Turnover device

A flipping device, flipping technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as difficult flipping of large-sized sheets and artificial defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

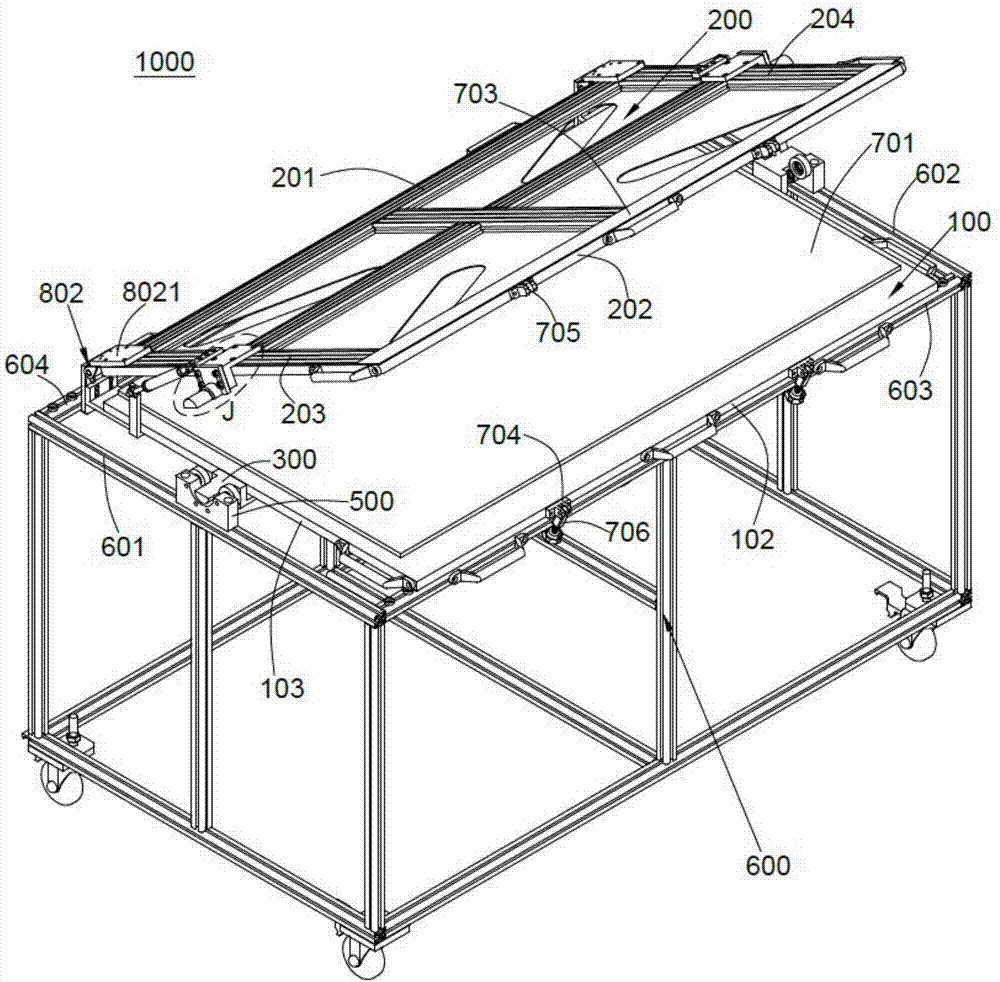

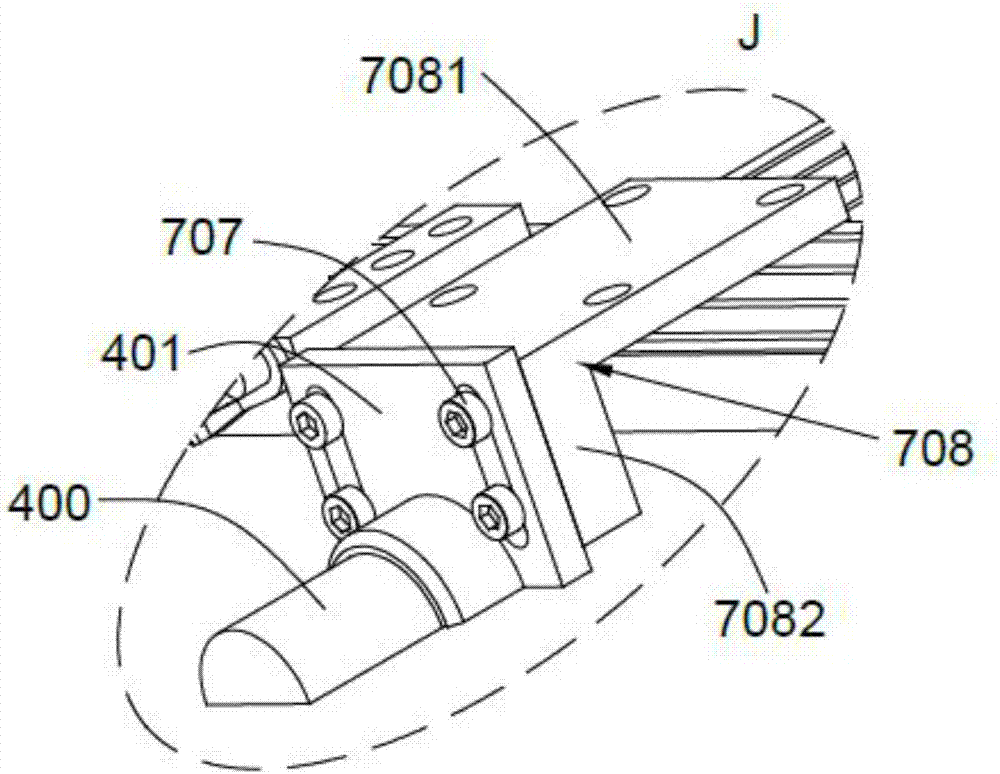

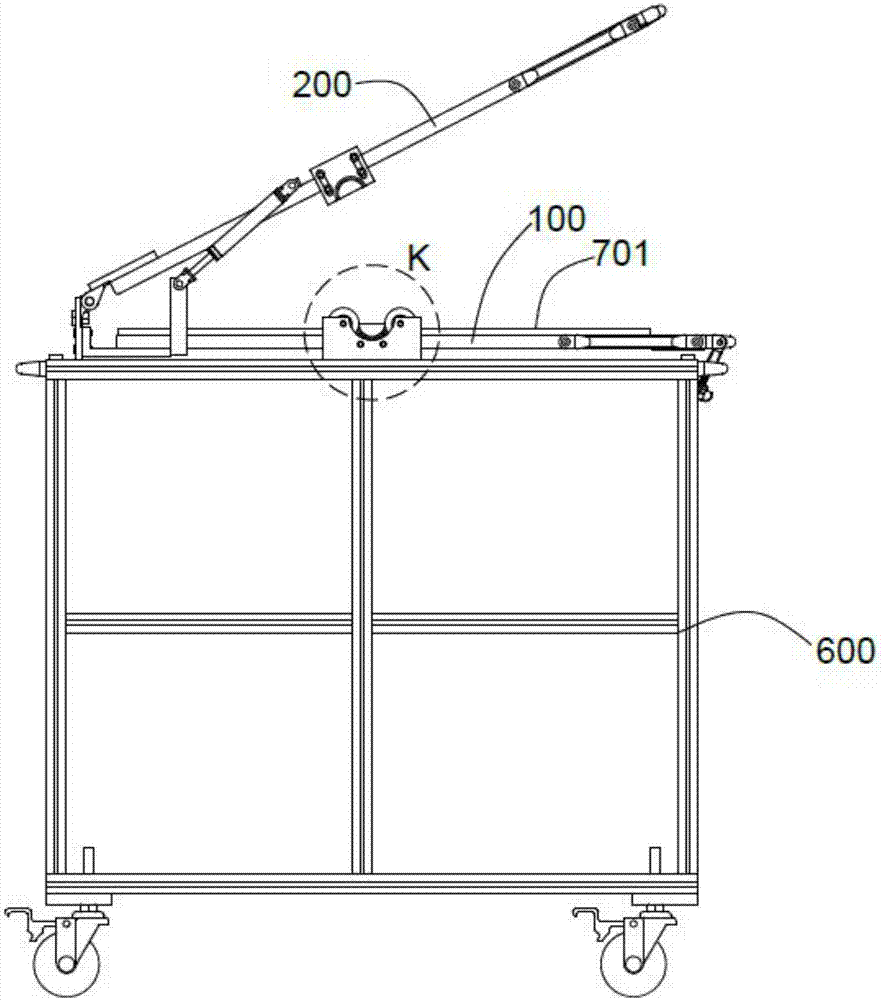

[0039] figure 1 It is a schematic diagram of the initial state of the turning device of the present invention, figure 2 for figure 1 The enlarged schematic diagram at J in the middle, image 3 for figure 1 side view diagram of Figure 4 for image 3 The enlarged schematic at K in middle.

[0040] Please refer to Figure 1 to Figure 4 , a turning device 1000 for turning over a sheet, the turning device 1000 includes a first turning plate 100, a second turning plate 200, a pair of first half shafts 300, a pair of second half shafts 400, a pair of The base 500 and the bracket 600 are rotated.

[0041] Wherein, the first flap 100 has opposite first sides 101 (see Figure 7 ) and the third side 102, and the opposite fifth side 103 and the seventh side 104 (see Figure 7 ), the fifth side 103 and the seventh side 104 are arranged between the first side 101 and the third side 102; a pair of first half shafts of rotation 300 are respectively arranged on opposite sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com