Idle safety door lock

A security door lock and lock lever technology, applied in the field of locks, can solve the problems of easy to cause serious accidents, broken and damaged locking structures, waste of escape time, etc., and achieve the effect of improving safety and anti-theft performance, avoiding loosening and damage, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

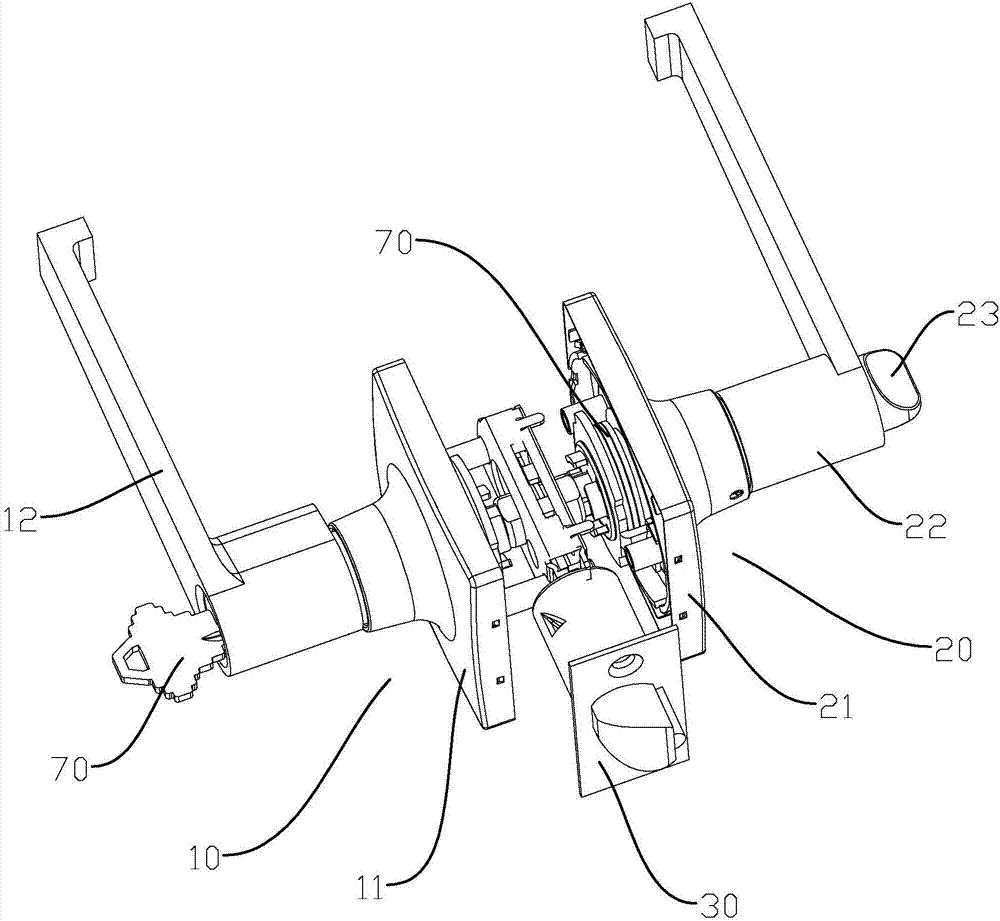

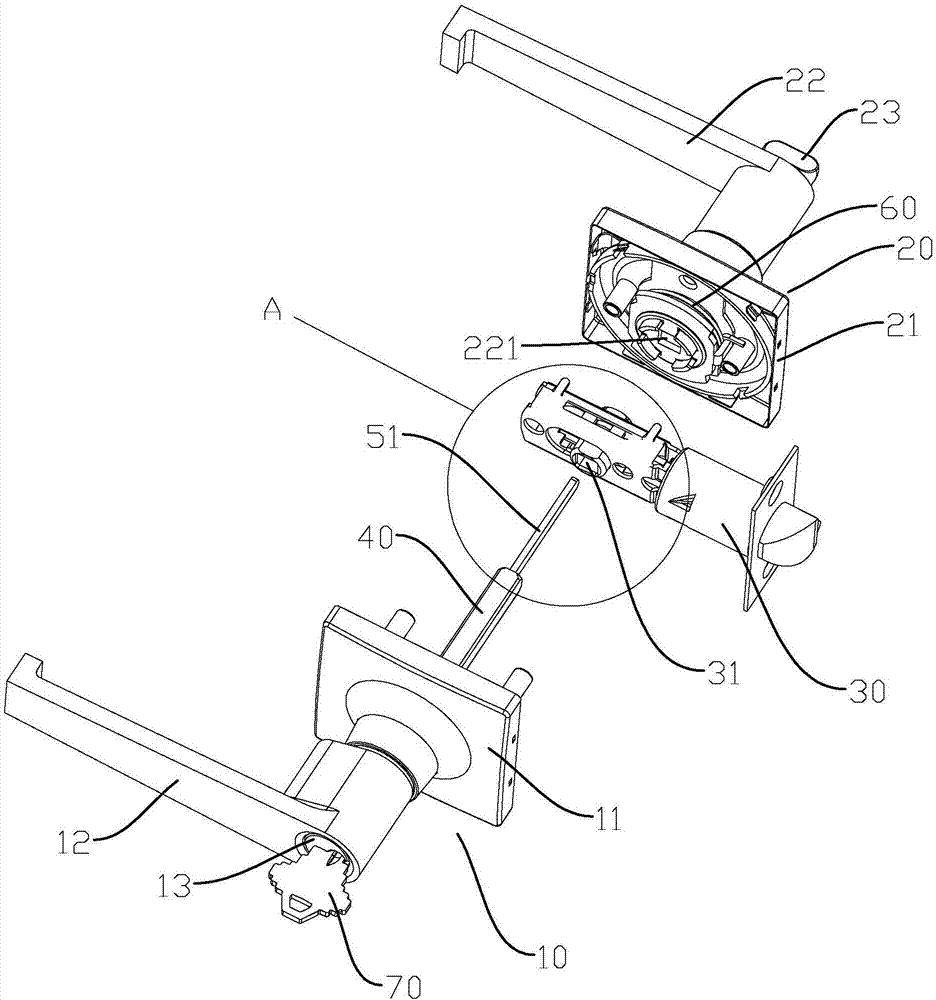

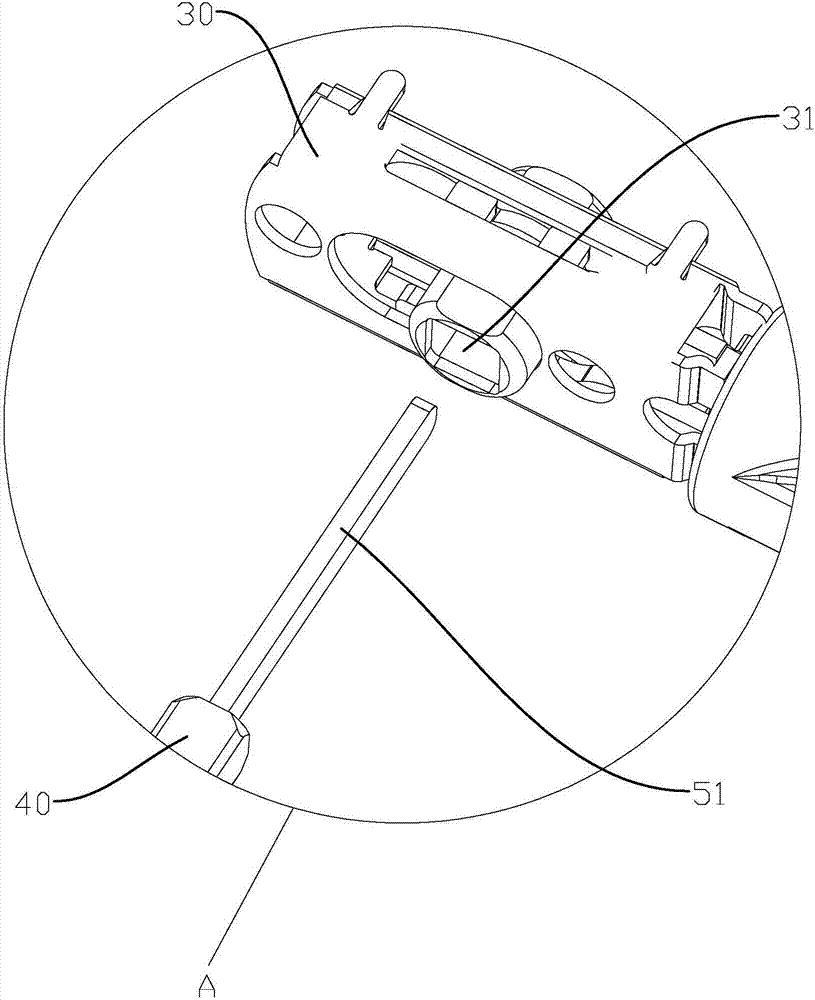

[0027] refer to Figure 1 to Figure 7 , a idling safety door lock, comprising: a front panel assembly 10, including a front base 11 and a front handle 12 rotatably arranged on the front base 11; a rear panel assembly 20, a rear base 21 and a rotatably arranged rear The rear handle 22 on the base 21; the lock body 30; the rotatable transmission part 40, the transmission part 40 is connected with the lock body 30, and the transmission part 40 can be driven to rotate to control the lock when the front handle 12 and the rear handle 22 rotate The unlocking and locking action of the body 30; the front panel assembly 10 is provided with a lock core 13, the front handle 12 is connected with the transmission part 40 through a clutch mechanism, and the lock core 13 can switch the front handle 12 and the transmission part 40 through the clutch mechanism between engaged and disengaged states. In the present invention, because the front handle 12 is connected with the transmission part 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com