Air water-washing purifying unit

A technology of washing unit and purification unit, applied in the field of air purification, can solve problems such as tedious design work, and achieve the effect of reducing cost, easy daily replacement, and easy daily maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

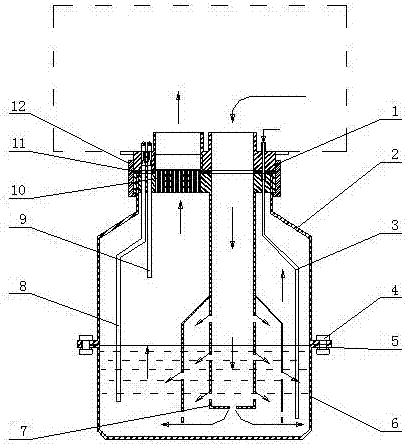

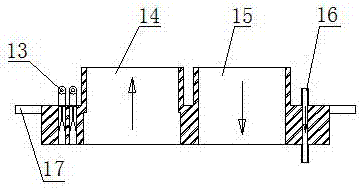

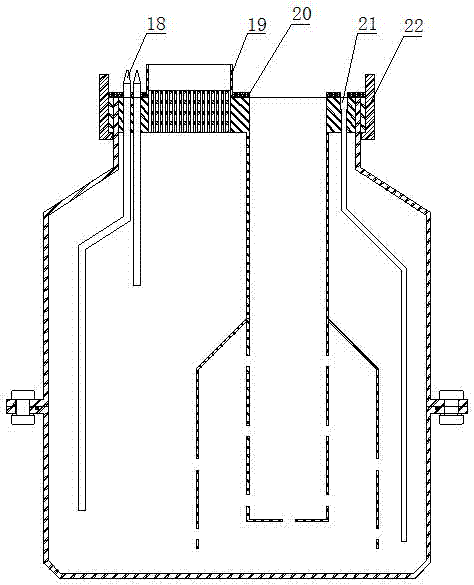

[0023] Such as Figure 1~3 As shown, an air washing and purification unit includes a water washing unit joint 1, an upper chamber 2, and a lower chamber 6; the water washing unit joint 1 is connected to the air purifier, and the water washing unit joint 1 is respectively provided with a top cover 11, an air intake Port 15 and air outlet port 14; the lower part of the air inlet port 15 is connected to the air diffuser 7, the side of the air diffuser 7 is provided with a water supply pipe 3, and the side of the air outlet port 14 is provided with a water stopper 10 and a water level detection switch, the water level detection switch includes a low water level The detection switch 8 and the high water level detection switch 9, the low water level detection switch 8 is located in the upper cavity 2, the high water level detection switch 9 is located in the lower cavity 6; the upper cavity 2 and the lower cavity 6 are connected by bolts 4, and the Water is provided; the top cover a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com