Workpiece conveying device for jet printing of regular-geometric-shaped workpieces

A transmission device and geometric shape technology, which is applied in the field of workpiece transmission devices, can solve the problems of scrapped regular geometric workpieces, unlocated regular geometric workpieces, and workpiece conveying devices lacking positioning functions, etc., to achieve simple structure, reduce scrap rate, Create a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

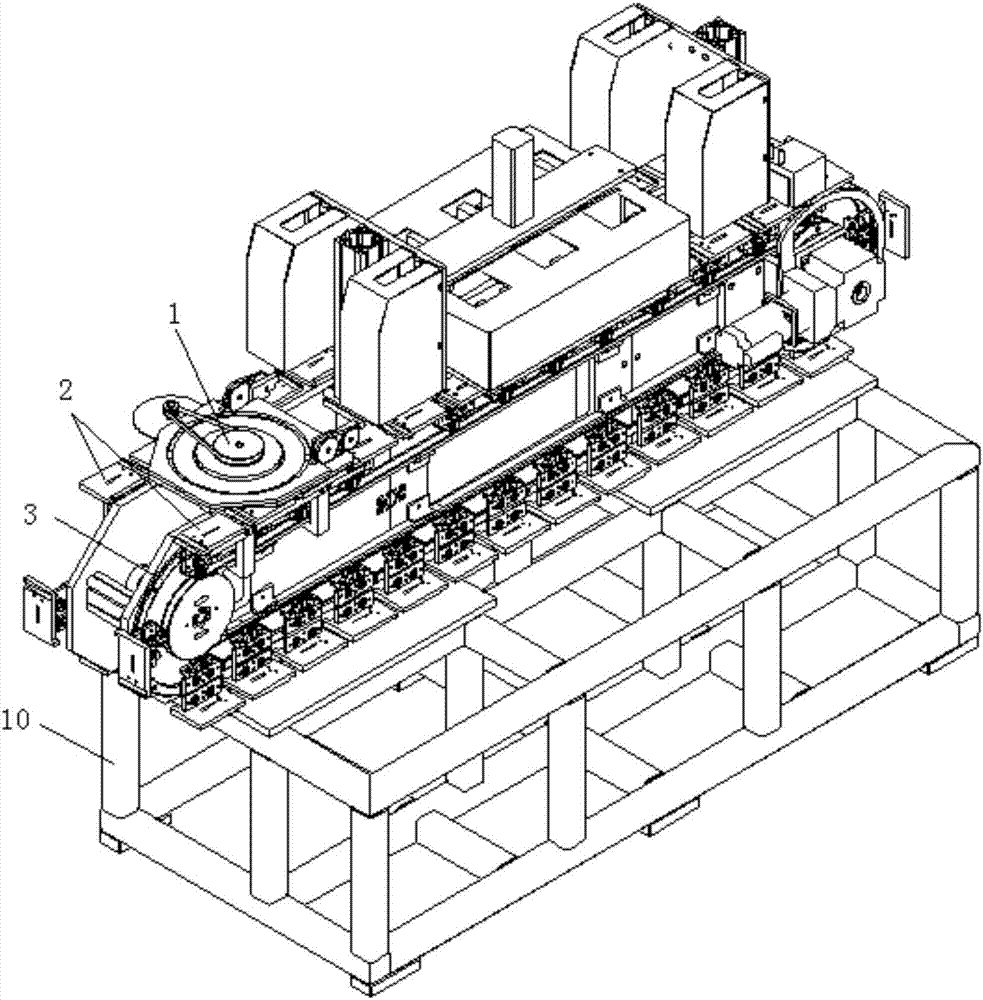

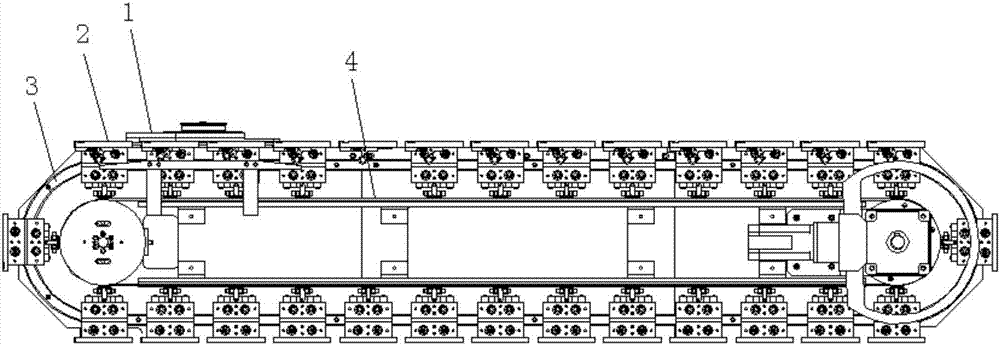

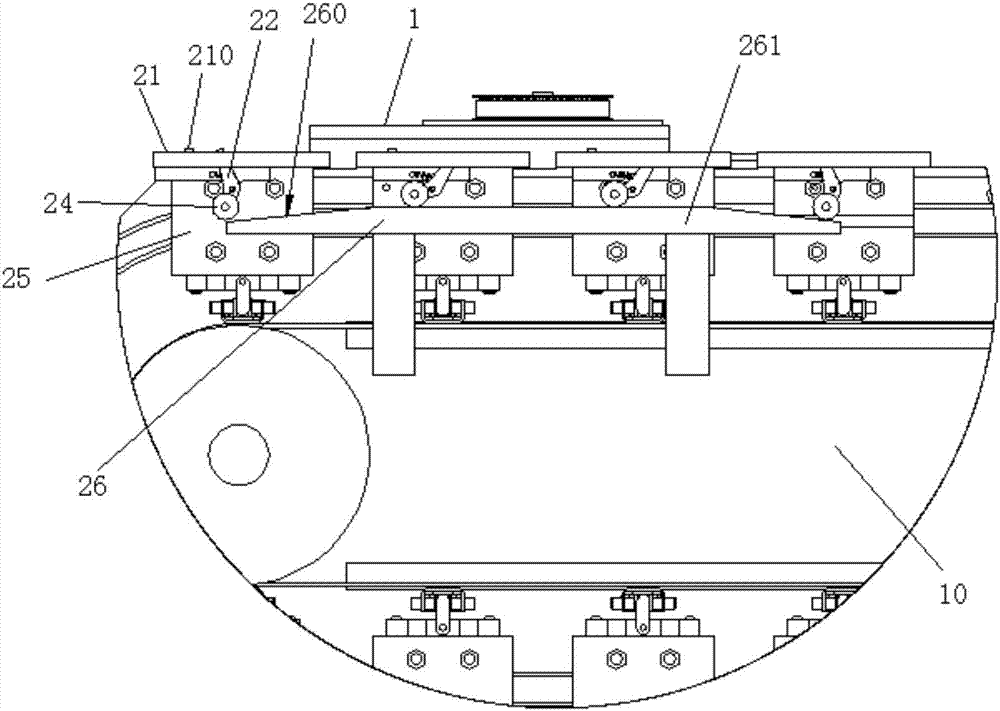

[0023] like figure 1 and figure 2 , the workpiece conveying device for regular geometric workpiece printing of the present invention is located on the frame 10 and mainly consists of the clamp body 2, the ring guide rail 3, the endless conveyor belt and the driving plate 26 for opening the clamp body 2. A plurality of clip bodies 2 are separately arranged on the guide rail 3 at a certain interval, and adjacent clip bodies are closely connected to each other, so that they are evenly arranged on the annular rail 3 . The endless conveyor belt is arranged in the circular guide rail and connected with the clamp body 2 to drive the clamp body 2 to move along the circular guide rail. The driving plate 26 is arranged on the inner side of the circular guide rail 3 and contacts with the clamp body 2 moving with the endless conveyor belt. to open the clamp body. A regular geo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com