Power amplifier support frame

A support frame and main body technology, which is applied in the field of car audio power amplifier equipment, can solve the problems of bracket vibration cracking and breaking, large displacement during resonance, waste of materials, etc., and achieves the effects of easy manufacturing, simple and reasonable structure, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

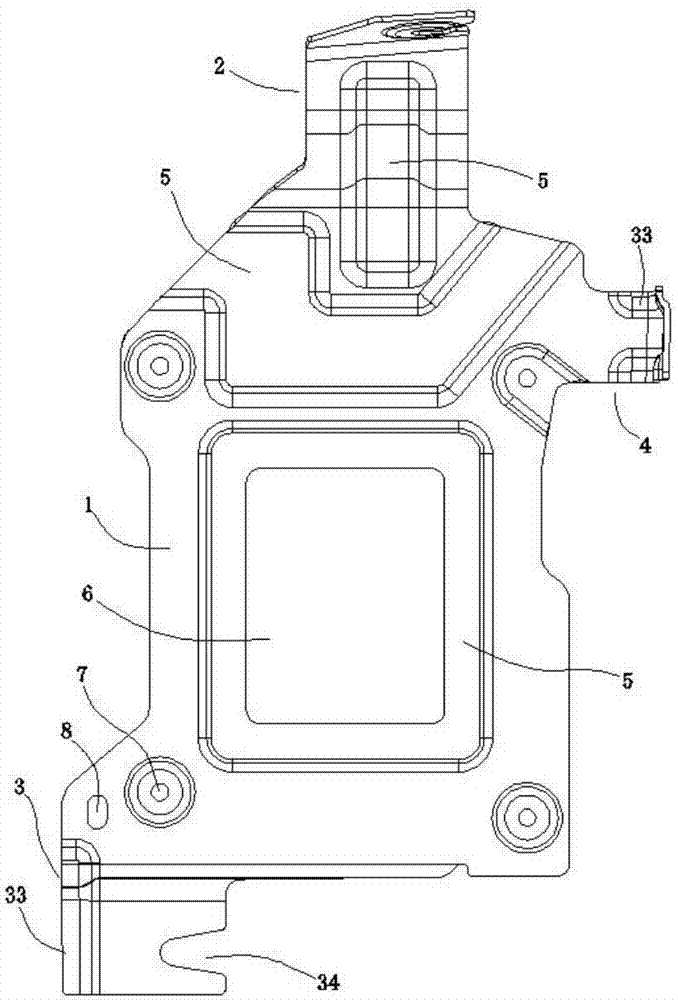

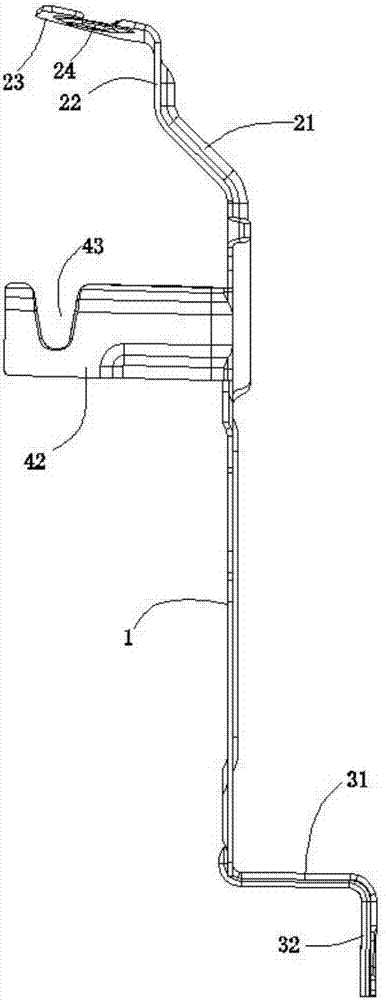

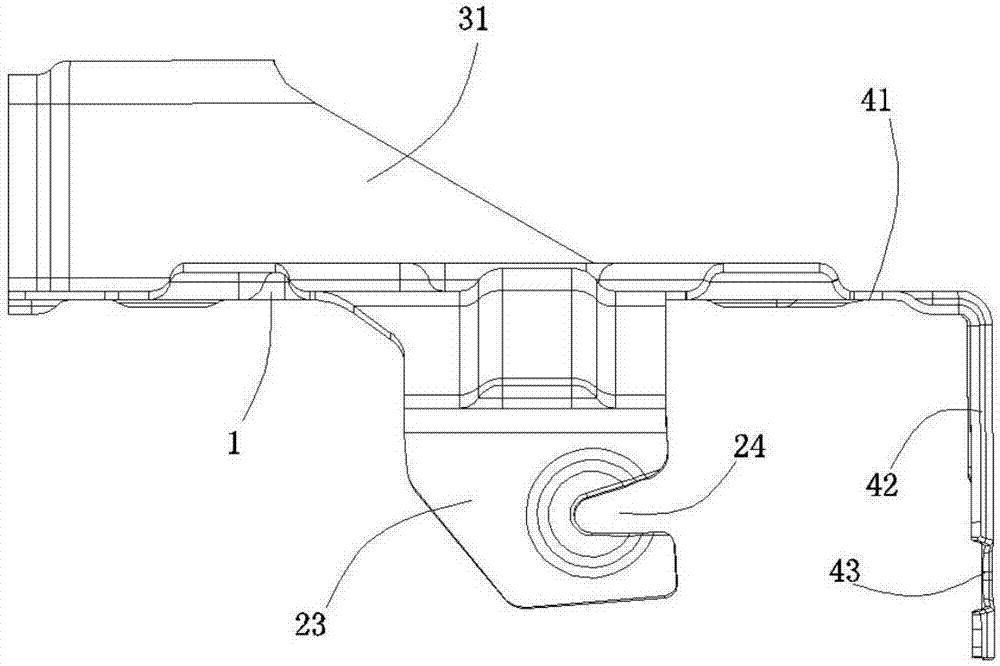

[0015] Example: such as Figure 1 to Figure 3 As shown, a power amplifier support frame of the present invention includes a sheet-shaped support frame main body 1, the upper middle part of the support frame main body 1 is provided with a first fixed foot 2 upward, and the lower end left side of the support frame main body 1 is provided with a second fixed foot downward. Two fixed feet 3, the upper end right side of the support frame main body 1 is upwardly provided with the third fixed foot 4, the upper end and the middle part of the support frame main body 1 are all provided with indentations 5 to increase the structural strength, and the middle part of the support frame main body 1 is provided with The square window 6 is provided with fixing holes 7 at four corners of the support frame main body 1 . The indentation 5 in the middle of the main body 1 of the support frame is a square indentation, the square window 6 is set in the square indentation, and the indentation 5 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com