Self-aligning torsion hinge

A self-aligning and torsion technology, which is applied to door/window accessories, wing leaf parts, wing leaf openers, etc., can solve the problems of inconsistent automatic centering, increased door opening resistance, and uneven shaft force. Achieve the effect of saving effort in the process of opening and closing the door body, reducing the resistance of opening the door, and uniform force on the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

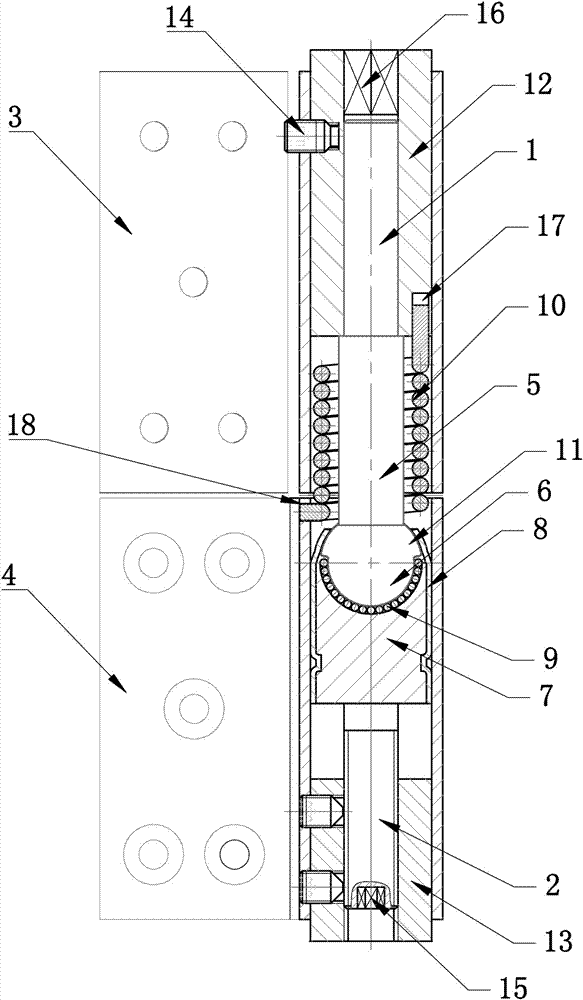

[0017] Embodiment 1: A kind of self-aligning torsion hinge, such as figure 1 As shown, it includes the mandrel and the upper leaf 3 and the lower leaf 4 that are set on the mandrel. The lower leaf is installed on the door frame, and the door body is installed on the upper leaf. The rotation of the door body can drive the upper leaf relative to the lower leaf. The leaf rotates to realize the opening and closing of the door body; the mandrel includes a first mandrel 1 and a second mandrel 2, the first mandrel 1 is covered with a first sleeve 12, and the second mandrel 2 The outer cover is equipped with a second shaft sleeve 13, and the mandrel and the shaft sleeve are fixedly connected by threads; the upper sheet 3 is installed outside the first mandrel through the first shaft sleeve, and the lower sheet 4 is installed on the outside of the first mandrel through the second shaft sleeve. Installed outside the second mandrel, the side walls of the upper leaf and the lower leaf are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap