Omeprazole enteric coated tablet and preparation method thereof

A technology for omeprazole intestine and omeprazole, applied in the field of medicine, can solve the problems of complex process parameters, easy to produce adhesion, poor reproducibility of industrialized production and the like, achieve simple process, ensure quality and curative effect, and be easy to operate and the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

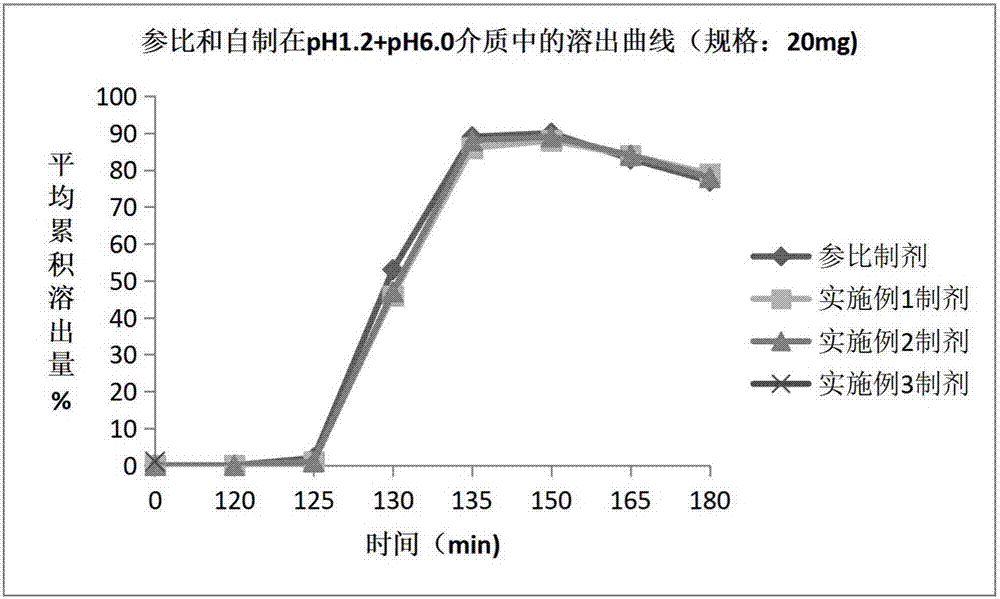

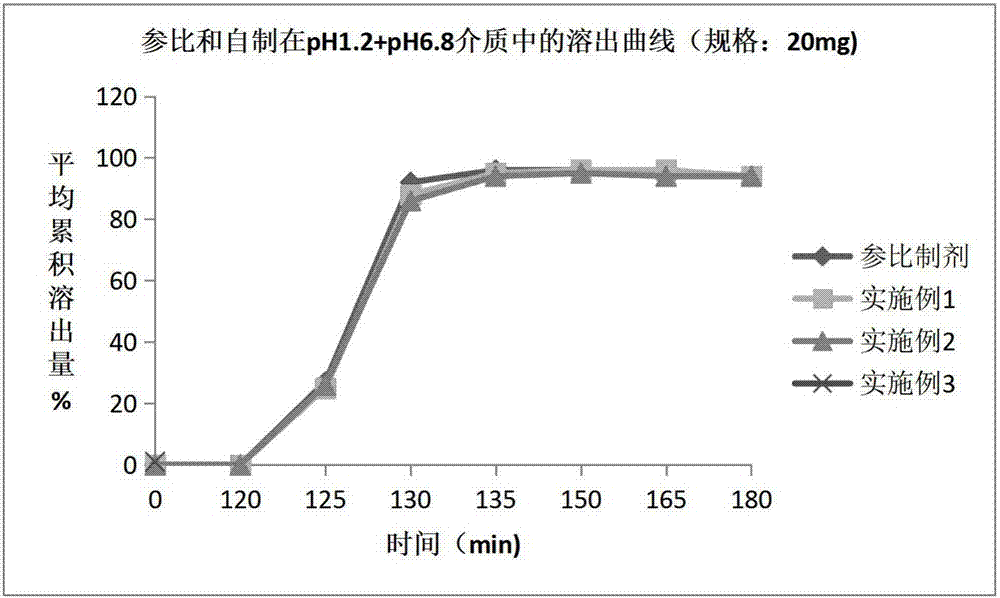

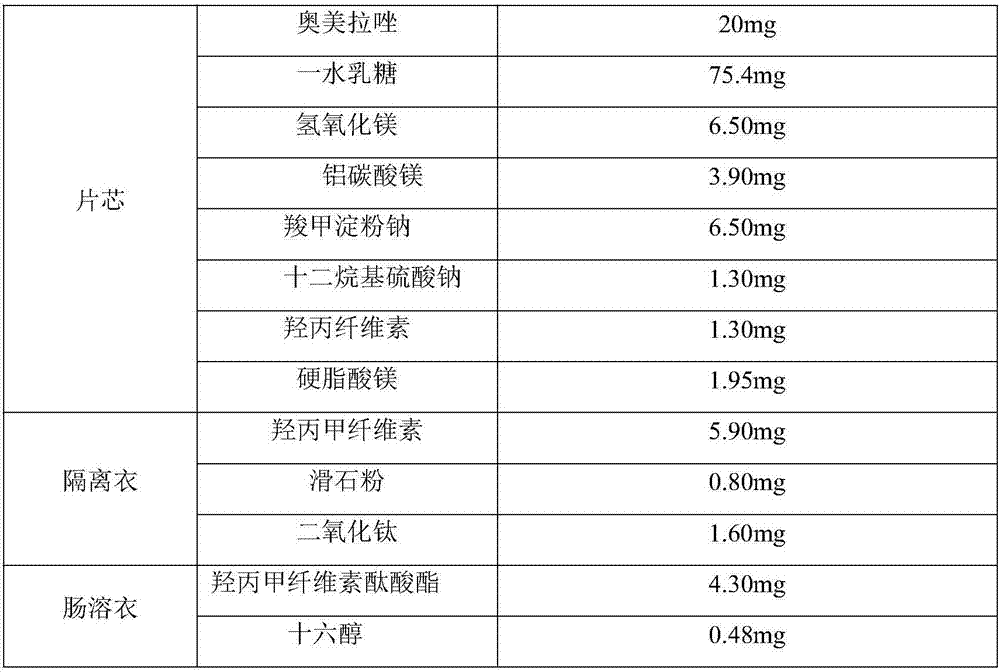

[0031] Taking omeprazole enteric-coated tablets with a dose of 20 mg as an example, the formula is as follows:

[0032]

[0033] Tablet core preparation: add a certain amount of 30% ethanol solution in a suitable container, add hypromellose to stir and dissolve, sodium lauryl sulfate is dissolved in the binder and added, pass the raw and auxiliary materials through a 40 mesh sieve, add high In the shearing wet granulator, stir at 200 rpm, mix for 3 minutes, under stirring, stir at 200 rpm and cutter at 1000 rpm, gradually add the binder to make soft materials for 3-5 minutes, to obtain suitable granules, fluidized bed drying, Set the inlet air temperature to 50°C, control the moisture content of the particles to be 2.5-3.5%, and use a granulator for granulation after drying. 20%, mix the granules and the auxiliary materials with a square cone, the rotation speed is 3-5rpm, the time is 2min, and the tablet is compressed by a high-speed rotary tablet machine, the hardness is ...

Embodiment 2

[0037] Taking omeprazole enteric-coated tablets with a dose of 20 mg as an example, the formula is as follows:

[0038]

[0039] Tablet core preparation: add a certain amount of 30% ethanol solution in a suitable container, add hypromellose to stir and dissolve, sodium lauryl sulfate is dissolved in the binder and added, pass the raw and auxiliary materials through a 40 mesh sieve, add high In the shearing wet granulator, stir at 200 rpm, mix for 3 minutes, under stirring, stir at 200 rpm and cutter at 1000 rpm, gradually add the binder to make soft materials for 3-5 minutes, to obtain suitable granules, fluidized bed drying, Set the inlet air temperature to 50°C, control the moisture content of the particles to be 2.5-3.5%, and use a granulator for granulation after drying. 20%, mix the granules and the auxiliary materials with a square cone, the rotation speed is 3-5rpm, the time is 2min, and the tablet is compressed by a high-speed rotary tablet machine, the hardness is ...

Embodiment 3

[0043] Taking omeprazole enteric-coated tablets with a dose of 20 mg as an example, the formula is as follows:

[0044]

[0045] Tablet core preparation: add a certain amount of 30% ethanol solution in a suitable container, add hypromellose to stir and dissolve, sodium lauryl sulfate is dissolved in the binder and added, pass the raw and auxiliary materials through a 40 mesh sieve, add high In the shearing wet granulator, stir at 200 rpm, mix for 3 minutes, under stirring, stir at 200 rpm and cutter at 1000 rpm, gradually add the binder to make soft materials for 3-5 minutes, to obtain suitable granules, fluidized bed drying, Set the inlet air temperature to 50°C, control the moisture content of the particles to be 2.5-3.5%, and use a granulator for granulation after drying. 20%, mix the granules and the auxiliary materials with a square cone, the rotation speed is 3-5rpm, the time is 2min, and the tablet is compressed by a high-speed rotary tablet machine, the hardness is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screen aperture | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com