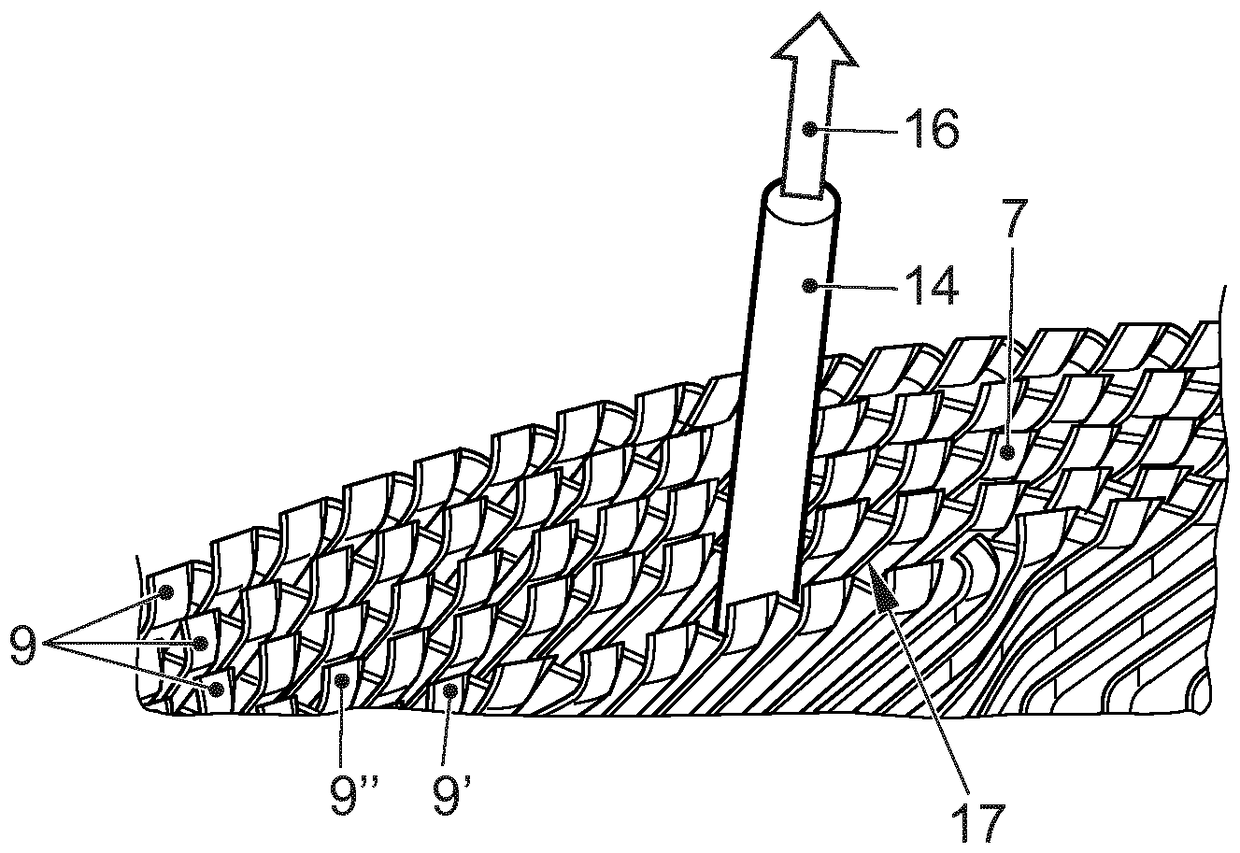

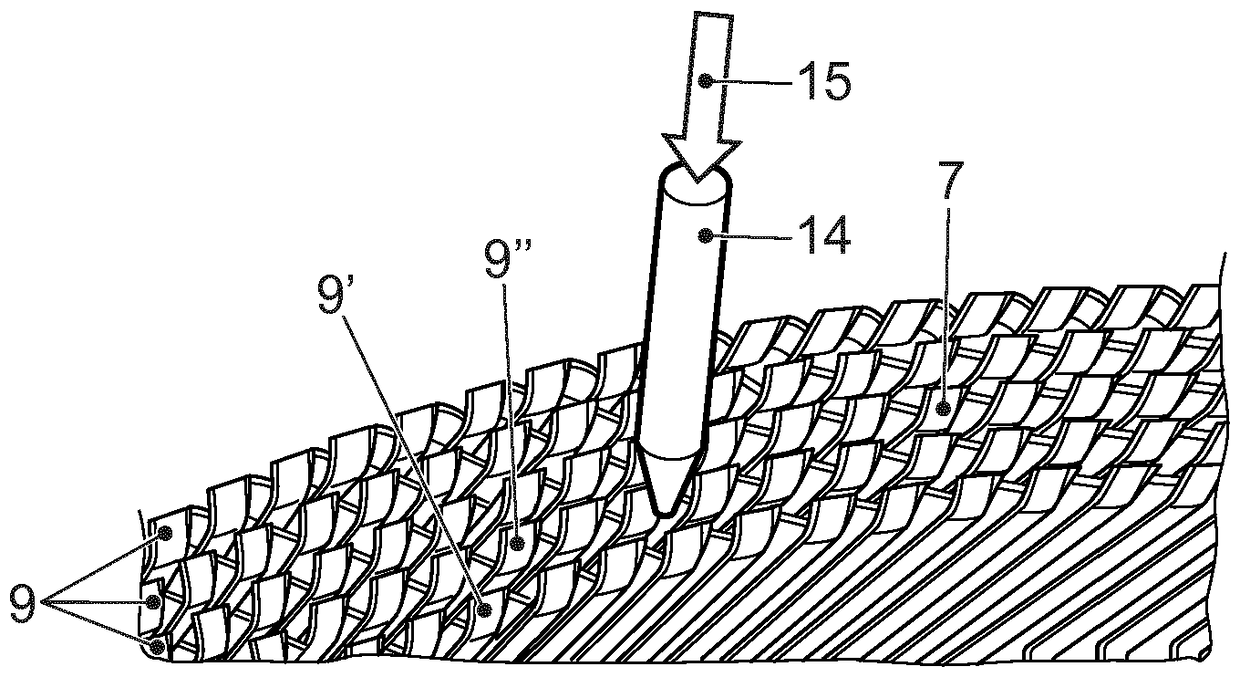

[0037] The stator 3 includes a hollow cylindrical stator plate 5 composed of a laminated group (or plate group, namely Blechpaket), and a structure composed of a plurality of wires with a winding head 7 protruding axially from the stator plate 5 as The distributed winding 6 of the wave winding and the insulating disc 8. The distributed windings 6 are arranged in slots of the stator plate 5 extending radially inward.

[0038] As shown in magnification from figure 1 The details of X figure 2 As can be seen from this, the distributed winding 6 or winding head 7 configured as a wave winding is composed of a plurality of surrounding annular coil layers 9, 9', 9" arranged one on top of the other. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com