Double-Ogee curve type bottom aeration facility for inhibiting cavity backwater

It is a curved and wok technology, applied in the field of aeration facilities, which can solve the problems of increasing investment, impact damage to the floor, and damage to the flow state, so as to improve the effect of aeration and corrosion reduction, avoid cavitation damage, and increase aeration cavity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

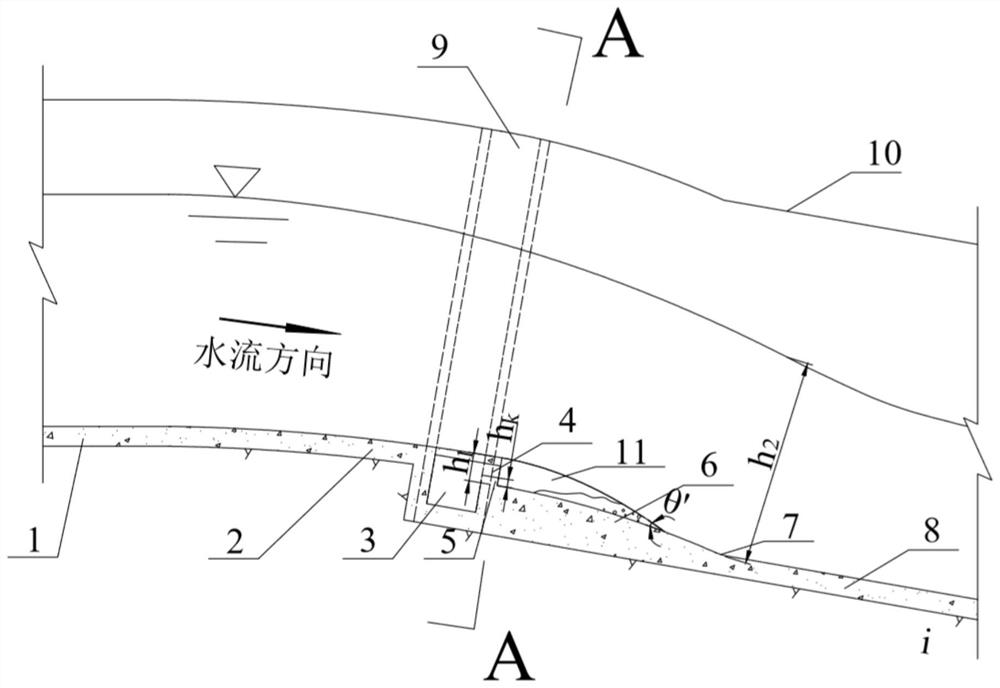

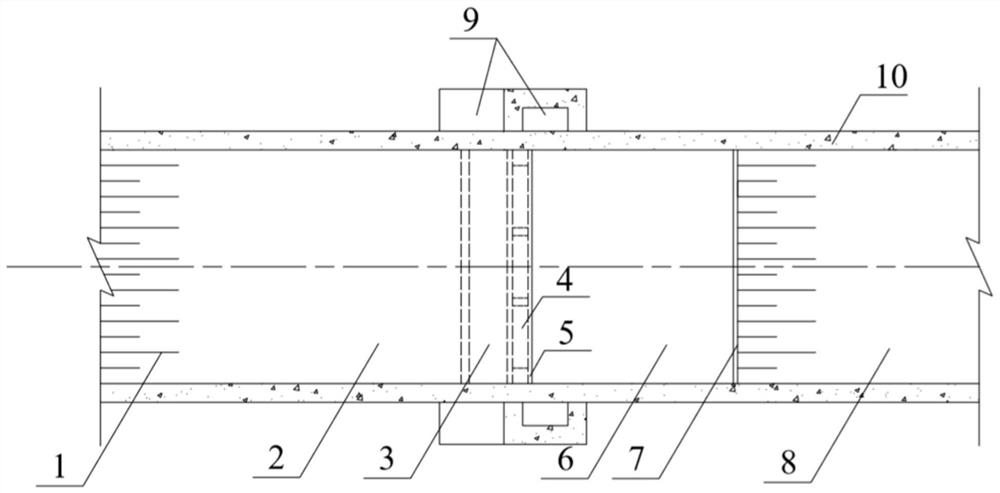

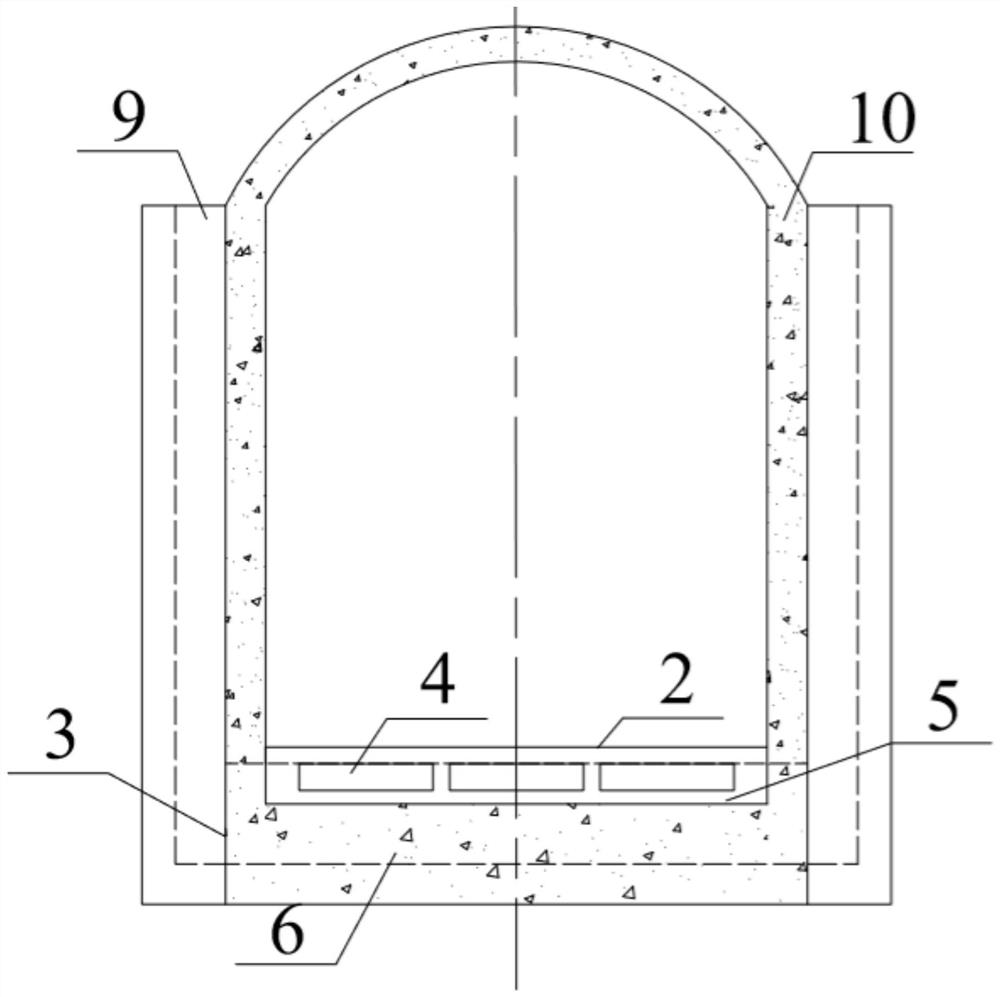

Embodiment 1

[0027] The discharge structure in this embodiment is a spillway, the design water level elevation of the reservoir upstream of the spillway is 2707.00m, and the flow rate is 4400m 3 / s. The spillway consists of an inlet control section, a non-pressure tunnel section and an outlet deflecting section. The entrance control section adopts an open entrance, the initial pile number of the entrance is 0+000.000m, the bottom elevation of the entrance is 2669.00m, the overflow weir type of the entrance is WES weir, and the weir crest elevation is 2678.00m. The body of the non-pressure tunnel section is a city gate-shaped section, with a section size (width x height) of 15.0m x 24.0m, of which the height of the straight wall is 19.7m, and the radius of the top arch is 8.7m; The straight slope section is composed of section, Wolch curve connection section, and steep slope straight section. The gentle slope line section starts from pile number 0+046.000m, the slope of the floor is i=0.01...

Embodiment 2

[0035] The discharge structure in this embodiment is a spillway tunnel, the design water level elevation of the reservoir upstream of the spillway tunnel is 2574.00m, and the flow rate of the spillway tunnel is 3300m 3 / s. The spillway consists of an inlet control section, a non-pressure tunnel section and an outlet deflecting section. The entrance control section adopts an open entrance, the initial pile number of the entrance is 0+000.000m, the bottom elevation of the entrance is 2538.00m, the overflow weir type of the entrance is WES weir, and the weir crest elevation is 2550.00m. The body of the non-pressure tunnel section is a city gate-shaped section, with a section size (width x height) of 15.0m x 24.0m, of which the height of the straight wall is 19.7m, and the radius of the top arch is 8.7m; The straight slope section is composed of a section, a Wage curve connecting section, and a steep straight line section. The straight section of a gentle slope starts at the pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com