Energy-saving environmentally-friendly type distribution room based on quick construction technique

An energy saving, environmental protection, power distribution room technology, applied in substations, buildings, industrial buildings, etc., can solve the problems of construction quality affected by the environment, production efficiency is not high, life cycle is not up to date, etc., to reduce welding Reliance on equipment and personnel qualifications, shortening the construction period, and reducing the effect of air-conditioning load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

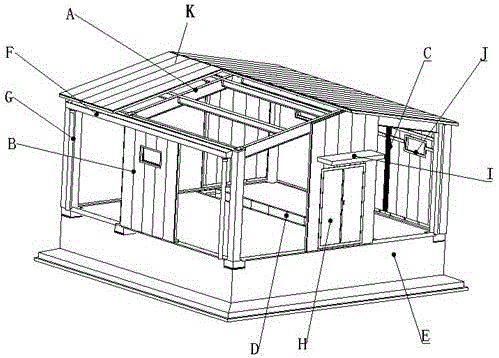

[0023] like figure 1 As shown, an energy-saving and environment-friendly power distribution room based on rapid construction technology, including civil engineering foundation E, steel structure frame A of the power distribution room body, power distribution room door H, power distribution room window J, gutter F, rain Shed I, downpipe G, prefabricated cable trench D, some combined walls B and some combined roofs K.

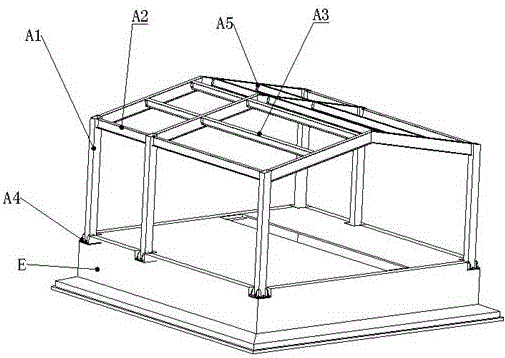

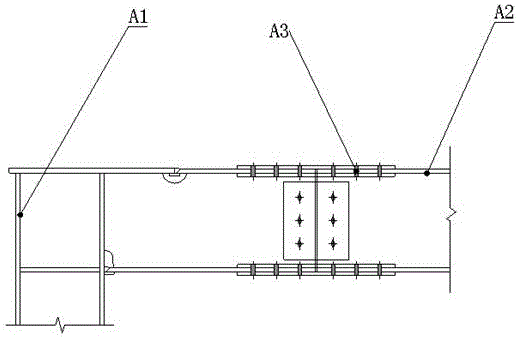

[0024] like figure 2 , 3 , 4, the steel frame A includes steel columns A1, steel beams A2 and purlins A3. All parts are made of welded section steel, and are processed in the factory according to the design requirements, and the surface layer is protected against f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com