A double-side breaking technique for a vacuum circuit breaker

A vacuum circuit breaker technology, applied in the direction of high-voltage air circuit breakers, circuits, electric switches, etc., can solve the problems that restrict the large capacity of vacuum circuit breakers, complex structure of vacuum circuit breakers, large size of operating mechanism, etc., and achieve favorable Arc extinguishing, excellent breaking performance, and high operating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

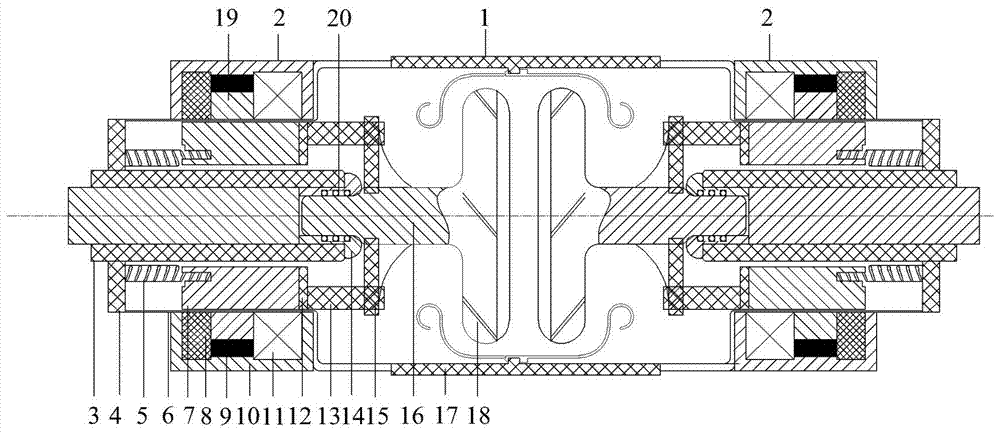

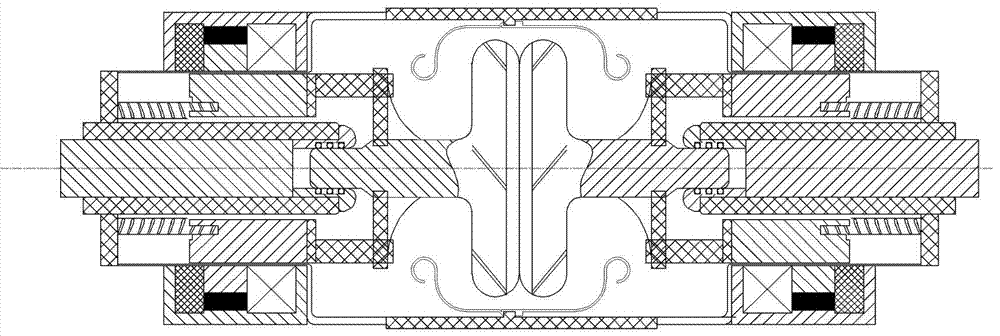

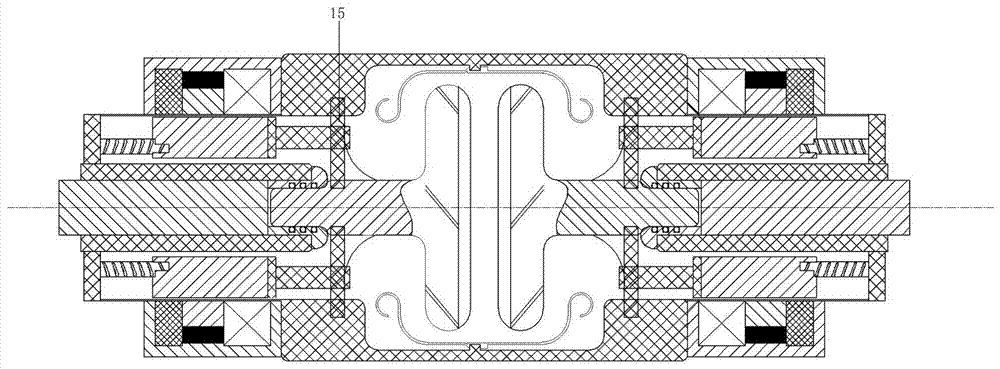

[0028] Such as Figure 1-7 As shown, the present invention includes a vacuum circuit breaker body; the vacuum circuit breaker body includes a double-side magnetic drive mechanism, an electrode system and a double-side main conductive circuit. The electrode system includes a moving electrode assembly 1 and a moving electrode assembly 2; the double-sided magnetic drive mechanism includes a magnetic drive mechanism 1 and a magnetic drive mechanism 2; the bilateral main conductive loop includes a main conductive loop 1 and a main conductive loop 2 The first magnetic drive mechanism is connected to the first moving electrode assembly, and drives the first moving electrode assembly to close or open the second moving electrode assembly through relative motion; The channel connected to the main circuit; the second magnetic drive mechanism is connected to the second moving electrode assembly, and the second driving electrode assembly is driven to close or open with the first moving ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com