Undercarriage rigidity simulating device and method

A technology of stiffness simulation and landing gear, applied in the field of landing gear simulation, can solve problems such as not found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

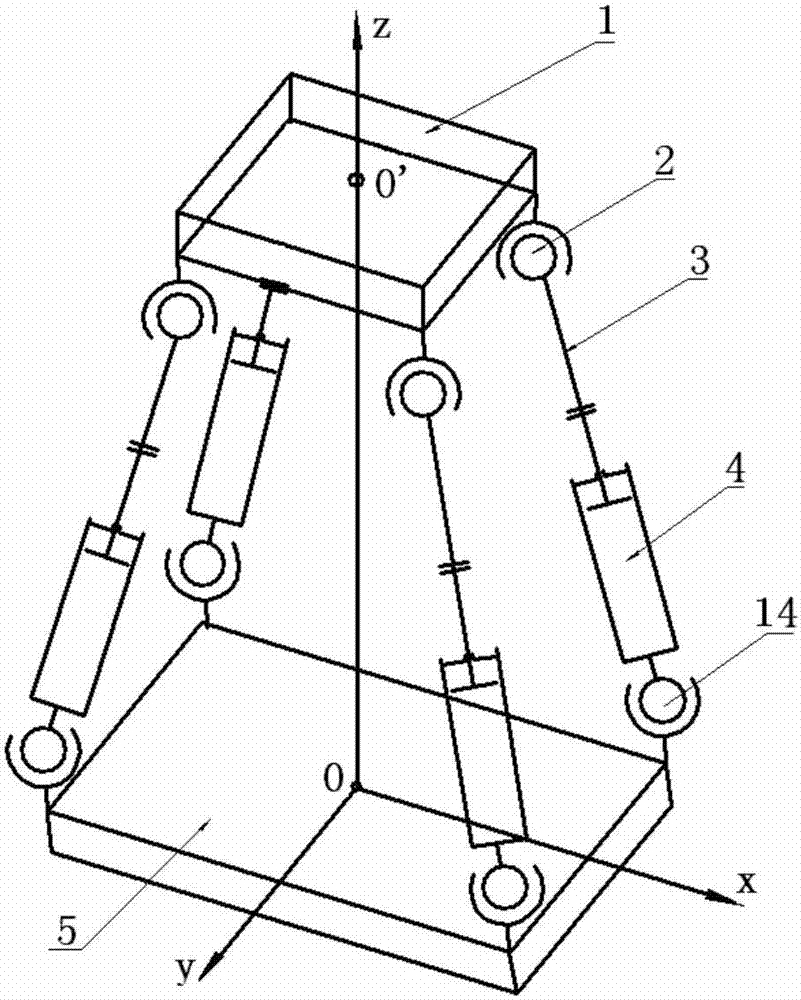

[0092] This embodiment is a landing gear stiffness simulation device, which includes a working platform 1, 4 sets of oil cylinders 4, 8 universal joints 2, a base 5 and 4 sets of adjustable length rods 3. Among them, the 8 universal joints are divided into 4 groups, which are respectively installed on the four corners of the working platform 1 and the four corners of the base 5 . The universal joints on the four corners of the working platform are respectively connected with one end of an adjustable length rod 3; the other ends of the connecting rod are all threaded with the upper end of an oil cylinder 4; The lower ends are all connected with the universal joints on the four corners of the base. Through the above connections, four stiffness simulation devices are constructed.

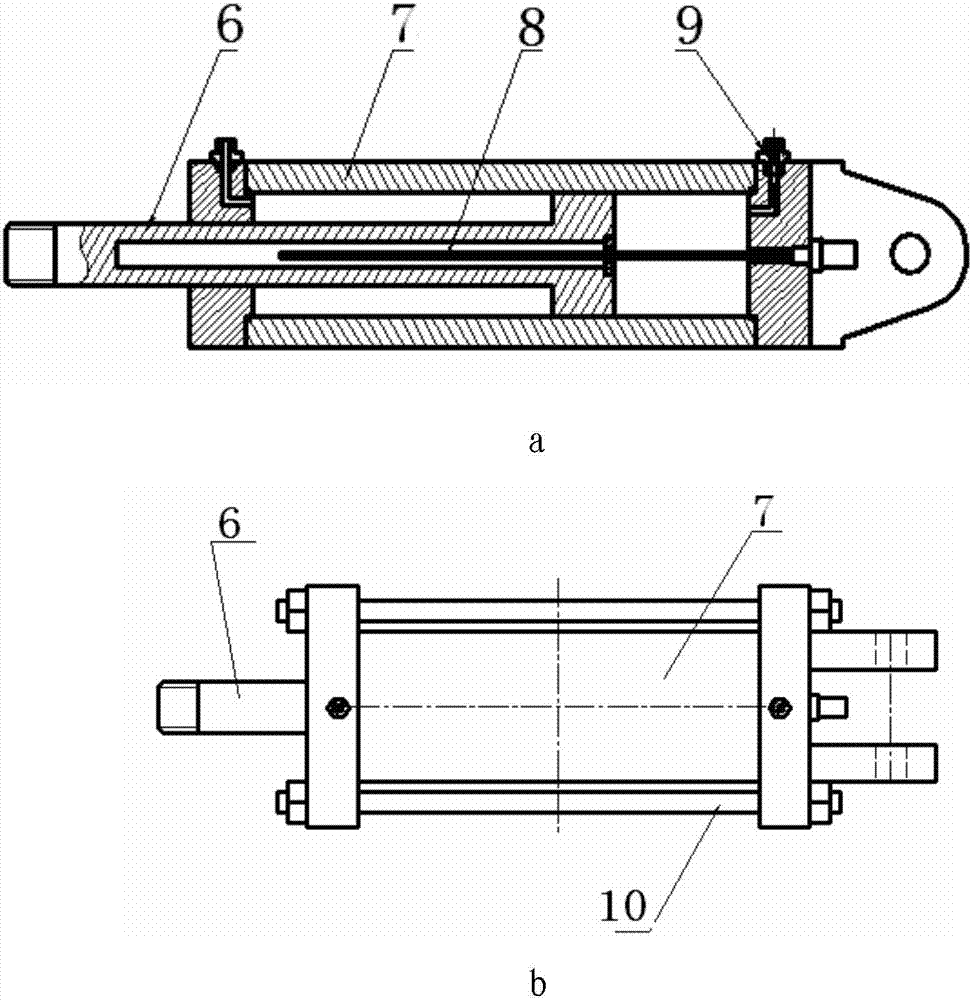

[0093] The oil cylinder 4 includes a piston 6 , a cylinder body and an end cover 7 , a displacement sensor 8 and a nozzle 9 . The hydraulic cylinder block 7 is a hollow rotary body with end caps at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com