Full-section aerated hydraulic facility with pressure inlet of a multi-hole open channel

A porous, full-section technology, applied in the field of aeration and corrosion reduction, can solve the problems of upper escape and inability to realize aeration protection of the channel floor well, and achieve the effect of reducing project cost and good aeration and corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

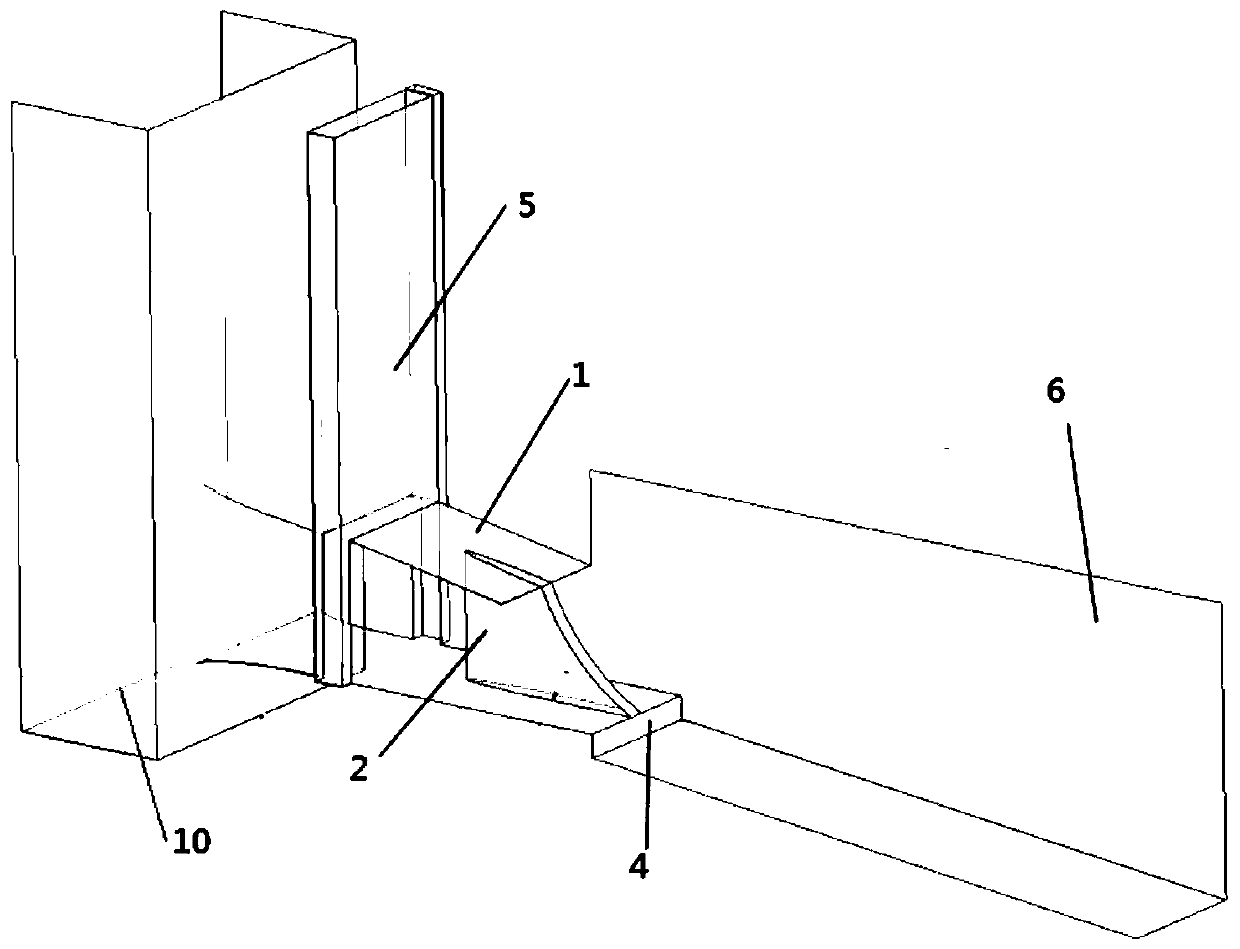

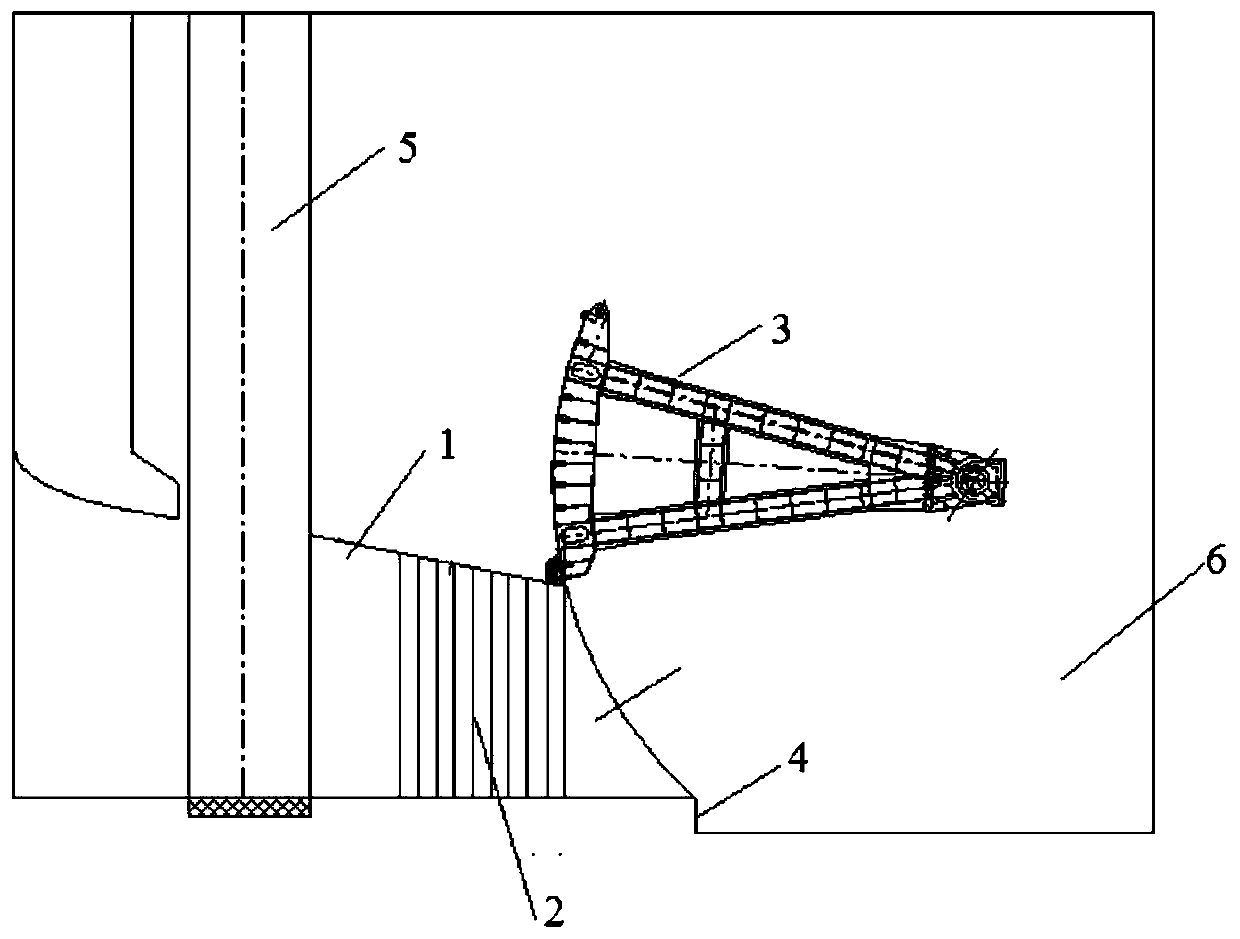

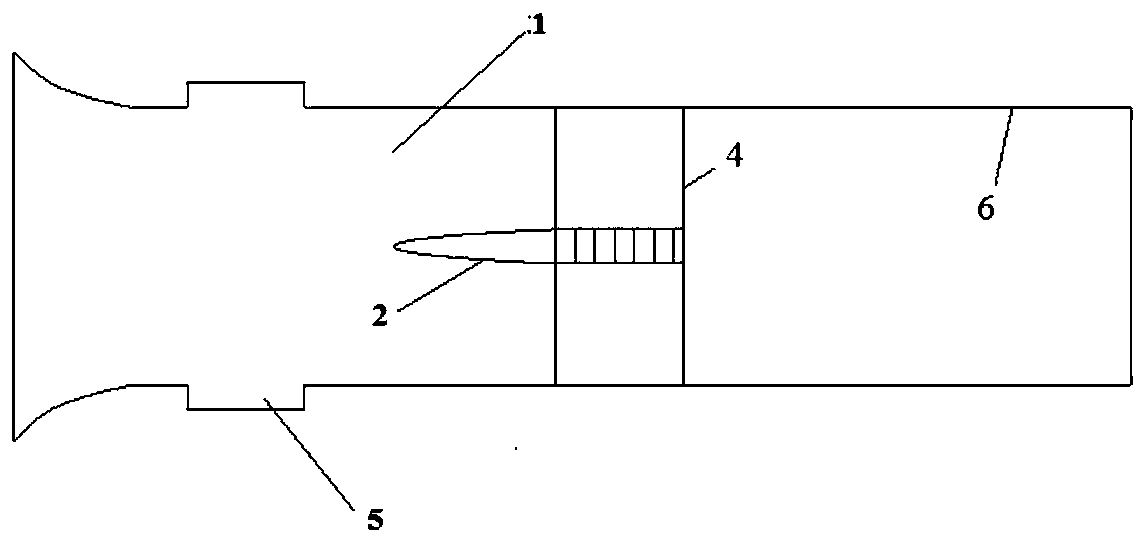

Embodiment 1

[0029] One-gate multi-hole type open channel pressurized inlet full-section aerated hydraulic facility: at the orifice of the open channel pressurized inlet section 1, a vertical partition wall 2 is set along the direction of water flow in the pressurized water body, and the hole in the pressurized inlet section The outlet is separated into two parallel narrow and deep independent overcurrent channels, and the two overcurrent channels are opened and closed simultaneously by the same working gate 3, and a drop valve is set at the connection between the bottom plate of the orifice of the pressure inlet section and the bottom plate of the open flow section 6. The ridge is 4, and the height of the falling ridge is 1m. The cross-section of the partition wall is streamlined, the water facing surfaces on both sides are smooth and gradually changing curved surfaces, and the thickness of the end is 1 / 4 of the height of the partition wall. The working gate is an arc gate, and the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com