Offset-bow centralizer device

The technology of a centralizer and an eccentric bow is applied in the field of cementing tools for petroleum development, and can solve the problems of limited centralizing effect of rigid centralizers and elastic centralizers, large friction resistance of casings, and small flow area, so as to improve displacement efficiency, Large annular flow area, reducing the effect of welding points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

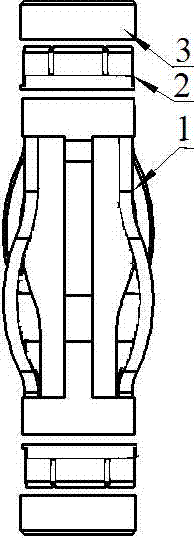

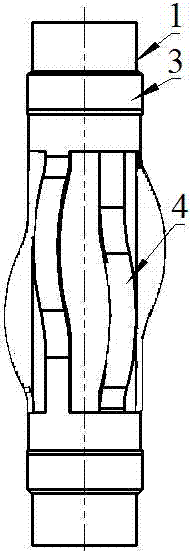

[0025] This embodiment provides a figure 1 , figure 2 The partial bow centralizer device shown includes a centralizer body 1, and both ends of the centralizer body 1 are provided with stop rings, and the centralizer body 1 is a hollow structure, including a plurality of The supporting ribs 4, and there is a gap between two adjacent supporting ribs 4, the supporting ribs 4 are asymmetric partial bow structures, and the arcuate parts of two adjacent asymmetric partial bow structures are arranged in a staggered manner.

[0026] The eccentric centralizer device provided in this embodiment is installed on the surface of the casing, the main body 1 of the centralizer is fixed by stop rings at both ends, and the support ribs 4 evenly distributed in the circumferential direction are asymmetrical eccentric structures, increasing the annular space The circulation area can effectively improve the displacement efficiency of circulating drilling fluid. When the casing enters the deviated...

Embodiment 2

[0028] On the basis of Embodiment 1, this embodiment provides a partial bow centralizer device, the stop ring includes a stop inner ring 2 and a stop outer ring 3, and the stop inner ring 2 and the centralizer body 1 is connected at both ends, and the stop outer ring 3 is sleeved outside the stop inner ring 2 and the two are fixedly connected.

[0029] The stop inner ring 2 includes a compressible structure and a first connection part 7 arranged in sequence from top to bottom, and the stop outer ring 3 includes a compression structure and a second connection part 9 arranged in sequence from top to bottom , the inner diameter of the compression structure is smaller than the outer diameter of the compressible structure, and the stop outer ring 3 and the stop inner ring 2 are connected through the first connecting part 7 and the second connecting part 9 .

[0030] The partial bow centralizer device provided in this embodiment compresses the compressible structure of the inner sto...

Embodiment 3

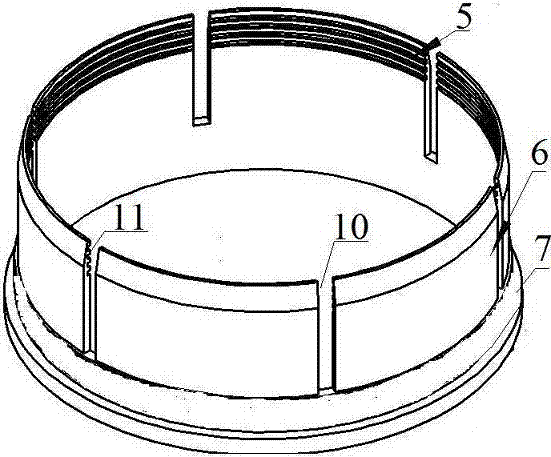

[0032] On the basis of Embodiment 2, this embodiment provides a partial bow centralizer device, the compressible structure is composed of a first compressive cone surface 5, a shrinkable part 6, and a shrinkage gap 10. The first The pressing cone surface 5 is arranged on the top end of the stop inner ring 2, the shrinkable part 6 is connected with the lower part of the first pressing cone surface 5, and the first pressing cone surface 5 is small at the top and large at the bottom;

[0033] The contraction gap 10 runs through the first pressing cone surface 5 and the shrinkable portion 6 , and a plurality of shrinkage gaps 10 are evenly arranged in the circumferential direction, dividing the first pressing cone surface 5 and the shrinkable portion 6 into multiple parts.

[0034] The pressing structure is a second pressing cone surface 8, the second pressing cone surface 8 is arranged at the top of the stop outer ring 3, and the second pressing cone surface 8 is small at the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com