A kind of automobile decorative strip and its surface treatment method

A technology for automobile decoration and surface treatment, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, vehicle parts, etc. It can solve the problems of high processing cost, low product qualification rate, and difficult paint layer processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

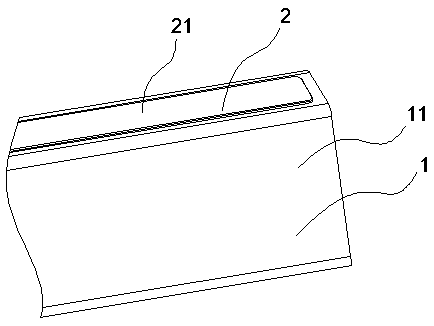

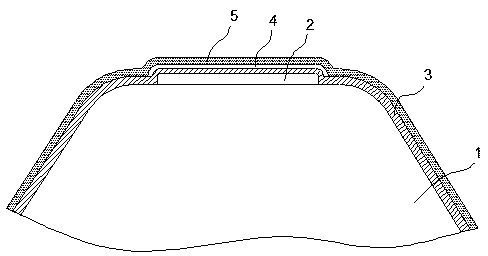

[0027] A car trim, such as figure 1 with figure 2 As shown, it includes a substrate body 1 and a boss 2, the boss 2 includes a table top 21, the substrate body 1 includes an outer end surface 11, and the surface of the substrate body 1 is sequentially provided with a primer layer 3 and a topcoat layer 5 from inside to outside. , the surface of the boss 2 is sequentially provided with a primer layer 3, a hot stamping layer 4 and a topcoat layer 5 from the inside to the outside. The thickness of the primer layer 3 on the substrate body 1 is 15-25 μm, and the primer layer on the boss 2 3 has a thickness of 10-15 μm, and the topcoat layer 5 has a thickness of 20-30 μm. The outer end surface 11 is disposed on both sides of the boss 2 opposite to the table surface 21 , and the outer end surface 11 is inclined relative to the table surface 21 . The thickness of the boss 2 is greater than 0.5mm.

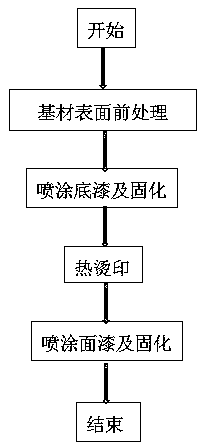

[0028] Such as image 3 Shown, a kind of automobile decorative strip surface treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com