Structure-improved liquid valve

A liquid and valve technology, applied in the field of valve control, can solve the problems of long switching time, imprecise closure, high manufacturing cost, etc., and achieve the effects of low manufacturing cost, avoiding waste, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

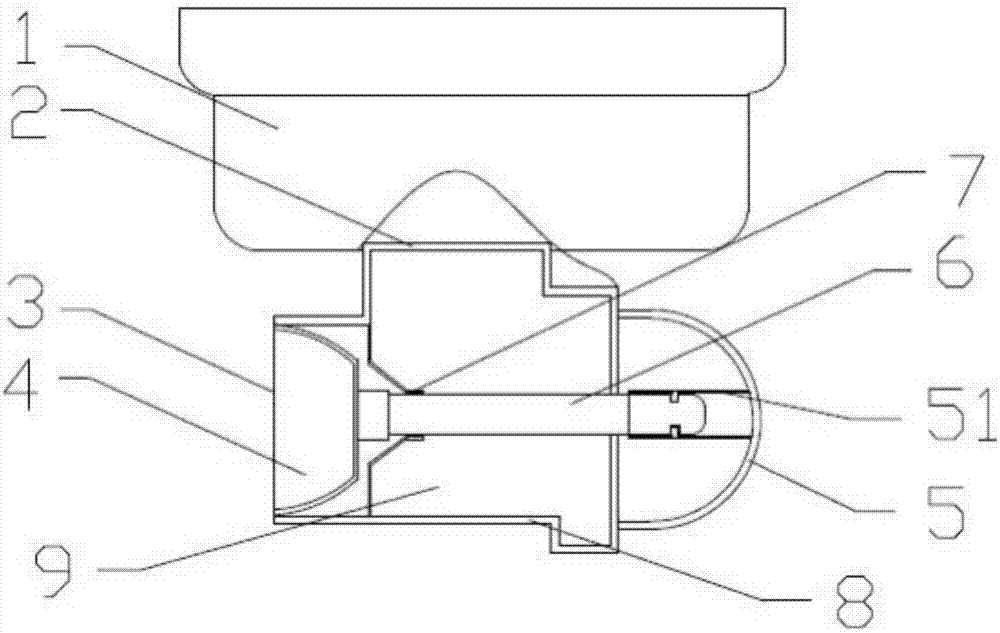

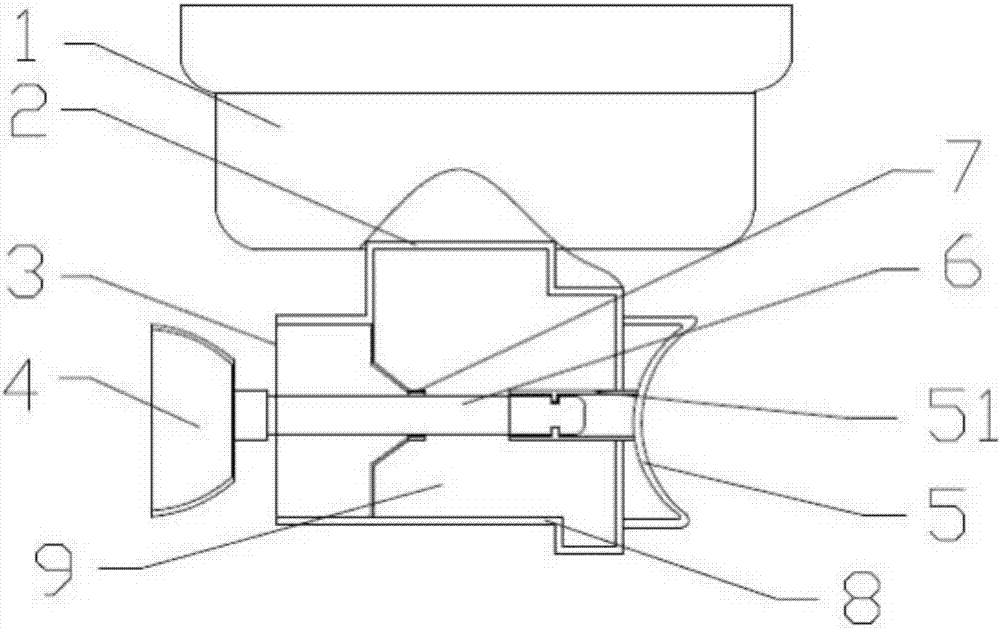

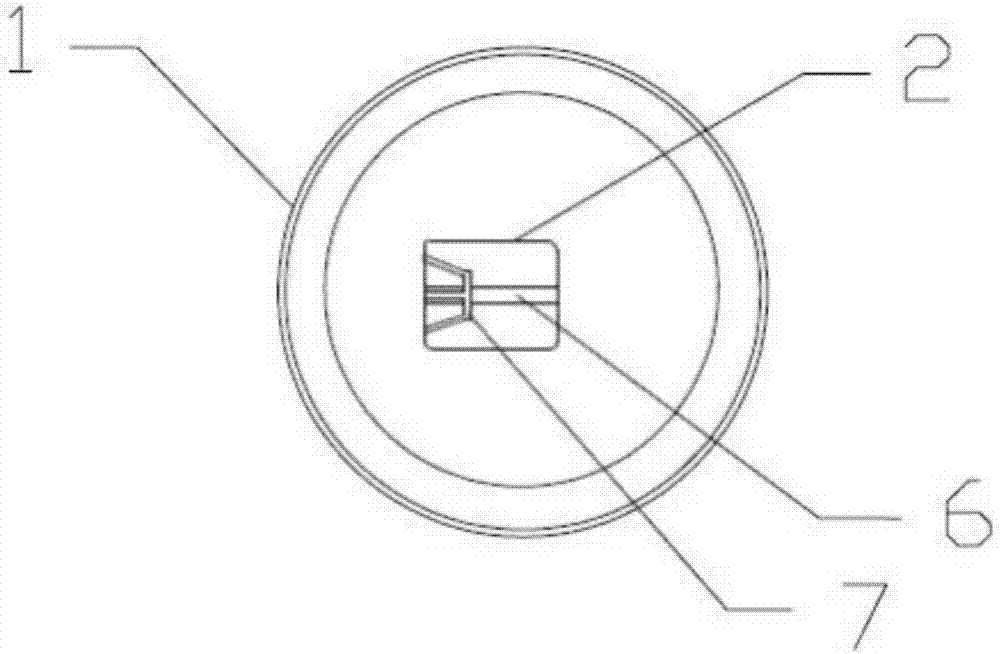

[0023] like Figure 1-4 As shown, a liquid valve with improved structure in this embodiment includes a connection cover 1 threadedly connected with the volume body, a valve body 8 fixedly connected with the connection cover 1, the inside of the valve body 8 is a cavity 9, and the connection cover 1 and The valve body 8 communicates with the liquid inlet port 2, and also includes a liquid outlet port 3 arranged on the valve body 8, and a bowl-shaped sealing valve plate 4 matched with the liquid outlet port 3, which is axially limited and sealed with the valve body. Connect the sealing valve plate 4 and the connecting rod 6 of the elastic gland 5 to the elastic gland 5 on the valve body 8 at the other end away from the liquid outlet 3 .

[0024] The valve body 8 at the other end away from the liquid outlet is provided with a sealing groove, and the elastic gland 5 is connected with the valve body 8 through the sealing groove. The sealing groove is an axial annular groove, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com