Novel high-strength packaging box

A high-strength, new technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of difficult handling, inconvenient packaging of precision instruments, etc., to achieve the effect of convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

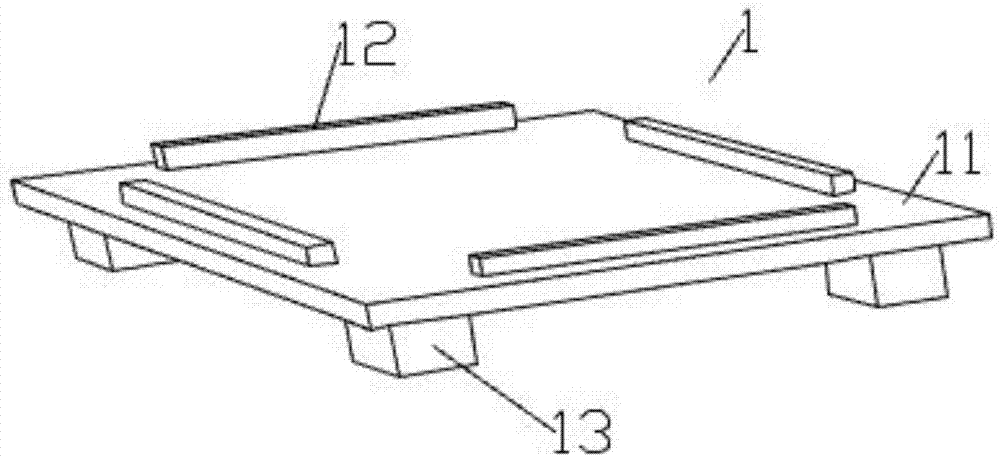

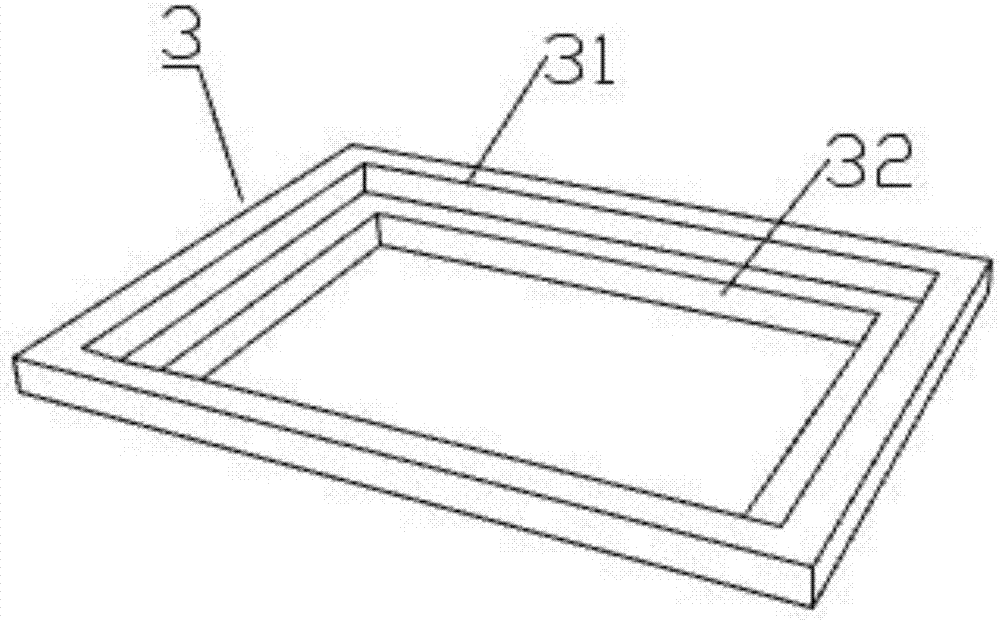

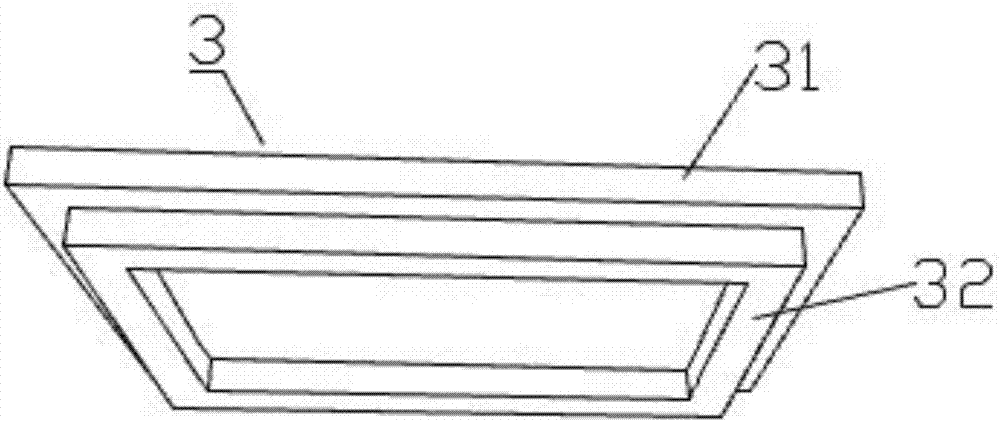

[0034] Such as Figure 1-6 As shown, a novel high-strength packing case of the present invention comprises a case base 1, a shock absorbing pad 3 placed on the case base 1 and a case cover 2 placed on the case base 1, the shock absorbing pad 3 and the case cover 2 They are all in contact with the box base 1, and the shock absorbing pad 3 is located in the box cover 2. The box base 1 includes a rectangular bottom plate 11, a limit block 12 fixed on the bottom plate 11 parallel to the four sides of the bottom plate 11 and fixed on the bottom of the bottom plate 11. The bearing 13 on the four corners, the shock absorber 3 includes a first square ring foam board 31 and a second square ring foam board 32 integrally formed, the first square ring foam board 31 is placed on the base plate 11, the second square ring foam board 31 The square ring foam board 32 is placed on the limit block 12, the case cover 2 is an open box body, the opening of the case cover 2 faces downward, the limit...

Embodiment 2

[0036] Such as Figure 7 As shown, Example 2 improves the structure of the box base 1 on the basis of Example 1. The box base 1 also includes two parallel support plates 14, and the two ends of the support plates 14 are fixed on the bottom of the two supports 13. The setting of the support plate 14 can be placed more stably when the present invention is stacked up and down, preventing the present invention from falling down and damaging precision instruments because a support 13 is not put in place.

Embodiment 3

[0038] Such as Figure 8 As shown, embodiment 3 continues to improve the structure of the box base 1 on the basis of embodiment 2, and the bottom plate 11 is also provided with a limit cardboard 15, which is a box body with open ends at both ends, and the limit cardboard 15 is fixed At the edge of the bottom plate 11 , the limiting cardboard 15 is located on the periphery of the box cover 2 . The setting of the limit cardboard 15 makes the placement of the case cover 2 more stable, and the case cover 2 is difficult to move between the limit cardboard 15 and the limit block 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com