Safety monitoring system for coal mine

A monitoring system and technology for coal mine safety, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve problems such as failure to meet coal mine safety monitoring requirements, single function, etc., to ensure safety, a high degree of integration, and good comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

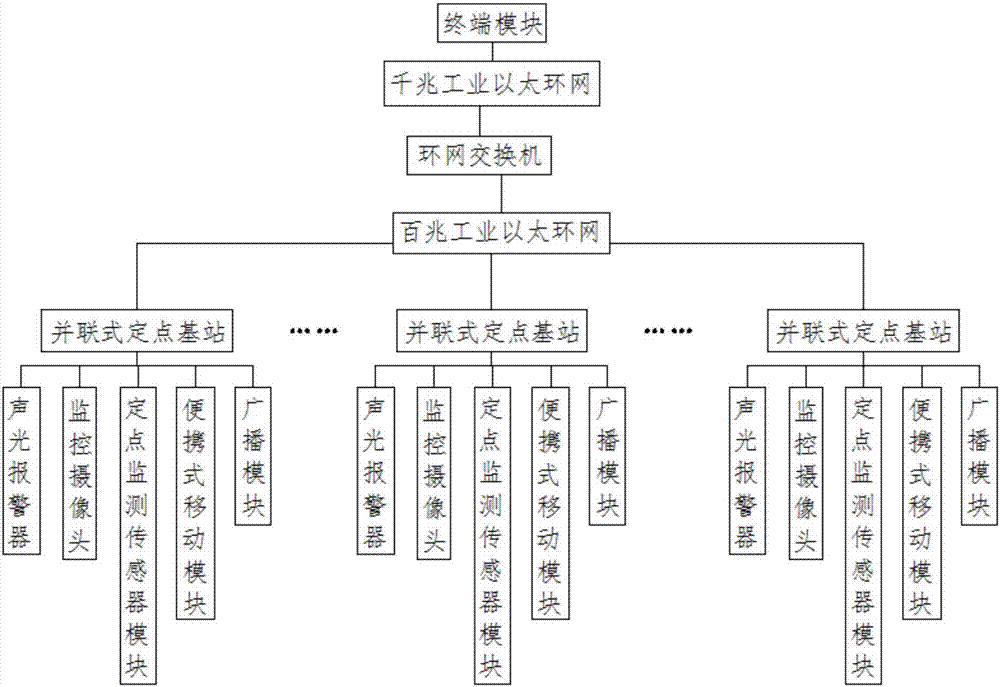

[0020] Such as figure 1 As shown, a coal mine safety monitoring system includes a parallel fixed-point base station set at various fixed-point locations in the coal mine, and the parallel fixed-point base station is connected to an audible and visual alarm and / or a surveillance camera and / or a fixed-point monitoring sensor module and / or a portable mobile Modules and / or broadcast modules, parallel fixed-point base stations are connected to Fast Industrial Ethernet, Fast Industrial Ethernet is connected to Gigabit Industrial Ethernet through a ring network switch, and Gigabit Industrial Ethernet is connected to terminal modules. The terminal modules are for the entire monitoring system. control center. When the monitoring environment is abnormal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com