Method for evaluating stratum working parameters applicable to a radial well through jet drillability

A working parameter, radial well technology, used in liquid/gas jet drilling, earthwork drilling, wellbore/well components, etc., which can solve the problem of failure to achieve expected results, bending and resistance, and easy collision of the front end of the nozzle. Problems such as upper stratum rocks, to achieve good guiding and righting effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0025] The embodiment of the present invention provides a method for evaluating the applicable formation working parameters of radial wells by jet drillability, including the following steps:

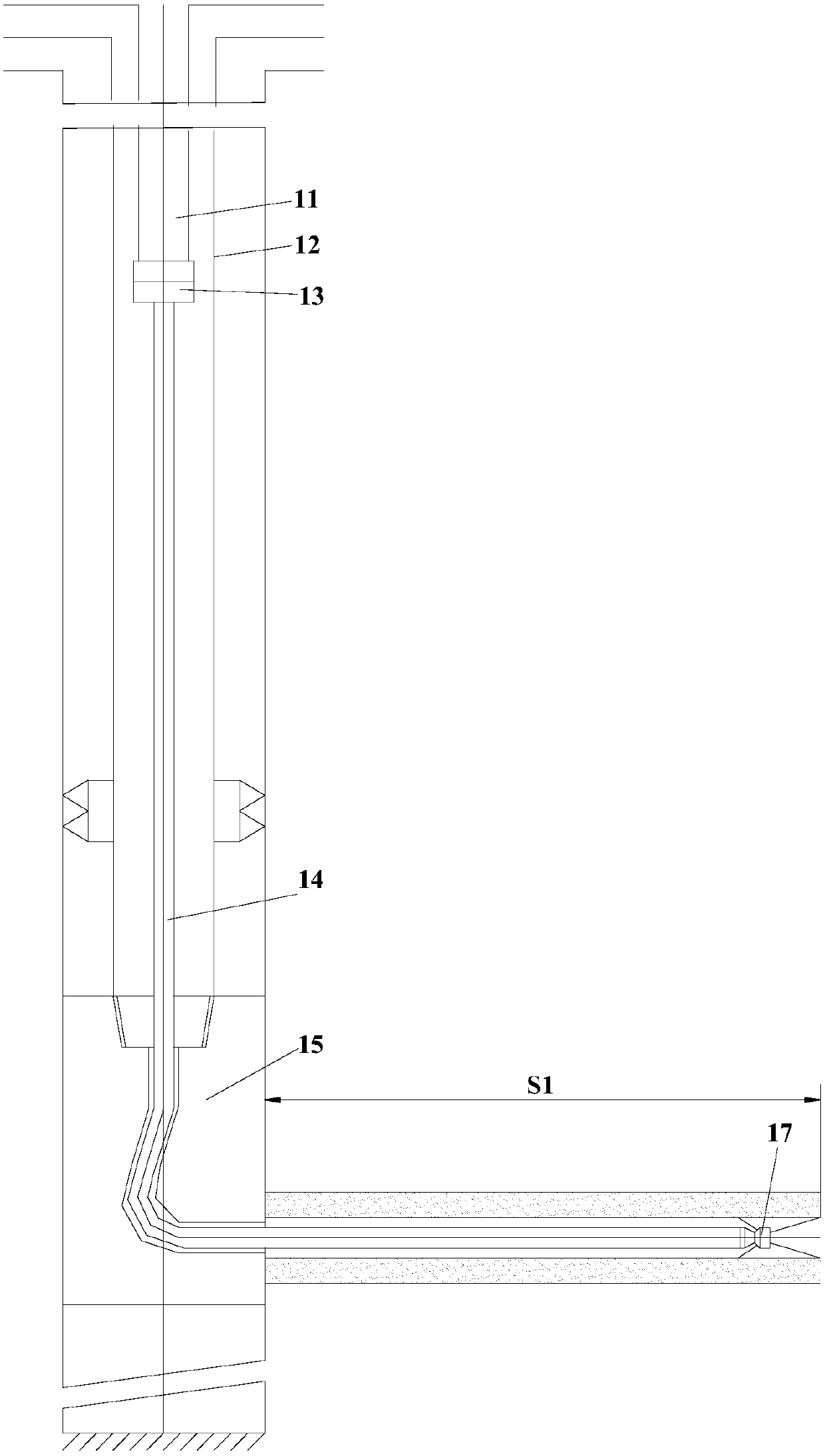

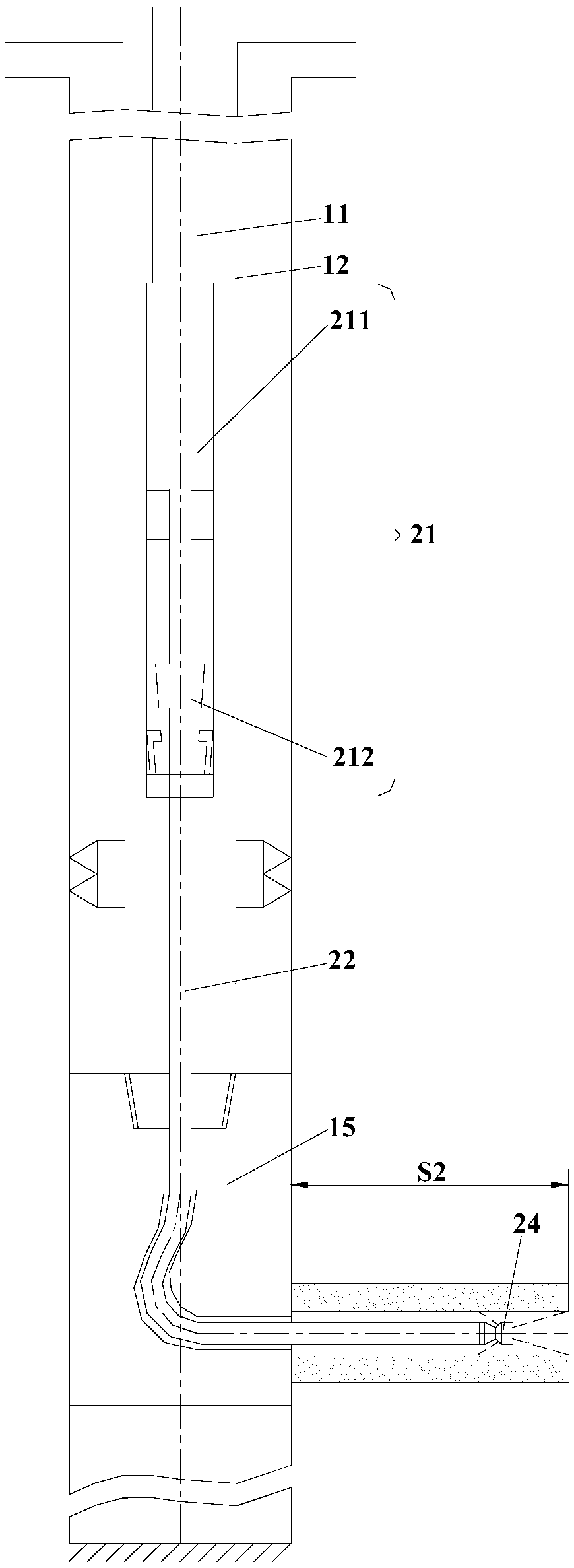

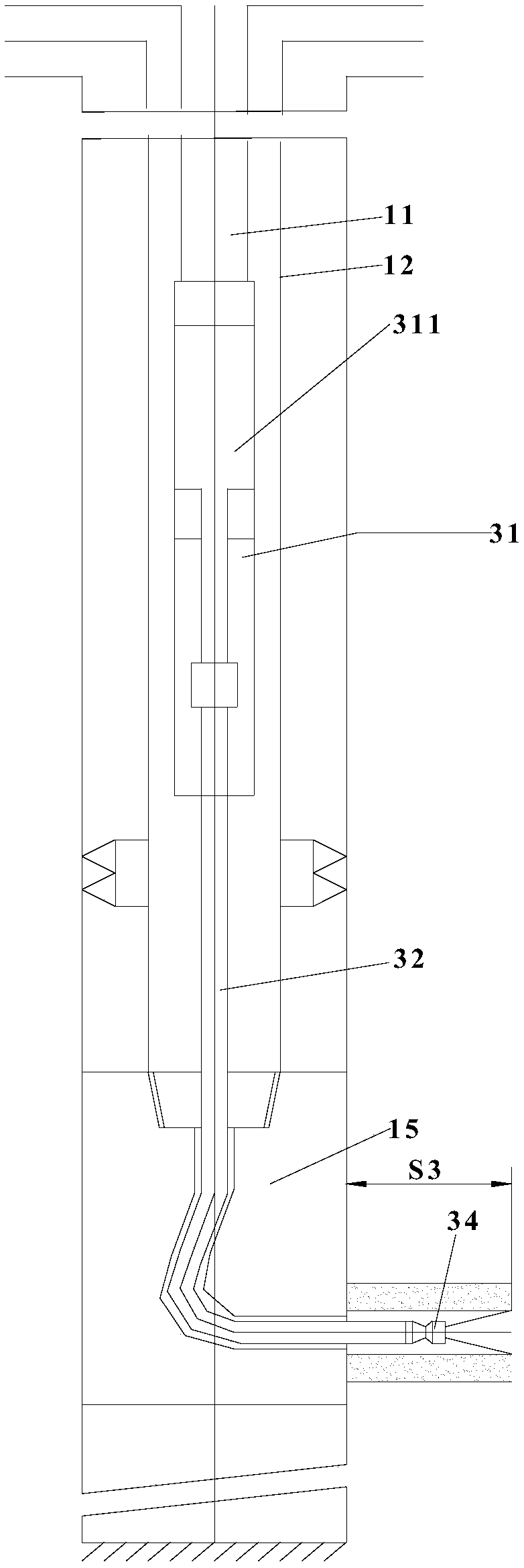

[0026] Step 10, according to the hardness of stratum rock sample, stratum rock sample is divided into loose stratum, medium hard stratum and hard stratum;

[0027] Step 20. When the stratum rock sample is a loose formation, use the self-traction deepening drilling tool to drill, the self-traction deepening drilling tool is connected with the coiled tubing, and the coiled tube is lowered and sent, and the self-traction deepening drilling tool is set having a first spray hose;

[0028] When the stratum r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com