Method for manufacturing an electric motor and electric motor

一种电动机、线圈层的技术,应用在制造电动机领域,能够解决温度传感器不可容易等问题,达到避免测量值偏差、避免误差影响的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] figure 1 The electric motor 1 according to the invention, which is designed as a drive motor for a motor vehicle, is shown in section. The electric motor 1 has a rotor 2 , a stator 3 and a housing component 4 which surrounds the stator 3 and is designed as a cooling unit.

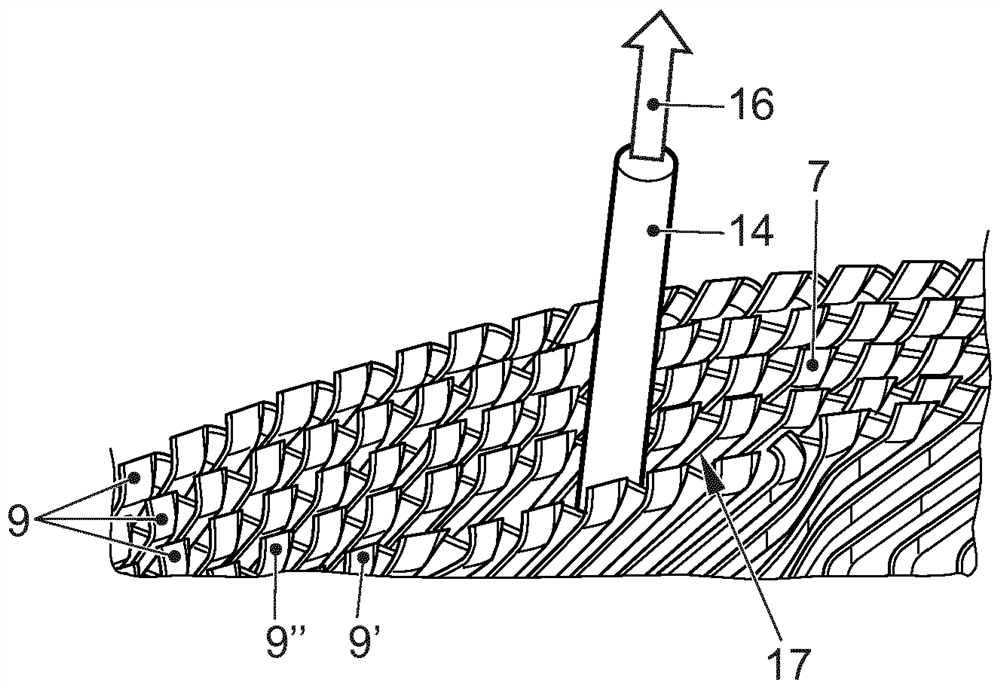

[0037] The stator 3 comprises a hollow cylindrical stator plate 5 consisting of a stack of laminations (or a stack of plates, ie Blechpaket), a structure consisting of a plurality of wires with a winding head 7 protruding axially from the stator plate 5 as The distributed winding 6 of the wave winding and the insulating disk 8 . Distributed windings 6 are arranged in radially inwardly extending slots of stator plate 5 .

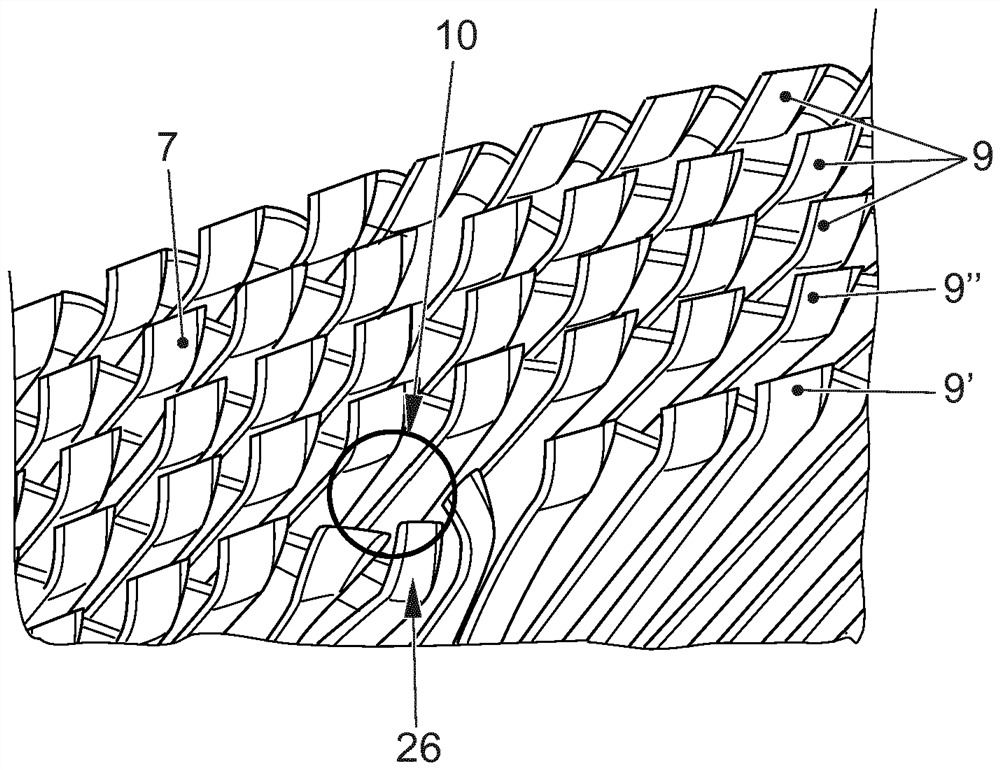

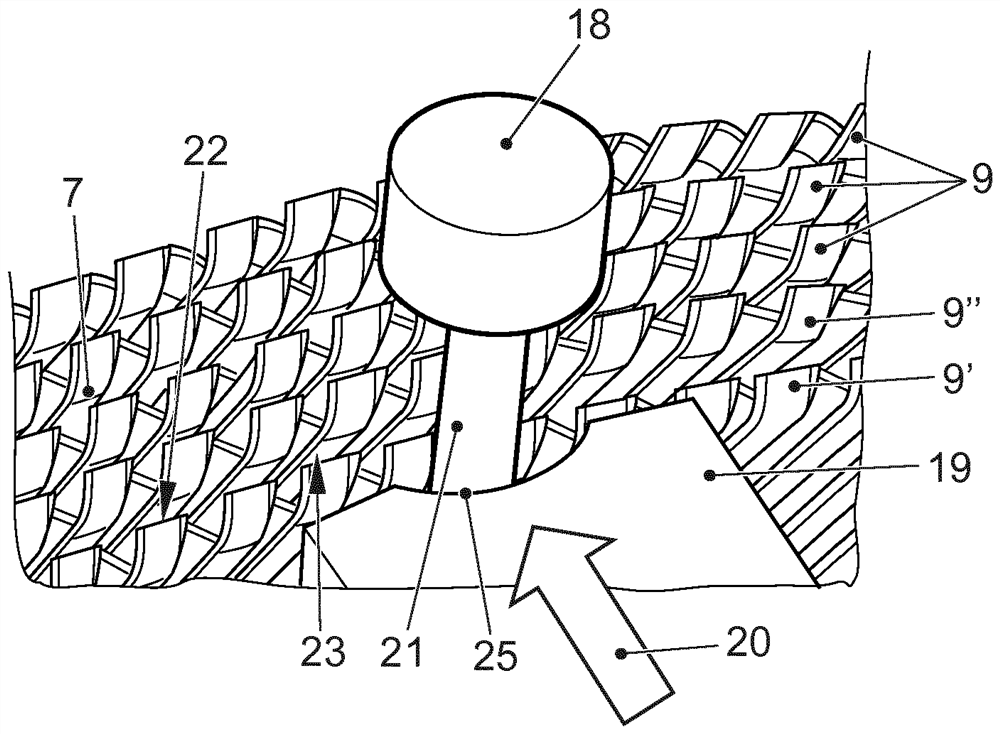

[0038] as presented zoomed in from figure 1 Details of X's figure 2 As can be seen in , the distributed winding 6 or winding head 7 configured as a wave winding is formed from a plurality of surrounding annular coil layers 9 , 9 ′, 9 ″ arranged one above the other. In the case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com