Blast-furnace burden distribution method for high-proportion pellets

A high-proportion, material-distributing technology, applied in the field of blast furnace material distribution with high-proportion pellets, can solve the problems of blast furnace irregularity, increased pellet ratio, and difficulty in precise material distribution, so as to ensure stable and smooth operation, strong operability, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

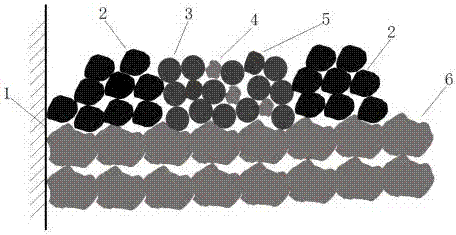

[0019] Embodiment 1: The blast furnace material distribution method of the high-proportion pellets adopts the following specific process.

[0020] Blast furnace effective volume 1000m 3 , the proportion of pellets is 30%, the proportion of sinter, lump ore, limestone, steel slag, etc. is 70%, and the coke ratio is 20kg / t-Fe; the distribution matrix is shown in Table 1.

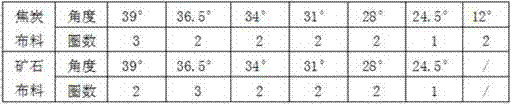

[0021] Table 1: Cloth matrix of Example 1

[0022]

[0023] Among them, in the ore distribution matrix, the 3 circles of the 39° distribution gear and the 2 circles of the 30° distribution gear are all sintered ore, and the middle gears are pellets and the remaining sinter, lump ore, limestone, steel slag, etc. All coke is mixed with pellets. During the smelting process, the blast furnace runs smoothly.

Embodiment 2

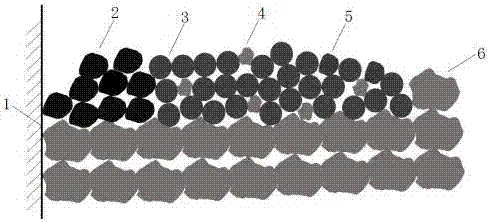

[0024] Embodiment 2: The method for distributing material for the blast furnace with high proportion pellets adopts the following specific process.

[0025] Blast furnace effective volume 1000m 3 , the ratio of pellets is 50%, the ratio of sinter, lump ore, limestone, steel slag, etc. is 50%, and the coke ratio is 30kg / t-Fe; the distribution matrix is shown in Table 2.

[0026] Table 2: the cloth matrix of embodiment 2

[0027]

[0028] Among them, in the ore distribution matrix, the 3 circles of the 39° distribution gear and the 2 circles of the 28° distribution gear are all sintered ore, and the middle gears are pellets and the remaining sinter, lump ore, limestone, steel slag, etc. All coke is mixed with pellets. During the smelting process, the blast furnace runs smoothly.

Embodiment 3

[0029] Embodiment 3: The method of distributing material for the blast furnace with high proportion pellets adopts the following specific process.

[0030] Blast furnace effective volume 1000m 3 , the ratio of pellets is 80%, the ratio of sinter, lump ore, limestone, steel slag, etc. is 20%, and the coke ratio is 40kg / t-Fe; the distribution matrix is shown in Table 3.

[0031] Table 3: The cloth matrix of embodiment 3

[0032]

[0033] Among them, in the ore distribution matrix, the 2 circles of the 39° distribution stalls are all sintered ore, and the other distribution stalls are pellets and the remaining sinter, lump ore, limestone, steel slag, etc. All coke is mixed with pellets. During the smelting process, the blast furnace runs smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com