Purifier electric field structure and purifier

A purifier and electric field technology, applied in the field of purifiers, can solve the problems of poor plate-type electric field charging effect, inconvenient installation and maintenance, low effective pass rate, etc., to reduce cleaning frequency, simple production and increase charging time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

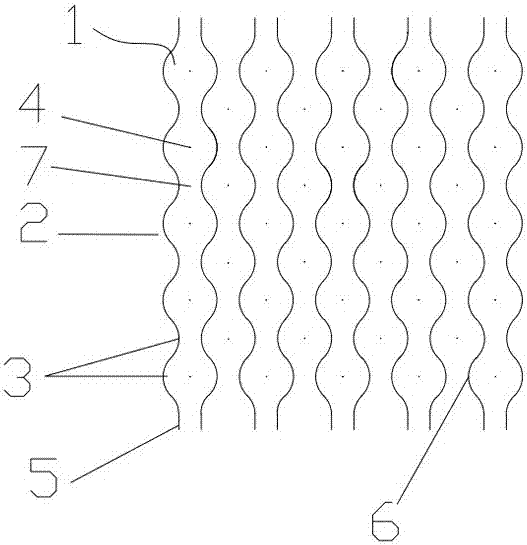

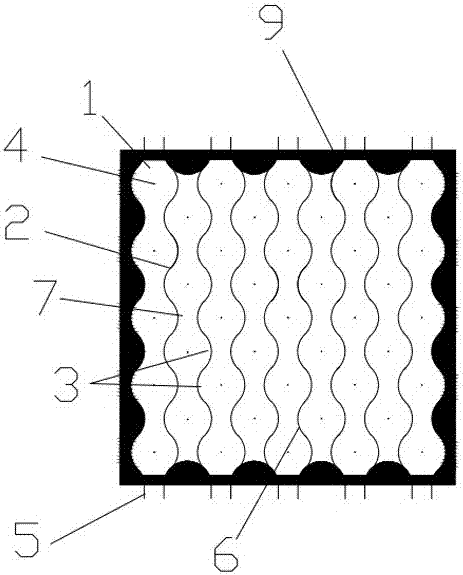

[0047] exist figure 1 , figure 2 In the described embodiment, a purifier electric field structure includes:

[0048] A number of evenly distributed dust-collecting pole units 1; the dust-collecting pole unit 1 is surrounded by a number of uniformly arranged dust-collecting plates 2; the dust-collecting plate 2 is a wave-shaped plate; the two board surfaces of the dust-collecting plate 2 are A number of dust-collecting pole enclosure grooves 3 are provided, and the dust-collection pole enclosure grooves 3 on the two board surfaces are alternately arranged; the dust-collection pole enclosure grooves 3 are arc-shaped grooves; The dust collecting pole enclosing groove 3 is respectively surrounded with the dust collecting pole enclosing groove 3 on the adjacent dust collecting plate 2 to form the dust collecting pole unit 1; the dust collecting pole enclosing groove 3 is on the other surface of the dust collecting plate 2 Wave bulges 6 are formed, and the wave bulges 6 on two ad...

Embodiment 2

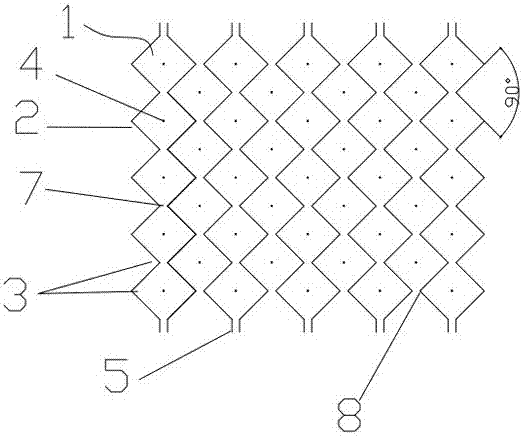

[0056] exist image 3 , Figure 4 In the described embodiment, a purifier electric field structure includes:

[0057] A number of evenly distributed dust-collecting pole units 1; the dust-collecting pole unit 1 is surrounded by a number of uniformly arranged dust-collecting plates 2; the two board surfaces of the dust-collecting plate 2 are respectively provided with a number of dust-collecting pole enclosing grooves 3 , and the dust-collecting pole enclosure grooves 3 on the two board surfaces are staggered; the dust-collecting plate 2 is a zigzag plate; the dust-collecting pole enclosure groove 3 is a triangular groove; The bending angle of the plate is 90 degrees, that is, the included angle of the 3 triangles surrounding the dust collecting pole is 90 degrees. The dust collecting pole enclosing grooves 3 on the two board surfaces of the dust collecting plate 2 are respectively enclosed with the dust collecting pole enclosing grooves 3 on the adjacent dust collecting plat...

Embodiment 3

[0065] exist Figure 5 , Image 6 In the described embodiment, in figure 1 , figure 2 In the described embodiment, a purifier electric field structure includes:

[0066] A number of evenly distributed dust-collecting pole units 1; the dust-collecting pole unit 1 is surrounded by a number of uniformly arranged dust-collecting plates 2; the two board surfaces of the dust-collecting plate 2 are respectively provided with a number of dust-collecting pole enclosing grooves 3 , and the dust-collecting pole enclosure grooves 3 on the two board surfaces are staggered; the dust-collecting plate 2 is a zigzag plate; the dust-collecting pole enclosure groove 3 is a triangular groove; The bending angle of the plate is 120 degrees, that is, the included angle of the 3 triangles surrounding the dust collecting pole is 120 degrees. The dust collecting pole enclosing grooves 3 on the two board surfaces of the dust collecting plate 2 are respectively enclosed with the dust collecting pole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap