Ultrasonic cleaning device of color separation plate of offset printing press

A technology of ultrasonic cleaning and color separation plate, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of poor cleaning effect and long use time, and achieve easy mastery and easy operation of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

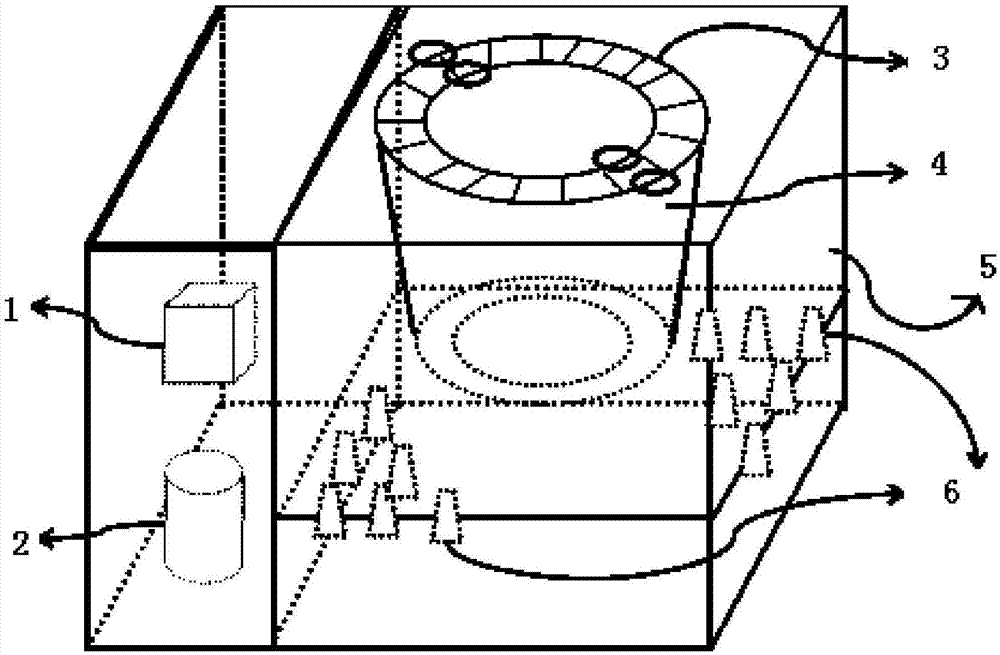

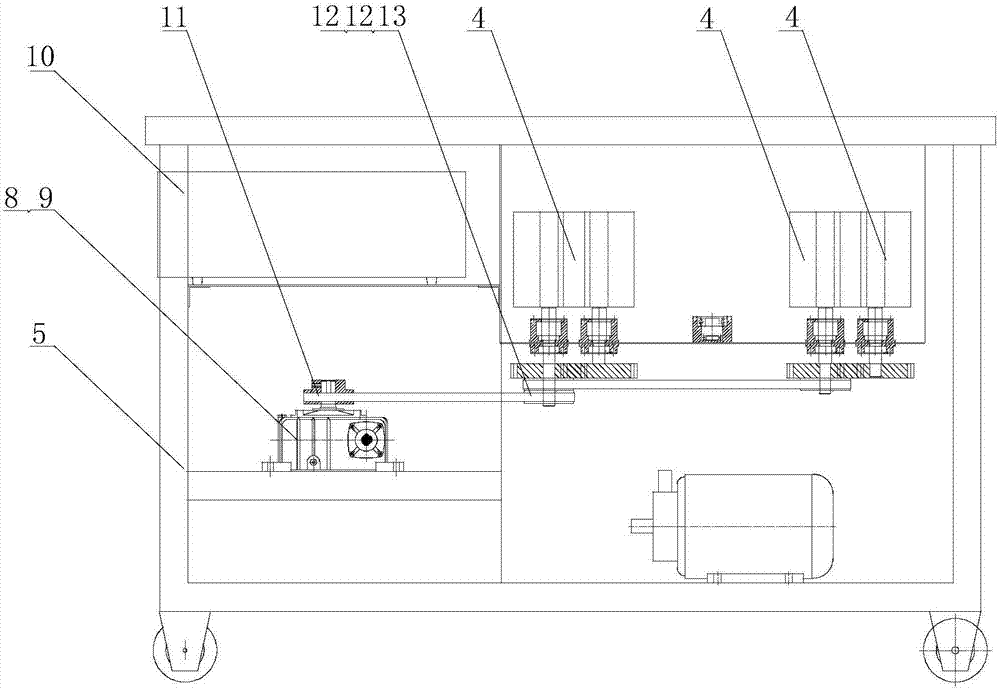

[0035] 1) The manufactured ultrasonic cleaning machine for color separation plates works with a 220V power supply, which is versatile and can meet the cleaning requirements for color separation plates of four types of offset printing equipment.

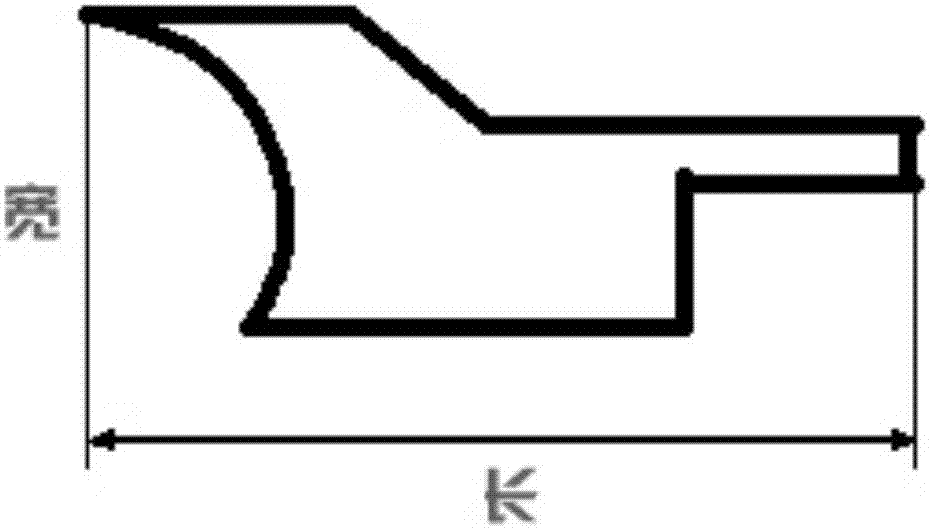

[0036] The analysis of the cleaning objects is as follows: The material of the offset printing color separation plate is mainly non-metallic materials such as rubber and silica gel, which is characterized by being soft. The color separation boards are basically flakes, but there are many kinds of color separation boards with different shapes in the factory, and there are 4 types after investigation. The appearance diagram of the color separation board is shown in Figure 3 and the specifications and dimensions are shown in Table 1:

[0037] Table 1 Specifications of color partitions (unit: mm)

[0038] Variety

long

width

thick

Type A

230

85

9

Type B

220

90

10

Type C

210

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com