A self-controlled temperature type power transformation cabinet

A technology of substation cabinet and temperature type, which is applied in substation/power distribution device casing, substation/switch layout details, substation/switchgear cooling/ventilation, etc., which can solve fire, affect the reliability of internal equipment, and endanger operation personal safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

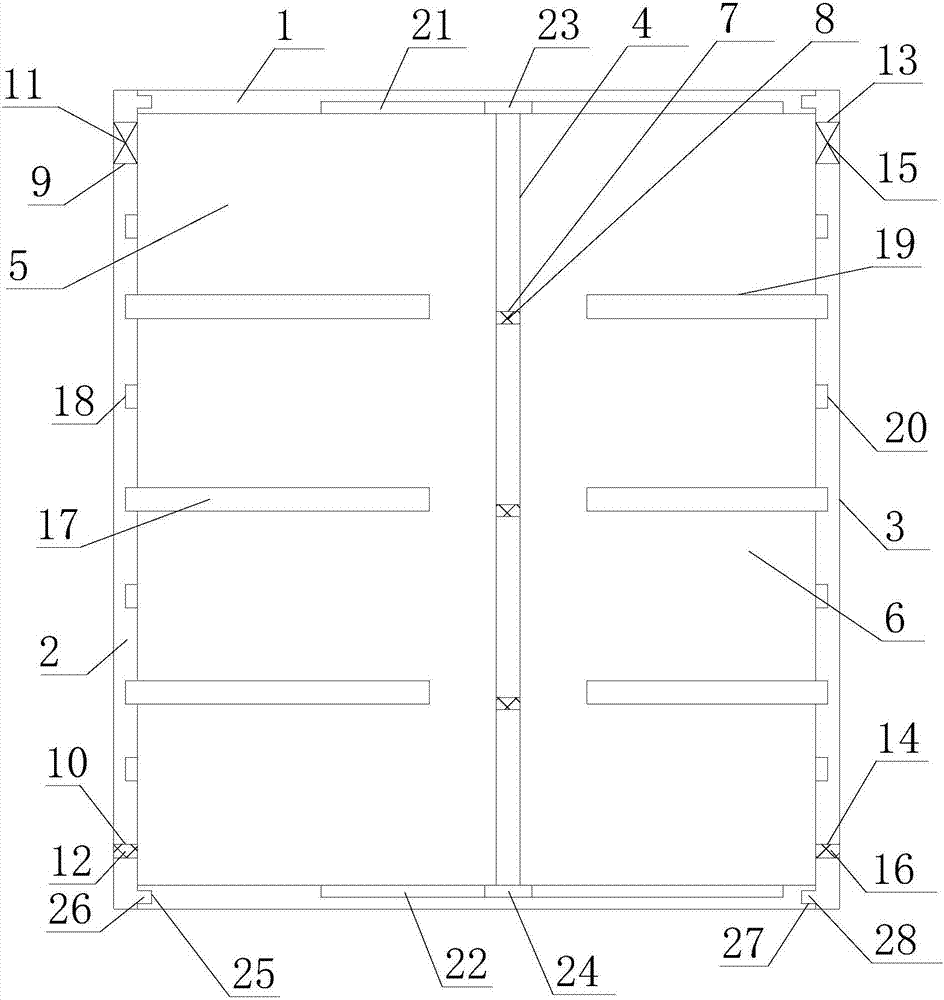

[0015] refer to figure 1 , the present invention proposes a self-temperature control type transformer cabinet, including a cabinet body and a controller, and the cabinet body includes a main body 1, a first cover plate 2 and a second cover plate 3, wherein:

[0016] The main body 1 is a frame structure with openings at both ends. There is a vertical partition 4 inside the main body 1. The vertical partition 4 is parallel to the first cover plate 2 and the second cover plate 3. The inner side of the top plate of the main body 1 is provided with a first chute. 21. The inner side of the bottom plate of the main body 1 is provided with a second chute 22, the first chute 21 and the second chute 22 are on the same vertical plane and the plane where the first chute 21 and the second chute 22 are located is perpendicular to the vertical partition 4, the top of the vertical partition 4 is slidably connected to the first chute 21 through the first slider 23, and the bottom end of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com