Gradient elastic non-pneumatic tire

A technology of non-pneumatic tires and elastic wheels, which is applied in the direction of non-pneumatic tires, tire parts, transportation and packaging, etc., which can solve the problems of inability to deal with the stress concentration of wheels and unfavorable tire gripping ability, and achieve excellent gripping ability and grounding Long footprint and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

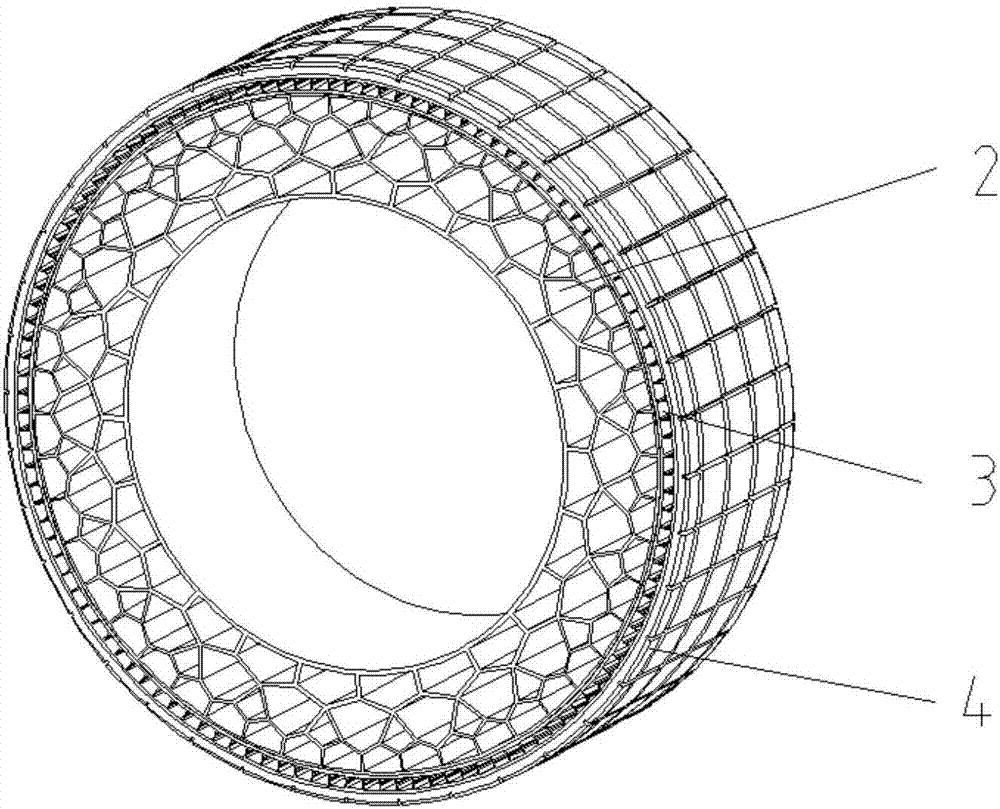

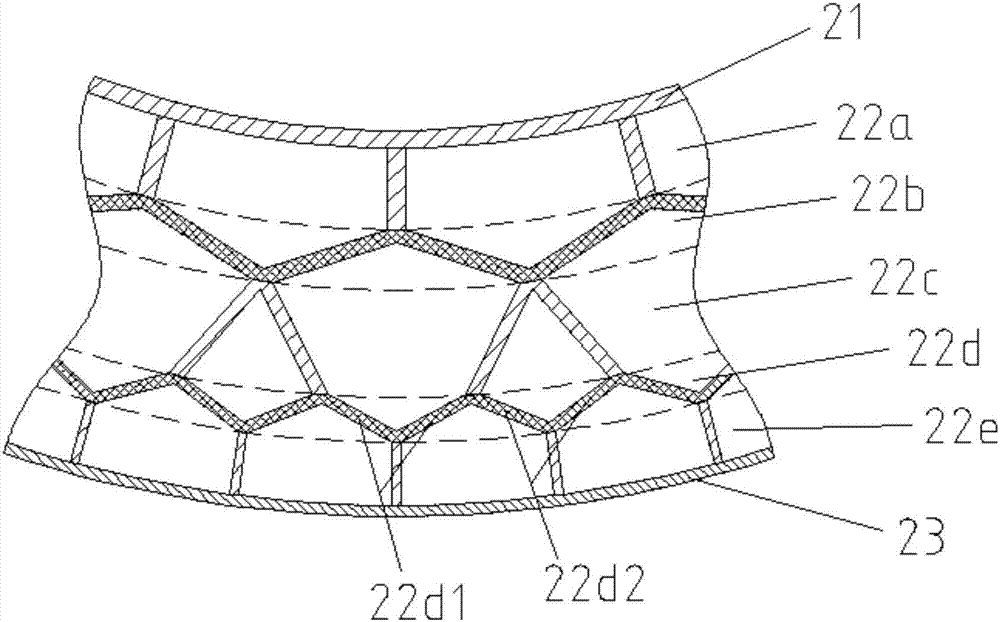

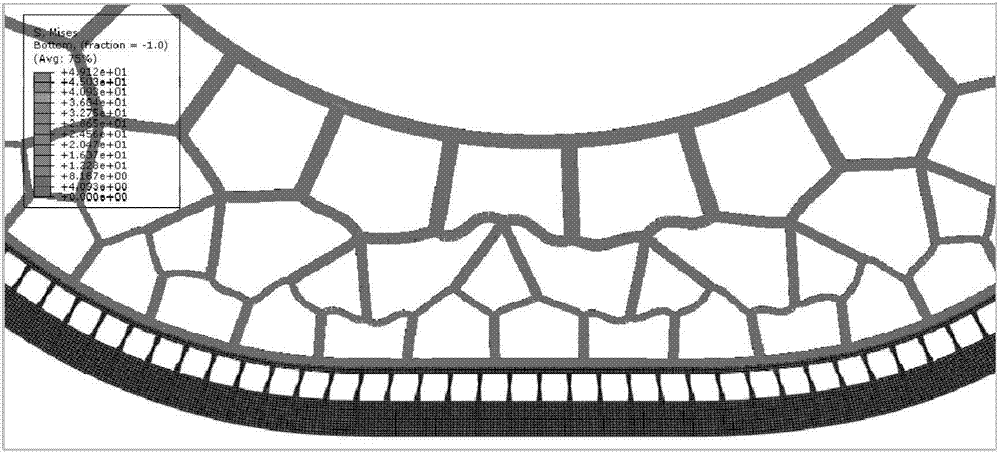

[0030] Such as figure 1 As shown, a gradient elastic non-pneumatic tire includes a support structure 2 and an annular belt 3; the surface of the annular belt 3 is fixed with a tread 4; the annular belt 3 is surrounded by a square grid; Around the configuration, the annular belt 3 can be integrally formed by casting or 3D printing. The support structure 2 includes an inner fixing ring 21, gradient elastic spokes 22 and an outer fixing ring 23, the inner fixing ring 21 is installed on the outer side of the wheel rim, the outer fixing ring 23 is installed on the inner side of the annular belt 3, and the gradient elastic The spoke 22 is between the inner fixed ring 21 and the outer fixed ring 23; the gradient elastic spoke (22) comprises a rigid layer and a flexible layer, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap