Zucchini seed harvester

A technology for zucchini seeds and fixing zucchini is applied in the directions of threshing equipment, applications, agricultural machinery and implements, which can solve the problems of insecurity, labor and labor, and achieve the effects of low cost and simple production materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

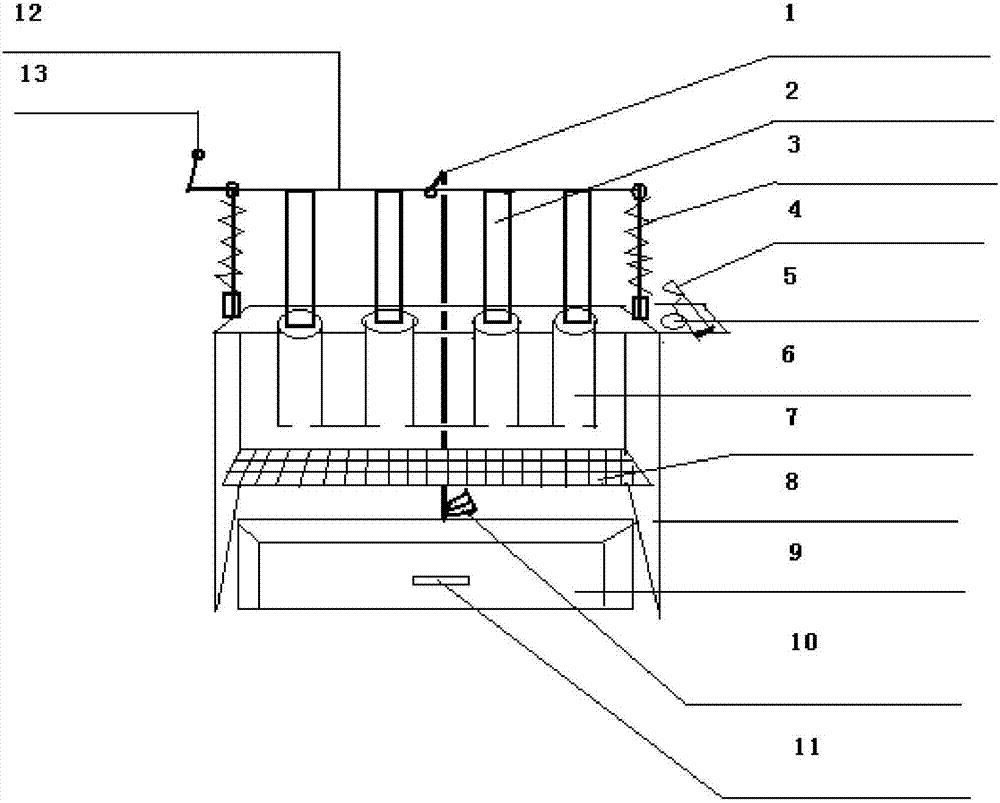

[0013] When using the above-mentioned zucchini seed harvester, the upper and lower tops of the zucchini are first cut off with a top cutter. Then turn the steering handle of the tamper, remove the tamper, put the top-cut zucchini into the fixed cylinder, then turn the steering handle of the tamper to align it with the fixed cylinder, step on the stamping plate with your feet, and the tamper moves downward to enter the fixed cylinder. Squeeze the central part of the zucchini, squeeze the zucchini seeds onto the sieve bed, and then knead them so that the zucchini seeds pass through the mesh of the sieve and enter the storage box below. Complete a seeding event. Two people cooperate to be more efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com