Serial robot structural design optimization method

An optimization method and technology of structural design, applied in design optimization/simulation, computer-aided design, instruments, etc., can solve problems such as neglect, difficulty in achieving, and inability to fully reflect stress state, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure design optimization method of the serial robot of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

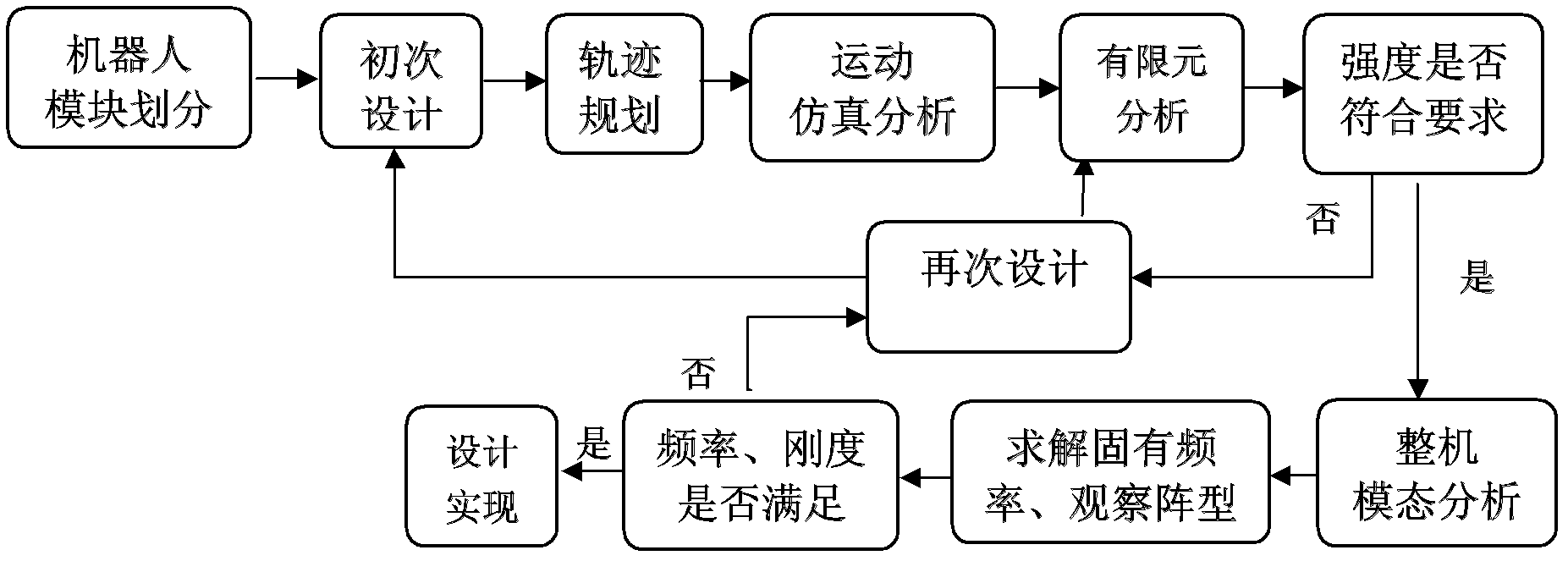

[0028] like figure 1 As shown, the serial robot structure design optimization method of the present invention comprises the following steps:

[0029] (1) The structure of the robot is divided into multiple modules according to the number of degrees of freedom and the transmission structure, including six modules: base, base, turntable, swing arm, small arm and joint top;

[0030] (2) Carry out initial design for each module, that is, initially determine the shape, thickness and transmission mode of the module;

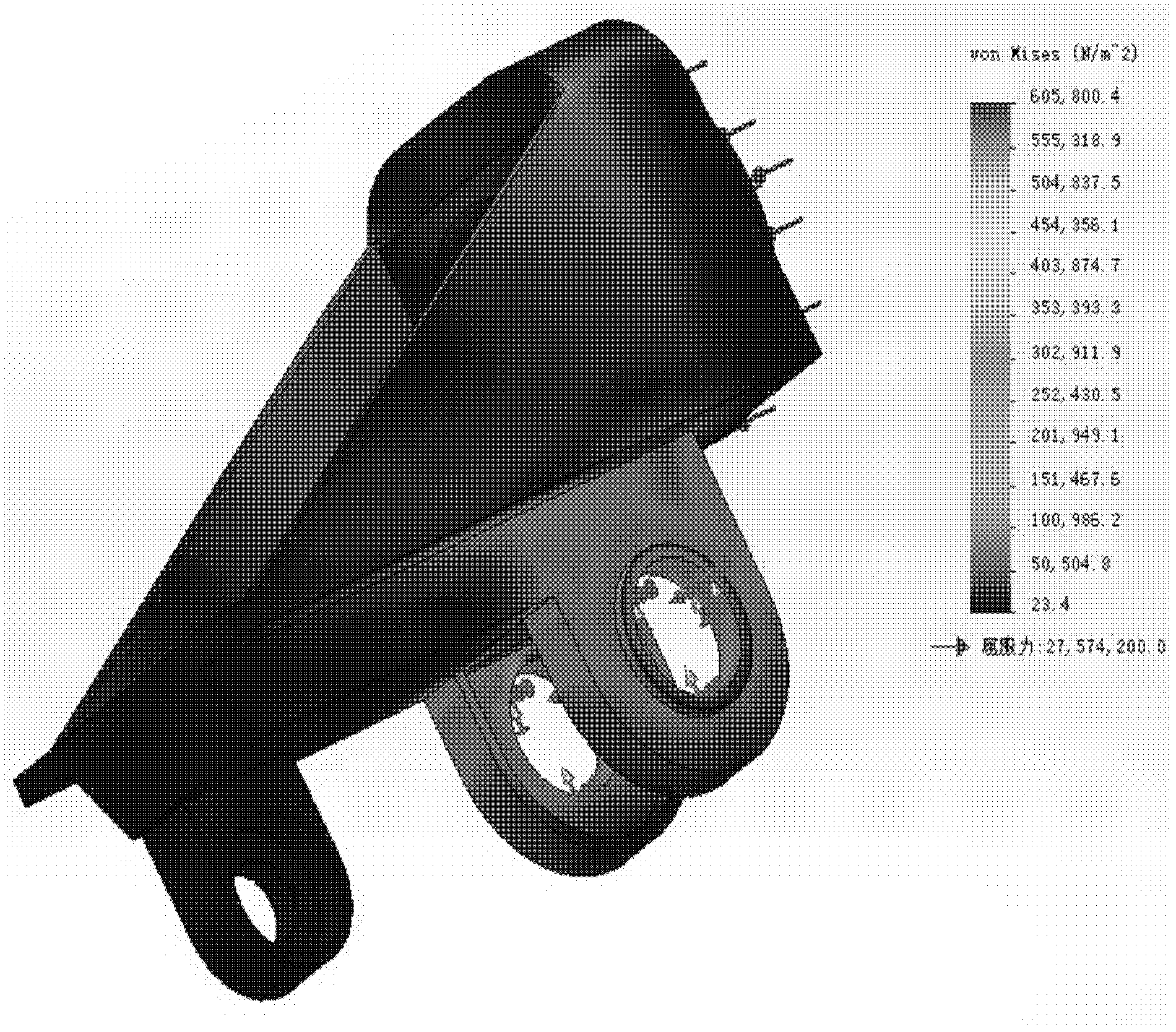

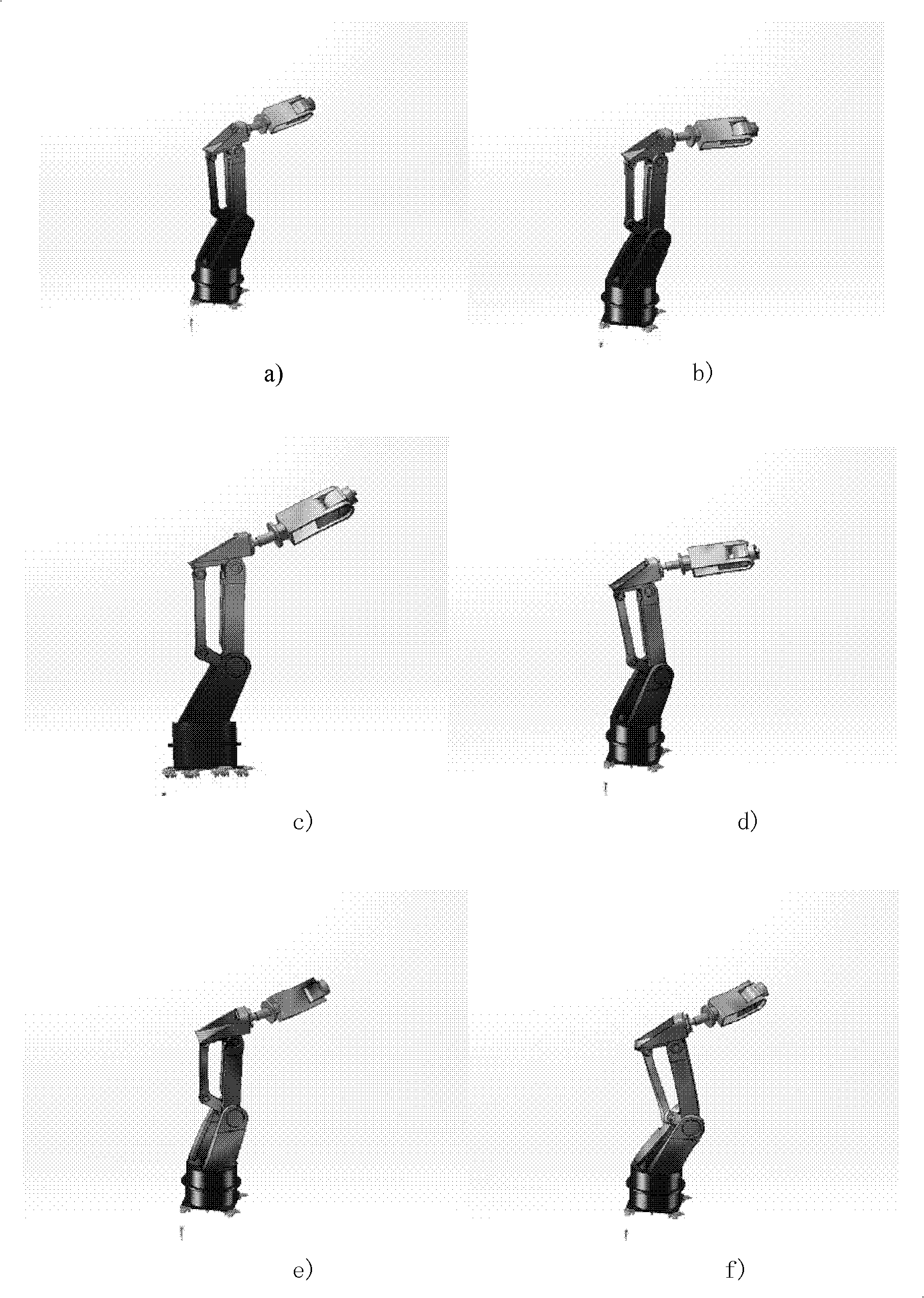

[0031] (3) Carry out finite element analysis to the robot structure of step (2) initial design, optimize structure by the requirement of the strength, rigidity and natural frequency of this robot; Described carrying out finite element analysis comprises following 3 steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com