Brick clamping device

A technology for clamping bricks and oil cylinders, applied in the direction of lifting devices, etc., can solve the problems of low work efficiency, slow speed, and large clamping space, and achieve the effect of improving work efficiency, reducing costs, and being easy to popularize and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

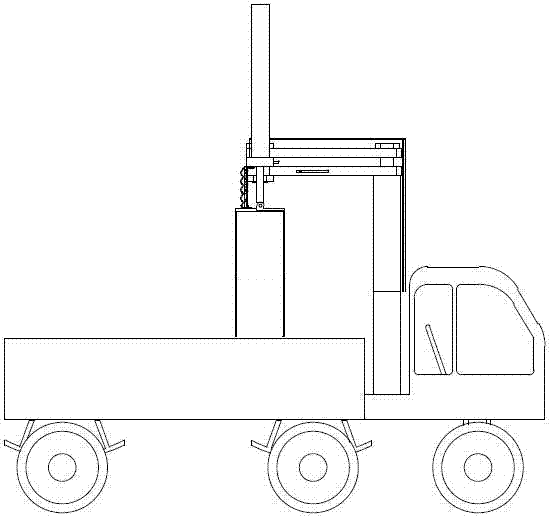

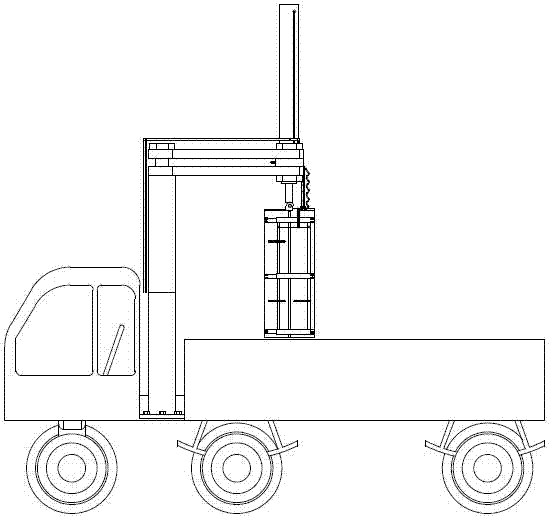

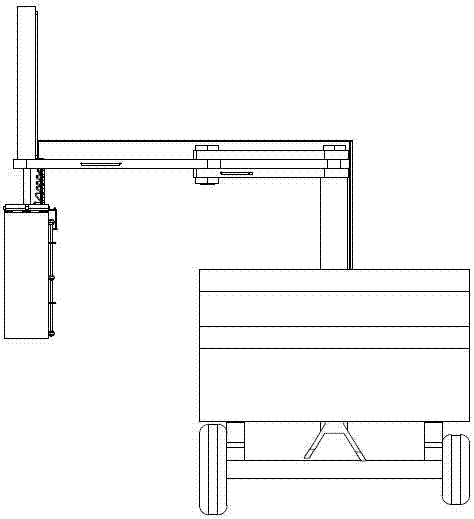

[0038] Example: refer to Figure 14 , Figure 16 and Figure 17 As shown, the use of vehicle-mounted brick loading and unloading equipment solves the problem of manual loading and unloading of red bricks during reloading and transportation for a long time. The brick clamping device and the rotating arm can be lifted and rotated at 180 degrees on the upper part of the carriage, occupying a small space, and the power of the hydraulic cylinder is large. Fast, safe, efficient and labor-saving,

[0039] The rotating arm system can stack bricks in different areas. In order to load bricks in brick factories and original brick stacks and unload bricks in different sites, the automatic side brick clamping machine clamps bricks from the side of the brick stack, and the two-way hydraulic cylinder controls the horizontal direction. The brick clamping force is strong, the movement is convenient and fast, the lifting type does not drop the bricks, and the bricks can be stacked after unloa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap