Decorative plate

A technology for decorative panels and card slots, applied in floors, coverings/linings, buildings, etc., can solve the problems of obvious joints of decorative panels, large material loss ratio, cumbersome decoration, etc., achieve good support and reinforcement, and save energy Material, the effect of improving accuracy and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

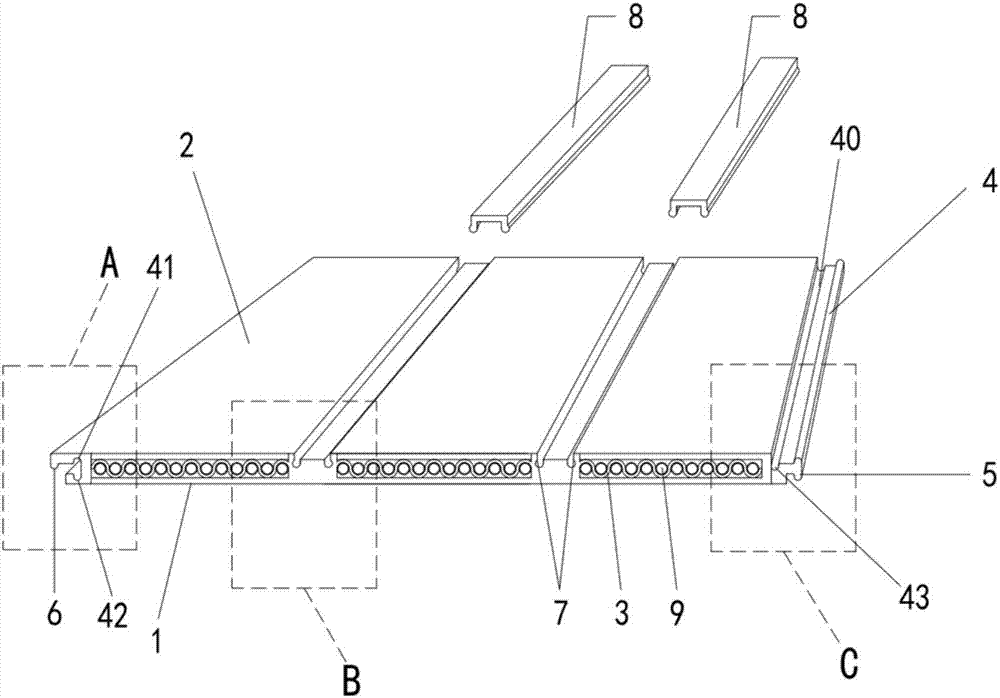

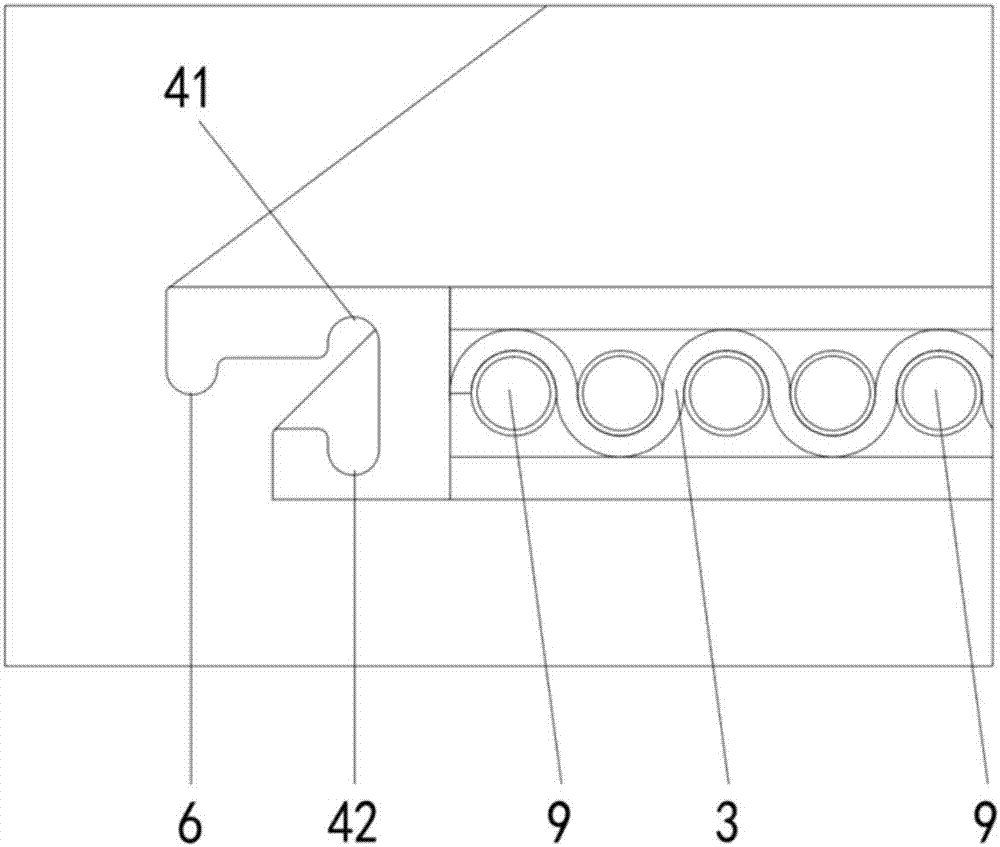

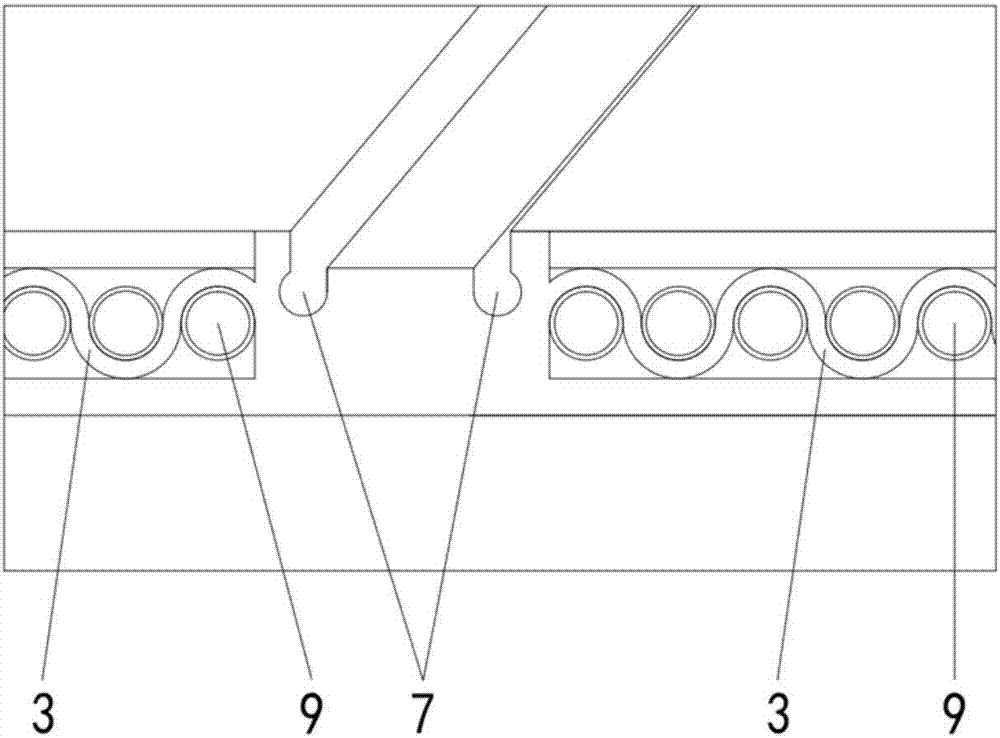

[0029] see Figure 1-6 , a decorative plate, which includes a surface layer 1 and a bottom surface 2, there is an interlayer 3 with a combination of waves and cylindrical holes in the cross section between the surface layer 1 and the bottom surface 2, which is formed by a high-temperature and high-pressure extrusion die of a screw, and then passed through It is formed by cooling and shaping. The left and right sides of the decorative plate are respectively provided with snap-in parts 4, 5, 6 and slots 41, 42, 43 that can be snap-connected to each other. The snap-in parts 4, 5, 6 and The card slots 41, 42, 43 are three-slot and three-buckle front and back buckle structures (see Figure 4 ), the clamping part 4 and the clamping part 5 are in a symmetrical shape, and a groove 40 and a clamping groove 43 are continuously provided on the clamping part 4 along the direction of the bottom surface 2; on the other side of the plate, a clamping part 6 is provided , and card slot 41 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com