Long-span anti-impact multidirectional displacing comb-shaped plate type bridge stretching device

A multi-directional displacement and telescopic device technology, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve problems such as device bending deformation, affecting driving safety, bolt loosening or comb teeth breaking, so as to avoid warping deformation and realize Multi-directional displacement function, solve the effect of poor dustproof and waterproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

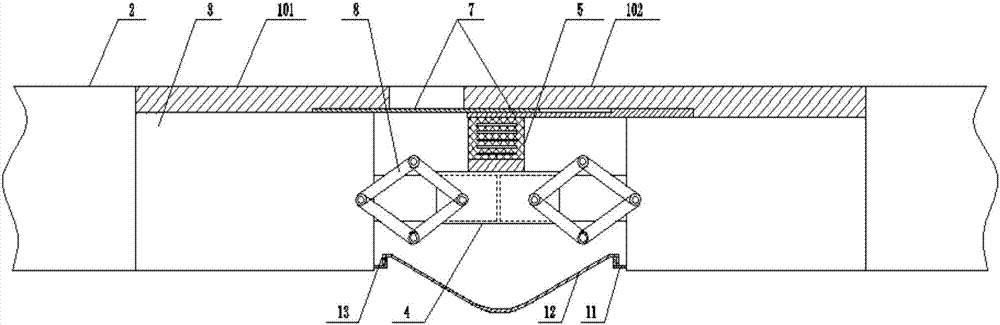

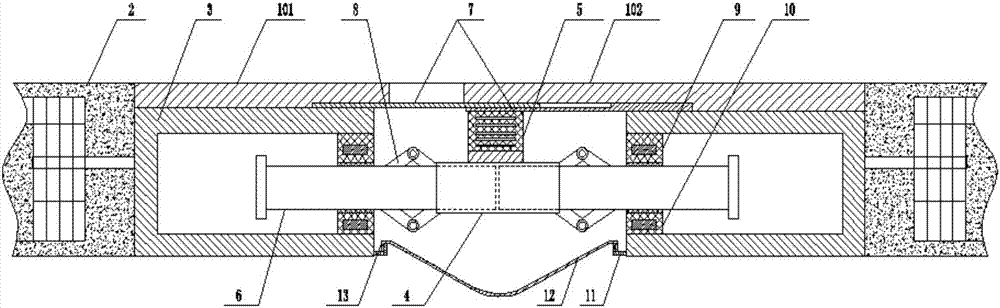

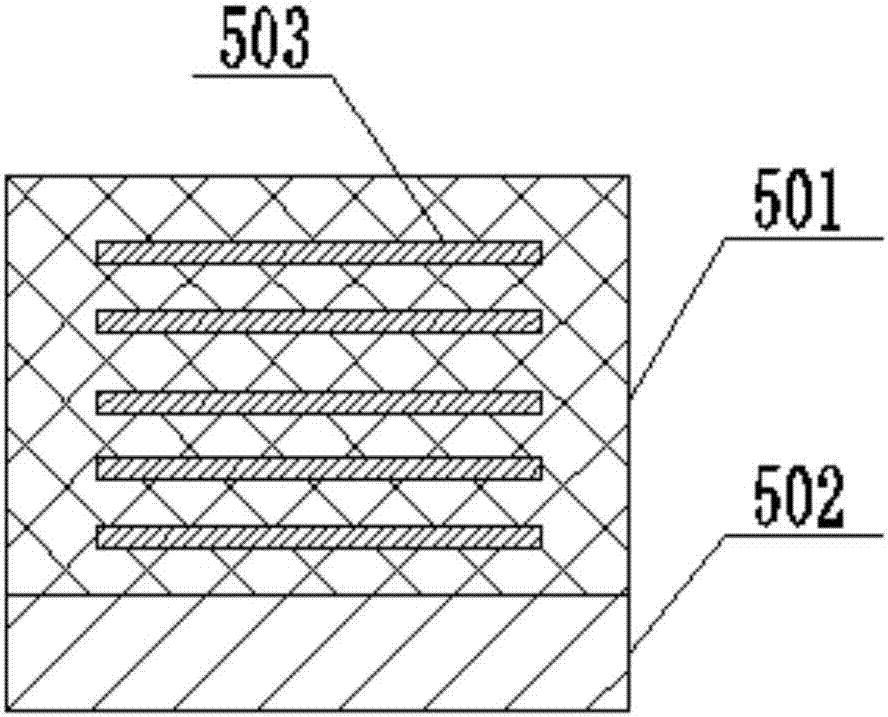

[0016] The invention relates to a large-span impact-resistant multi-directional displacement comb-shaped plate bridge expansion device, which is arranged between two adjacent bridge beam ends 2, and includes a comb-tooth plate mechanism and a telescopic mechanism fixed at its lower end. Both the tooth plate mechanism and the outer end of the telescopic mechanism are fixedly connected to the pre-embedded structure in the bridge beam end 2. The comb tooth plate mechanism includes a fixed comb tooth plate 101 and a movable comb tooth plate 102 that are plugged and matched with each other. The bottom of the plate 101 and the movable comb plate 102 are respectively provided with a horizontal sliding steel plate 7, and the two horizontal sliding steel plates 7 are overlapped up and down to form a sliding fit; The displacement box 3 below the plate 102 is provided with a sliding mechanism between the two displacement boxes 3, and the sliding mechanism includes crossbeams 6 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com