Stable-type decorative plate

A decorative board, stable technology, applied in the field of decorative materials, can solve the problems of obvious joints of decorative boards, large proportion of material loss, cumbersome decoration, etc., achieve good support and reinforcement, save materials, excellent antibacterial properties and resistance The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

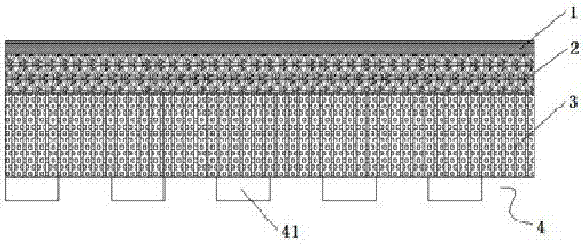

[0017] A stable decorative plate, characterized in that it includes a surface coating 1, a mixed fiber layer 2, a plate layer 3, and a connecting protrusion layer 4 arranged in sequence, and the mixed fiber layer is a urad grass fiber / polylactic acid fiber layer, The connection protrusion layer is composed of symmetrically arranged rectangular elastic protrusions 41; the plate layer includes the following components in parts by weight: 17 parts of polyvinyl acetate, 13 parts of reed fiber, 8 parts of non-alkali chopped glass fiber parts, 7 parts of kaolin clay particles, 9 parts of sodium alginate, 14 parts of basalt fiber, 19 parts of mannitol, and 11 parts of silane coupling agent.

[0018] Further said non-alkali chopped glass fiber has a diameter of 120nm and a monofilament length of 9um;

[0019] Further, the particle size of the kaolin particles is 14um.

[0020] Further, the diameter of the basalt fiber is 230nm.

[0021] Further, the elastic protrusions are polyacryl...

Embodiment 2

[0027] A stable decorative plate, characterized in that it includes a surface coating, a mixed fiber layer, a plate layer, and a connecting protrusion layer arranged in sequence, the mixed fiber layer is a ulagrass fiber / polylactic acid fiber layer, and the connecting protrusion The block layer is composed of symmetrically arranged rectangular elastic protrusions; the plate layer includes the following components in parts by weight: 29 parts of polyvinyl acetate, 25 parts of reed fiber, 13 parts of non-alkali chopped glass fiber, and 15 parts of kaolin particles 16 parts of sodium alginate, 21 parts of basalt fiber, 25 parts of mannitol, and 23 parts of silane coupling agent.

[0028] The diameter of further described non-alkali chopped glass fiber is 180nm, and the monofilament length is 13um;

[0029] Further, the particle size of the kaolin particles is 19um.

[0030] Further, the diameter of the basalt fiber is 290nm.

[0031] Further, the elastic protrusions are polyacr...

Embodiment 3

[0034] A stable decorative plate, characterized in that it includes a surface coating, a mixed fiber layer, a plate layer, and a connecting protrusion layer arranged in sequence, the mixed fiber layer is a ulagrass fiber / polylactic acid fiber layer, and the connecting protrusion The block layer is composed of symmetrically arranged rectangular elastic protrusions; the plate layer includes the following components in parts by weight: 22 parts of polyvinyl acetate, 19 parts of reed fiber, 10 parts of non-alkali chopped glass fiber, 12 parts of kaolin particles 11 parts of sodium alginate, 17 parts of basalt fiber, 23 parts of mannitol, and 17 parts of silane coupling agent.

[0035] The diameter of further described alkali-free chopped glass fiber is 150nm, and the length of monofilament is 11um;

[0036] Further, the particle size of the kaolin particles is 17um.

[0037] Further, the diameter of the basalt fiber is 260nm.

[0038] Further, the elastic protrusions are polyacr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com