Piled brick pillar loading and unloading rotary arm device for truck

A technology of rotating arm and coding bricks, which is applied to the arrangement of loading and unloading vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of slow speed, large space for lifting and low work efficiency, etc., and achieves cost reduction, easy promotion and popularization. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

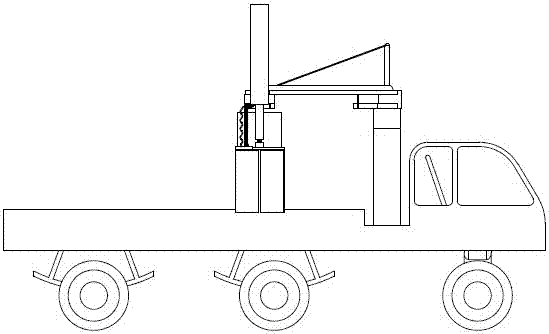

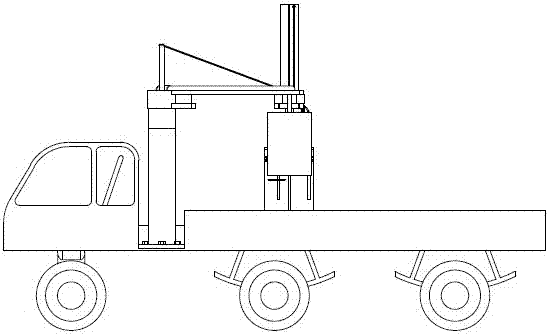

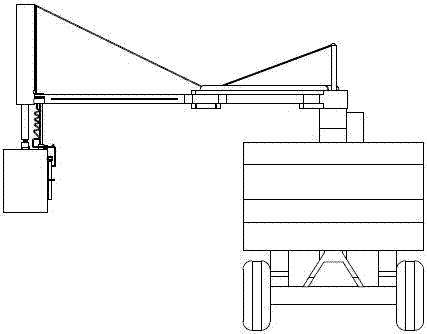

[0031] Example: refer to Figure 10 , Figure 11 , Figure 14 with Figure 15 As shown, the use of vehicle-mounted brick loading and unloading equipment solves the problem of manual loading and unloading of red bricks during transportation for a long time. The vehicle is equipped with a rotating arm device for loading and unloading brick stacking. The power of the oil cylinder is large, the speed is fast, and it is safe, efficient and labor-saving.

[0032] The vehicle-equipped loading and unloading brick stacking rotary arm device is characterized in that three pressure bearing sleeves 2 are made on the force arm 2 and force arm 3, and three pressure bearings are installed on the inner side of the three pressure bearing sleeve 2, and the pressure bearing A, pressure bearing B and pressure bearing C, moment arm one, moment arm two and moment arm three are connected together by fixed nut two, moment arm two and moment arm three can rotate on the axle of fixed nut two.

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap