Polypropylene composite material with low volatile organic compound (VOC), high strength and flame retardance and preparation method thereof

A flame retardant polypropylene and composite material technology, applied in the field of flame retardant composite materials, can solve problems such as harming human health, affecting the mechanical properties of composite materials, human body and environmental hazards, etc., achieving low VOC, simple and easy preparation process, and improving The effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

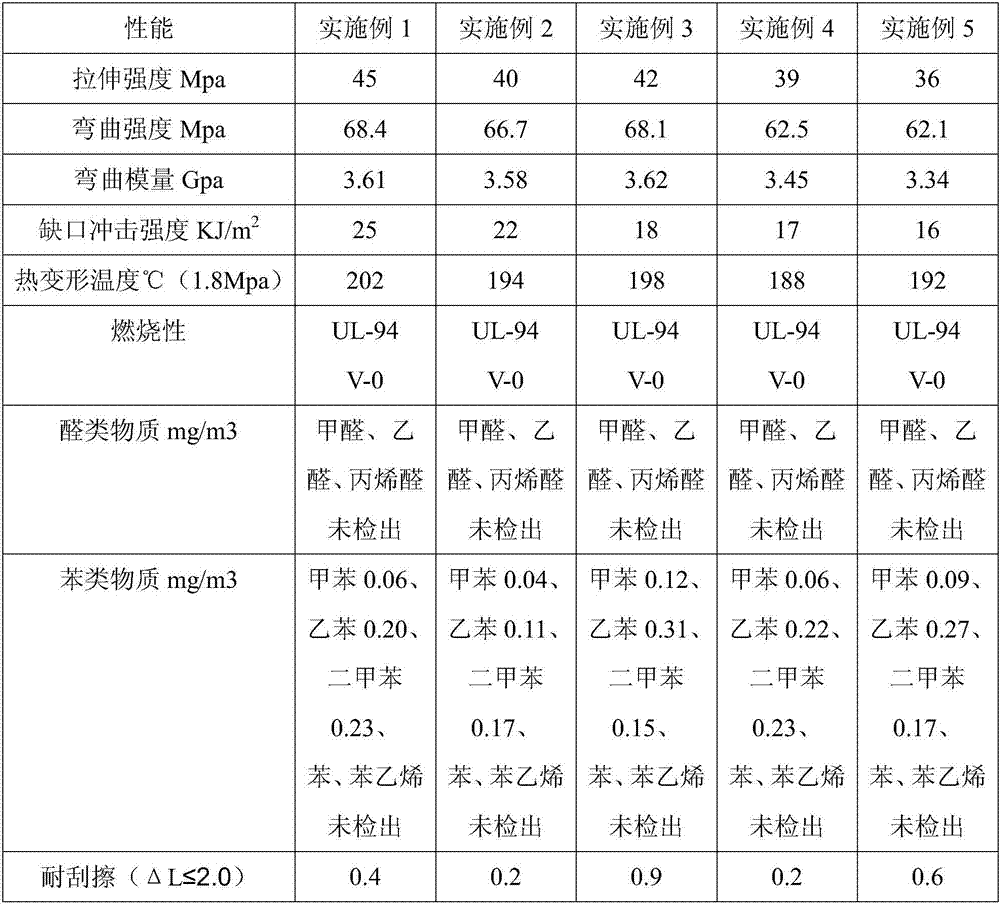

Examples

Embodiment 1

[0028] Low-VOC, high-strength, flame-retardant polypropylene composite material, its raw materials are composed of the following components in parts by weight: 66 parts of copolymerized polypropylene, 16 parts of homopolypropylene, 4 parts of tantalum carbide (the average particle size is preferably 20 ~200 nanometers, specific surface area 12~38m 2 / g), 6 parts of tantalum hydroxide (average particle size is 55-260 microns, aspect ratio is 120:1-220:1, specific surface area is 2-8m 2 / g), 4 parts of glass fiber, 3 parts of POE elastomer, 0.3 part of silane coupling agent KH560, 0.5 part of anti-dripping agent polytetrafluoroethylene, 0.2 part of antioxidant tetrakis[β-(3,5-ditertiary Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0029] The preparation method is as follows:

[0030] 1) The coupling agent is formulated into a coupling agent ethanol solution of 1 to 3 wt%, and the dosage of the coupling agent is 0.15% of the weight of the tantalum carbide; the ta...

Embodiment 2

[0039] Low-VOC, high-strength, flame-retardant polypropylene composite material, its raw materials are composed of the following components in parts by weight: 56 parts of copolymerized polypropylene, 21 parts of homopolypropylene, 8 parts of tantalum carbide (the average particle size is preferably 20 ~200 nanometers, specific surface area 12~38m 2 / g), 10 parts of tantalum hydroxide (average particle size is 55-260 microns, aspect ratio is 120:1-220:1, specific surface area is 2-8m 2 / g), 1 part of glass fiber, 3 parts of SBS elastomer, 0.3 part of silane coupling agent KH560, 0.5 part of anti-dripping agent polytetrafluoroethylene, 0.2 part of antioxidant tetrakis[β-(3,5-ditertiary Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0040] The preparation method is as follows:

[0041] 1) The coupling agent is formulated into a coupling agent ethanol solution of 1 to 3 wt%, and the dosage of the coupling agent is 0.15% of the weight of the tantalum carbide; the ta...

Embodiment 3

[0050]Low-VOC, high-strength, flame-retardant polypropylene composite material, its raw materials are composed of the following components in parts by weight: 72 parts of copolymerized polypropylene, 13 parts of homopolypropylene, 2 parts of tantalum carbide (the average particle size is preferably 20 ~200 nanometers, specific surface area 12~38m 2 / g), 3 parts of tantalum hydroxide (average particle size is 55-260 microns, aspect ratio is 120:1-220:1, specific surface area is 2-8m 2 / g), 6 parts of glass fiber, 3 parts of SEBS elastomer, 0.3 part of silane coupling agent KH560, 0.5 part of anti-dripping agent polytetrafluoroethylene, 0.2 part of antioxidant tetrakis[β-(3,5-ditertiary Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0051] The preparation method is as follows:

[0052] 1) The coupling agent is formulated into a coupling agent ethanol solution of 1 to 3 wt%, and the dosage of the coupling agent is 0.15% of the weight of the tantalum carbide; the ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap